M

UGNAI N I

®

MUGNAINI SERIES

GAS FIRED OVEN MANUAL

Mugnaini Imports, Inc.

11 Hangar Way, Watsonville CA 95076

888.887.7206 │ 831.761.7167 │ Fax: 831.728.5570

www.mugnaini.com │ mugnaini@mugnaini.com

PAGE 12

7. INDIRECT VENTING

7.1 INDIRECT VENTING REQUIREMENTS

•

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE

•

Oven installations using indirect venting require a Type 1 Hood listed to UL 710

•

The hood shall allow adequate clearance for removal and cleaning of the grease baffles (Captive

Aire model SND is a low profile hood that enhances access)

•

Fire suppression system shall be used in the hood only and not pointed into the oven

•

Flue outlet temperatures reach 550 F so be sure to place fusible link appropriately

•

May be vented with single wall grease duct or insulated factory built grease duct list to UL 1978

•

Example grease duct: Metal Fab G-Series www.metal-fabinc.com

•

Exhaust fan listed for use with a wood burning oven is recommended. The Enervex GSV series fan is

listed for use with a wood burning pizza oven see: http://www.greasefans.com

7.2 TYPE 1 HOOD

•

Minimum Type 1 Hood dimensions: 36” wide x 42” deep

•

Example: Captive Aire model SND Exhaust Hood www.captiveaire.com

•

Install hood directly on top of oven using ceiling supports

•

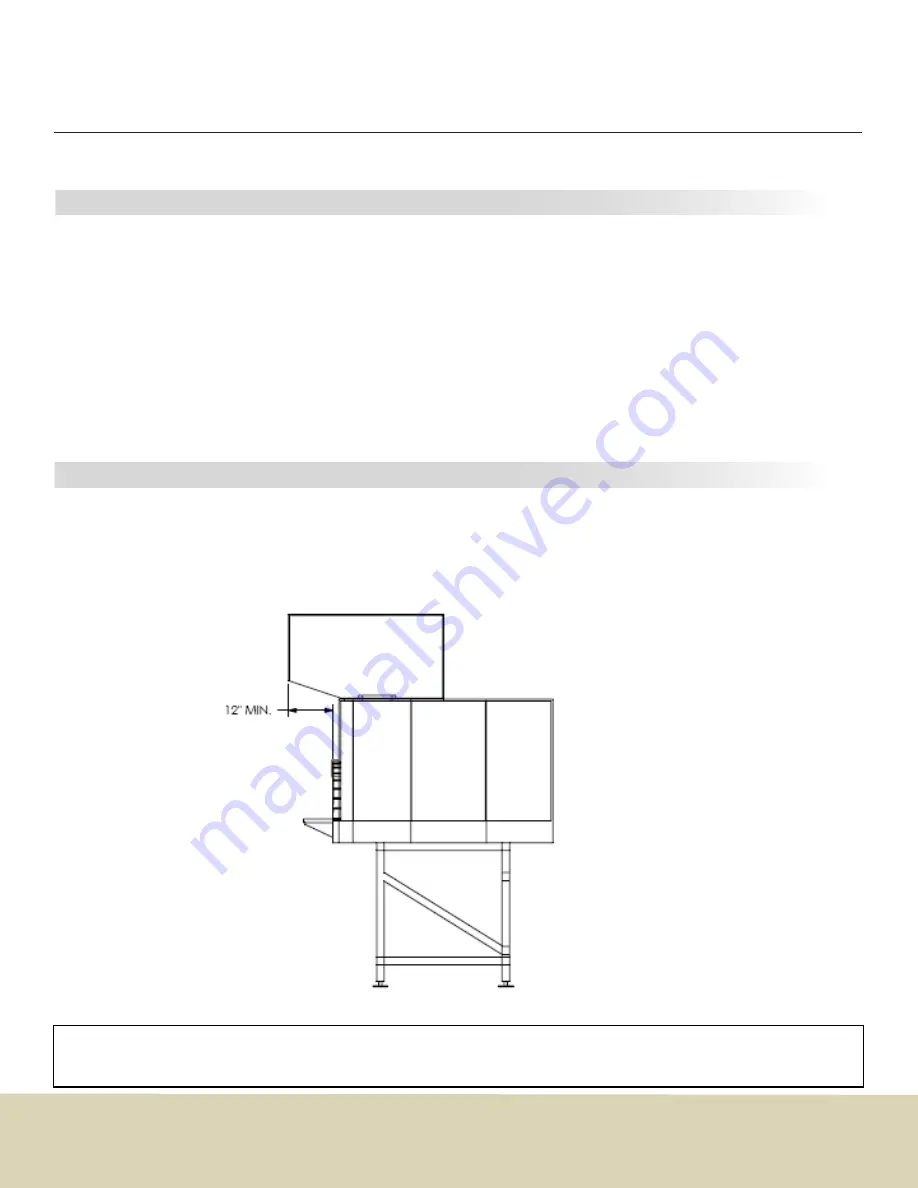

The hood shall extend 12” beyond the front of the oven opening (arch/mouth) and extend 6”

beyond the sides of the oven opening. See diagrams on following page.

SEEK OUT A QUALIFIED PROFESSIONAL TO DESIGN AND INSTALL YOUR VENTING

SYSTEM. CHECK WITH LOCAL AUTHORITIES FOR SPECIFIC CODE REQUIREMENTS

Type 1 Hood Placement