10 | 16

M0030.docx | Rev 1.8 | Modified on 14/06/2019 | © Remote Control Technologies Pty Ltd

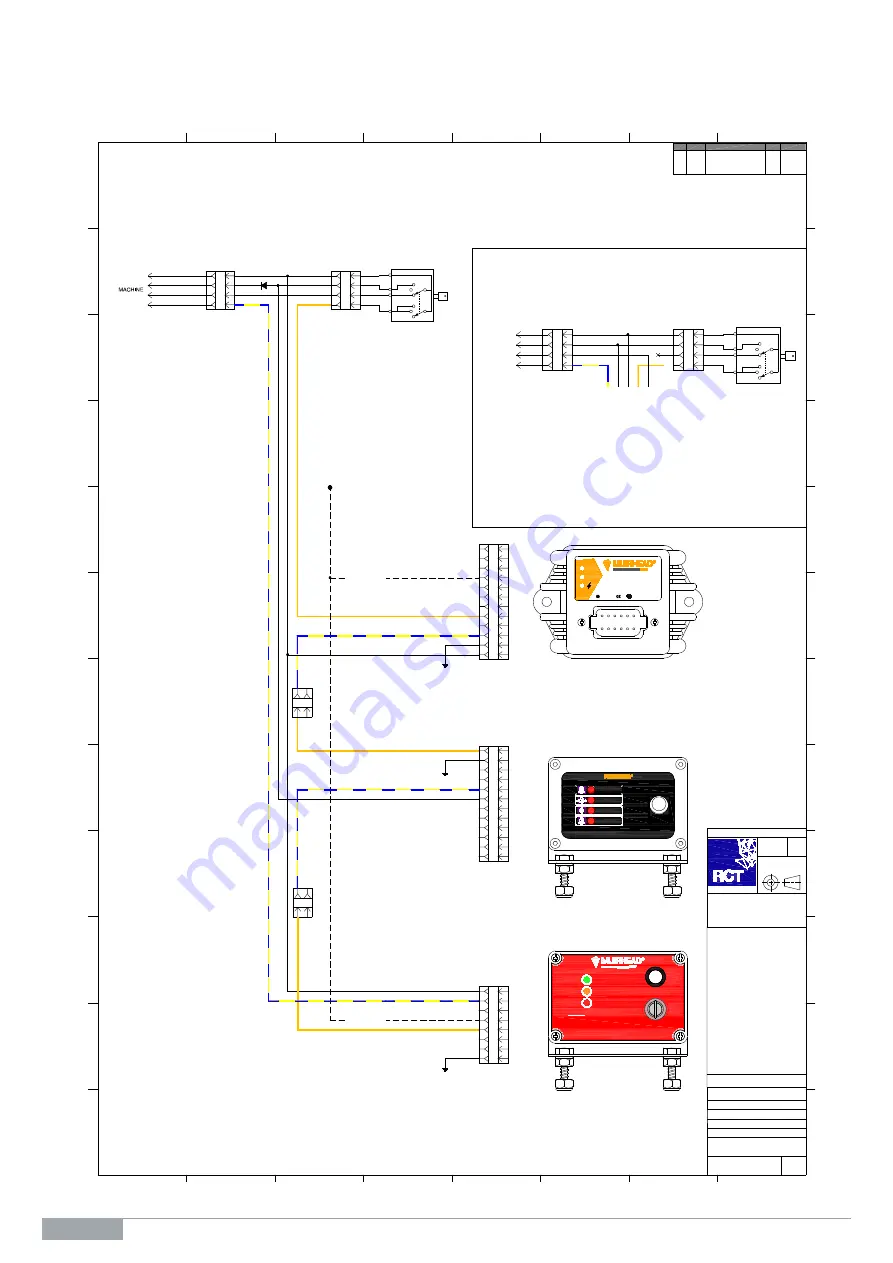

ETR External Wiring Diagram (478i)

If the control unit is installed on a machine that has an EPS control unit or if an 11450 idle timer control unit is

already installed, then follow the ETR circuit wiring as specified below:

Figure 3 Drawing 478i – ETR external wiring diagram

RD-4

OR-4

PU-4

BK-4

BK-4

YL/BU-4

PU-4

OR-4

EPS

(3565)(3747)

(9200)(9301)

FIRE CONTROL

(5884)

