18

Zipper sewing

secure the button.

6. Rotate the Hand Wheel (23) to raise the Needle to the highest point then

raise the Presser foot lifter (33).

7. Pull out the fabric and cut the threads.

NOTE:

If you are having difficulties removing the fabric from underneath the

Feed dog (12), push and hold the Thread clamp (17) to the left while pulling

the fabric at the same time. Alternatively, you can rotate the Hand Wheel

(23) counterclockwise (toward you) until you pull the thread and take out

the fabric.

8. To ensure that the button stays attached to the fabric, bring all the loose

threads to the back of the fabric. You can do that by passing them (one by

one) through the eye of a regular sewing needle and pushing the needle

through to the back of the fabric.

9. Tie a knot with the loose threads to secure the button and then cut off the

excess threads.

10. Repeat steps 5-9 on the remaining holes if the button has more holes.

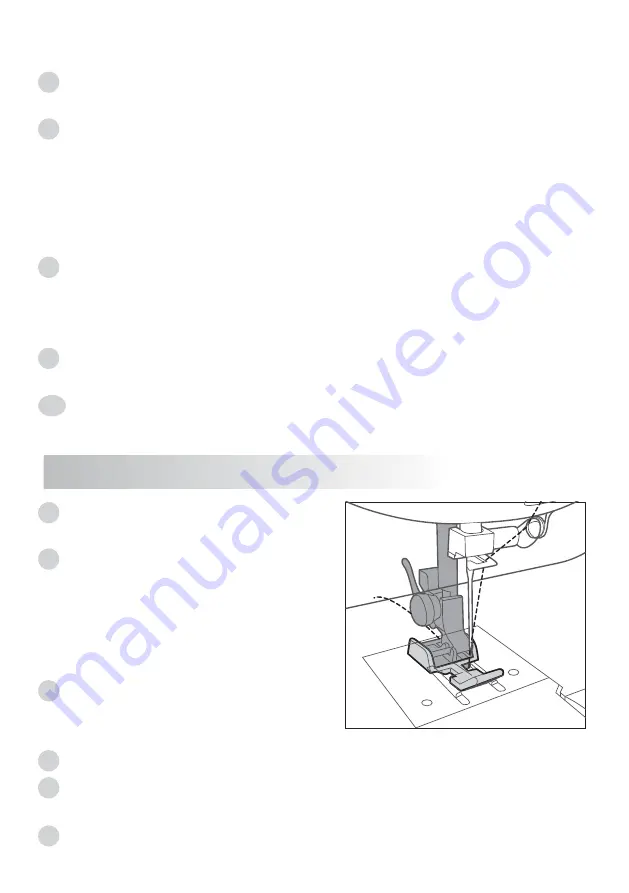

1. Pin or baste the zipper (not included)

to the fabric.

2. Remove the Presser foot (4) - for

instructions on how to remove the

Presser foot, refer to the section

“Removing or attaching the Presser

foot” on page 20 of this instruction

manual

3. Attach the right side of the Zipper

presser foot (38) to the Presser foot

holder (3).

4. Set the sewing machine to stitch pattern 1A, 2A, or 3A.

5. Align the teeth of the zipper next to the right edge of the Zipper presser

foot (38).

6. Sew a seam all the way down the zipper. Take out the fabric and cut the

threads.

Summary of Contents for ULTRA-STITCH SM-1100

Page 27: ......