6 | 16

M0701.docx |

Rev 1.5 | Modified on 26/03/2021

| © Remote Control Technologies Pty Ltd

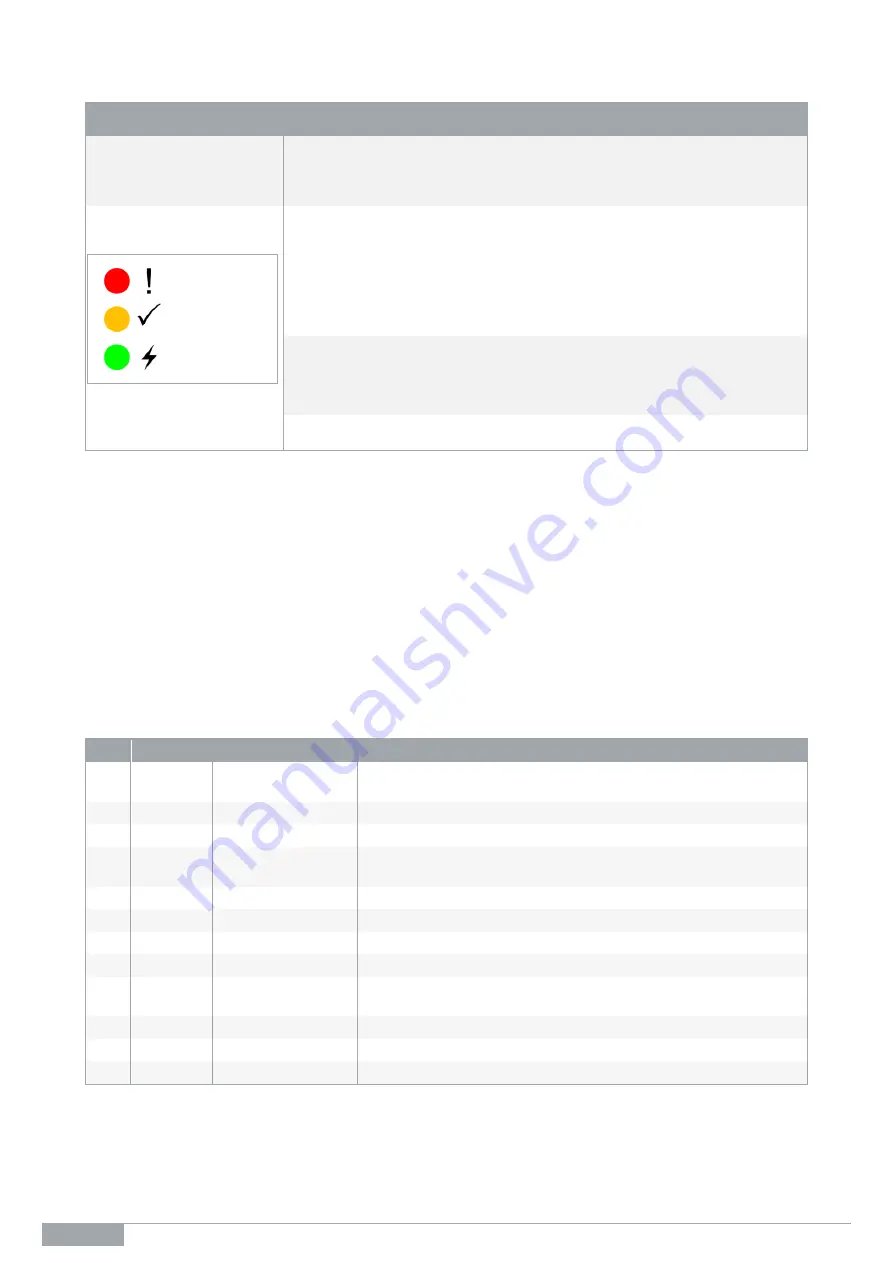

CONTROL UNIT STATUS INDICATOR OPERATION

STATE

INDICATOR SEQUENCE

Battery Power-up

■

All indicators will turn on.

■

All indicators will turn off.

■

After power-up, the control unit will revert to normal operation.

Status Indicator in

Operation

RED

– Fault.

■

If outputs have problems, this will turn on.

■

Outputs 1 & 2

– high current outputs: checked for over current.

■

Output 3

– not checked as it is a low side driver.

■

Output 4

– checked for correct output voltage.

■

Temperature

– checked for board temperature exceeding 80 °C.

YELLOW

– Pulses during normal operation, indicates system OK.

■

Flashes on and off at one-second intervals (on for one second, off for

one second).

GREEN

– On for normal operation.

INSTALLATION INSTRUCTIONS

1.

Mount the control unit in suitable location.

2.

Refer to the wiring table below and the wiring diagram in this manual to connect the control unit.

It is recommended that the wiring is installed alongside the OEM wiring ensuring that it is secured at regular

intervals; this will provide protection from heat and abrasion, and any other excess damage that may occur

with extended vehicle operation. When securing the wiring to the OEM wiring, ensure that the loom is away

from moving vehicle parts which could lead to loom damage.

3.

Mount the LED on the instrument panel in the cabin clear view of the operator.

WIRING CONNECTIONS

NO.

COLOUR

FUNCTIONS

DESCRIPTION

1

Red

Ignition Input

Keyed override switch (11386 kit only). Connect to the ignition

supply at the key switch (ensure it is circuit breaker protected).

2

Black

Ground

Earth

3

Green

Output 1

Flashing LED +ve (13 A)

4

-

Output 3

Optional output (solid). Please that wires must be added to the

supplied loom if you wish to use this output.

5

-

Input 1

Not used

6

Blue

Input 3

Left door switch input

7

Blue

Input 4

Right door switch input (11387 kit join BU wire to BK wire - earth)

8

Grey

Input 2

Park brake switch input

9

-

Output 4

Optional output (flashing). Please that wires must be added to the

supplied loom if you wish to use this output.

10

White

Output 2

OEM horn +ve (13 A)

11

-

Battery Supply

–ve Not used

12

-

Battery ve Not used

Note

: Manufacturer recommends that the Pin 10 Output - (white) be connected to the OEM horn circuit via a

relay if the current draw is greater than 13 amps.

Alarm Indication

System Status

Power Indication

Summary of Contents for 11377

Page 1: ...PRODUCT MANUAL PARK BRAKE WARNING SYSTEM 12 24 VOLTS Part No 11377 11386 11387 ...

Page 14: ...14 16 M0701 docx Rev 1 5 Modified on 26 03 2021 Remote Control Technologies Pty Ltd NOTES ...

Page 15: ...M0701 docx Rev 1 5 Modified on 26 03 2021 Remote Control Technologies Pty Ltd 15 16 NOTES ...