1

2

3

4

5

6

7

8

9

10

11

12

AUX CONTROL

1

2

1

2

OR-4

YL/BU-4

OR

BR

PU

YL

1

2

3

4

1

2

3

4

YL/BU-4

R

C

S

B

PU-4

PU-4

RD-4

RD-4

IDLE TIMER CONTROLLER

(11450)

1

2

3

4

5

6

7

8

9

10

11

12

IDLE TIMER

11450

AUX CONTROL

PU-4

YL/BU-4

OR-4

RD-4

BK-4

1

2

3

4

5

6

7

8

!

www.rct.net.au

N12596

1 SHOT O'RIDE

SHUTDOWN

BYPASS

POWER ON /

CYLINDER PRESSURE OK

SYSTEM FAULT /

CYLINDER PRESSURE LOW

SYSTEM DISCHARGE /

ENGINE SHUTDOWN

WARNING

WHEN FIRE UNIT IS ACTIVATED

SIREN WILL OPERATE AND ENGINE WILL

SHUT DOWN AFTER TIME DELAY

PANEL

TEST

FIRE STATUS PANEL

SYSTEM

TEST

WARNING

Machine may return to idle

or shutdown on fault

PROTECTION SYSTEMS

COOLANT LEVEL

OIL PRESSURE

ENGINE TEMP

OIL LEVEL

AUX OUTPUT

SEE NOTE 1

OR-4

YL/BU-4

OR

BR

PU

YL

T

O M

A

CHI

NE

1

2

3

4

1

2

3

4

R

C

S

B

PU-4

RD-4

RD-4

8

7

6

5

4

3

2

1

A

B

C

D

E

F

G

H

I

J

K

L

A

B

C

D

E

F

G

H

I

J

K

L

8

7

6

5

4

3

2

1

A4

COPYRIGHT - ALL RIGHTS RESERVED

This drawing is the property of REMOTE

CONTROL TECHNOLOGIES PTY LTD (RCT),

and is not to be copied or used in whole or in

part for any purpose without the express

authority of RCT. The drawing is to be returned

to RCT, on demand.

ENERGISED TO RUN

(ETR) IDLE TIMER

(11450)/EPS/FIRE

CONTROLLER

CIRCUIT TO SUIT

CATERPILLAR

MACHINES

EXTERNAL WIRING

www.rct.net.au

UNCONTROLLED DOCUMENT

REV

1

DWG No

478i

STATUS

NTS

SCALE

Released

SHEET

1 of 1

BY

EY

DRN

CW

DATE 21/05/13

APPD DAS

DATE 21/05/13

STOCK

CODE

----

PART

NO

----

3rd ANGLE

PROJECTION

ALL DIMENSIONS IN MILLIMETERS

NOTE 1. FOR OFF HIGHWAY TRUCKS (OHT) AND OTHER MACHINES

THAT USE THE C TERMINAL OF THE IGNITION SWITCH;

ENSURE THAT BOTH "AUX CONTROL" WIRES FROM THE

CONTROLLERS ARE CONNECTED AS SHOWN. NOTE THAT THE

C TERMINAL IS DISCONNECTED FROM THE KEY SWITCH

WHEN AUX CONTROL WIRE IS USED AS SHOWN BELOW.

NOTE 2. WHERE THE YELLOW / BLUE AND ORANGE WIRES JOIN,

USE A 2 PIN DEUTSCH PLUG TO MAKE THIS CONNECTION.

NOTE 3. THE IGNITION SWITCH CONNECTIONS ARE MADE BY USING

DEUTSCH PLUGS TO INTERFACE DIRECTLY INTO THE

CATERPILLAR IGNITION SWITCH CONNECTOR PLUG.

NOTE 4. THE IDLE TIMER, EPS AND FIRE CONTROLLER MUST BE

CONNECTED IN THE ORDER AS SHOWN, TO FACILITATE

CORRECT SHUTDOWN PRIORITY SEQUENCE.

NOTE 5. A DIODE IS INSTALLED AS INDICATED WHEN AN EPS

SYSTEM IS INSTALLED.

THE FIRE CONTROLLER RED WIRE CAN BE CONNECTED TO THE

ORANGE WIRE OF THE PRESSURE SWITCH TERMINAL TO AVOID THE

FIRE CONTROLLER TIMING OUT AFTER SIX (6) SECONDS WHEN THE

IGNITION IS SWITCHED OFF.

REV ZONE

DESCRIPTION

BY

DATE

1

L1-J7,

H5

Reordered wires,

removed glands and

wiring from EPS and

replaced 7650 with 5884,

MT

16/12/14