Bakery Chiller Models PMC 40/50 and PMC 70/120

Effective February 23, 1999

Installation and Operation Instructions, Part No. 9842311

Revised May 7, 2009

SECTION 2.0 - INSTALLATION

2.1 Inspection

Because it is possible for equipment to be damaged during shipment, we recommend that you make a

thorough inspection of all equipment before it is unloaded from the freight truck. Carefully inspect

equipment for hidden damage. It may be difficult to collect for damage if it is not found prior to

unloading. It is very important to note any damage on the bill of lading and have the driver sign it.

2.2 Safety

Installation and service should be performed by an authorized service technician who has the proper

training to install and service refrigeration equipment. Effective November 1994, the service technician

must be certified in refrigerant usage by an EPA-approved testing organization prior to installing or

servicing any refrigeration equipment.

All electrical connections must be performed by a qualified electrician in accordance with local and

NEC regulations.

2.3

Location

When choosing a location for the Mueller bakery chiller, consider these items:

•

Environment:

An indoor location will be necessary where the chiller section is protected from

freezing temperature.

•

Serviceability:

The chiller should be located with the circulating pump and the control panel

accessible for service. Keep in mind the chiller will require field connections to the main electrical

supply and water supply line. The chiller should be located close to a drain for service and

cleaning.

•

Refrigeration Unit:

The refrigeration unit (for PC and RC models) must be located where they are

protected from the environment and have adequate air-flow for the condenser. Be especially

cautious of conditions that would allow dust or oil to enter the condenser.

•

Efficiency:

Locate the chiller as close as possible to point of use for chilled water.

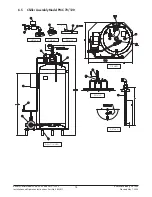

2.4 Chilled Water Piping

The bakery chiller supply water should be connected to the

3

/

4

" inlet water solenoid valve located at

the top of the water tank (refer to Figure 3, “Flow Diagram”). The supply water line should be taken

from a source that provides adequate water flow and a minimum of

3

/

4

" in size. It is recommended that

a full flow shut-off valve and union be installed just prior to the solenoid valve for service.

The chilled water supply should be connected to the

3

/

4

" chilled water outlet located near the

circulation pump. Keep this line as short as possible to allow for chilled water of desired temperature

to be provided to point(s) of use. This line should be insulated to reduce external heat gain to the

chilled water.

Check all piping for leaks and repair if required. Clean and rinse lines and water storage tank prior to

usage.

3