Bakery Chiller Models PMC 40/50 and PMC 70/120

Effective February 23, 1999

Installation and Operation Instructions, Part No. 9842311

Revised May 7, 2009

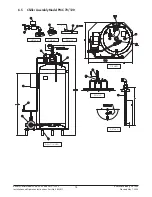

2.5

Refrigeration Unit Installation

All refrigerant piping should be in accordance to acceptable refrigeration practices. Distance between

refrigeration unit and bakery chiller assembly should be as close as possible. Long distance piping and

risers may require attention to reduce restriction of refrigerant flow and to provide adequate oil return.

The liquid line should be

3

/

8

" OD copper pipe and the suction line

7

/

8

" OD copper pipe. A liquid line

drier of adequate size should be installed on all PMC 40/50 RS and RC models. A liquid line drier is

provided on 3.5 hp. units for PMC 70/120 RS and RC models. A liquid line sight glass should be

installed just prior to the thermal expansion valve (TEV) on the bakery chiller evaporator assembly.

Attach the thermal expansion valve sensing bulb to the suction line and insulate after refrigerant lines

are installed as shown in Section 7.3 and Figure 7.

Evacuation to 500 microns prior to charging with refrigerant is required. The system must hold 1,000

microns in a standing vacuum test, ensuring that it is leak free.

Refrigerant charging should be through the suction service valve in vapor form only. Charge with an

adequate amount of refrigerant prior to starting the compressor and make sure that water storage tank

is filled with water. Refer to Section 3.0 for start-up procedures.

The initial refrigerant charge for PMC 40/50 model with a 2 hp unit is 6 lbs R-22 or 5 lbs. R-507

refrigerant. The initial refrigerant charge for PMC 70/120 models with a 3.5 hp unit is 13 lbs R-22 or 12

lbs. R-507 refrigerant.

4