IHL_UDARA_2016_11_04_BEGB

15

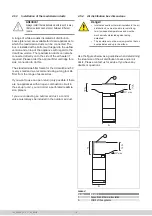

4.2.4

Concentric systems (C12/C32)

The

fl

ue gas outlet (FGO) pipe is surrounded by the

combustion air supply (CAS) pipe with regard to a

concentric

fl

ue gas outlet system. Multicalor carries a

full range of concentric pipes.

The Y-pipe supplied with the

fl

ue gas outlet terminal

must be positioned on top of the appliance with regard

to a concentric connection.

Always position a measuring point in the concentric

piping, by preference, immediately after the Y-pipe or,

if this is not possible, as close as possible to the

appliance.

L

L1

L2

1

Legend

Number

Meaning

1

Measuring point

The length of the

fl

ue gas outlet plus the equivalent

length of the bends must not exceed the maximum

value speci

fi

ed in item 4.2.7.

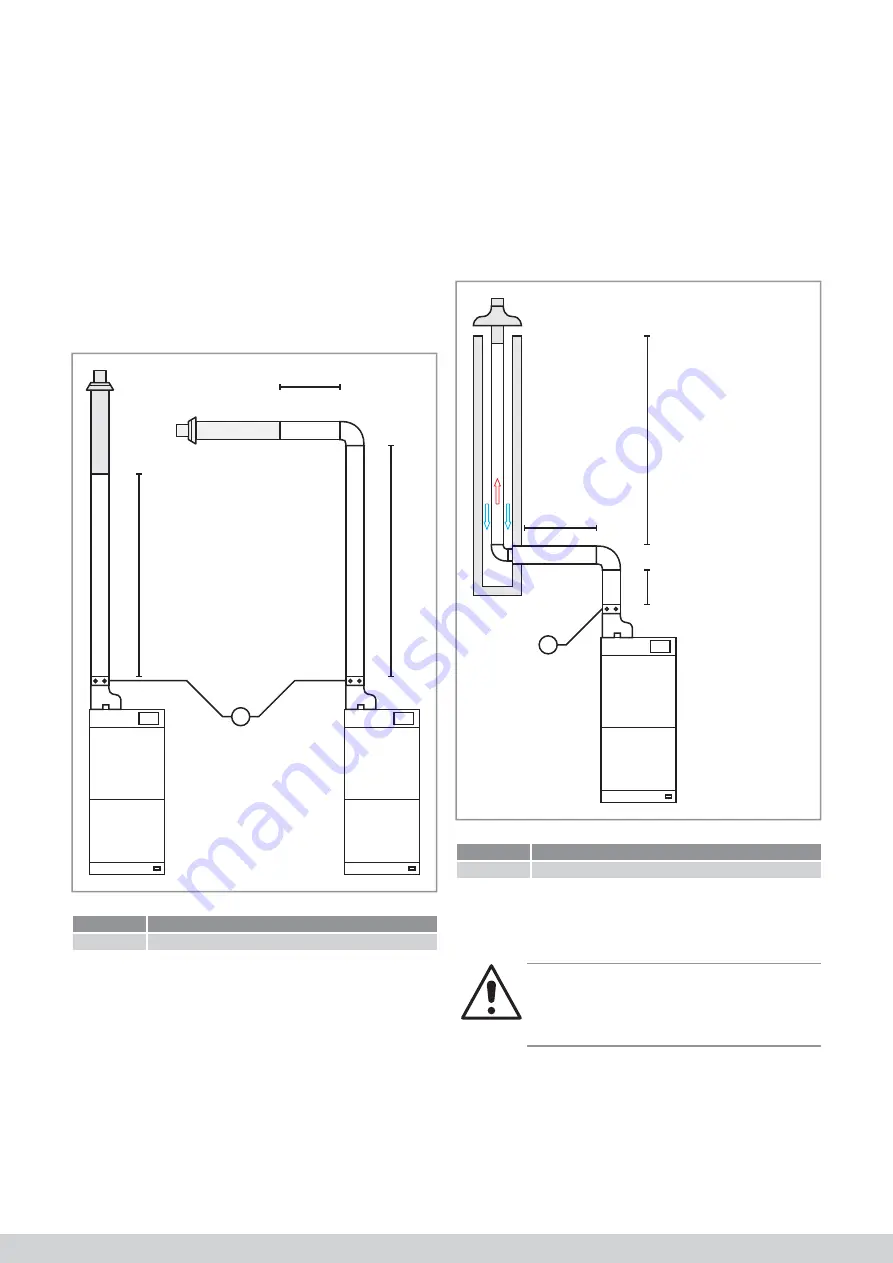

4.2.5

Chimney renovation (C92)

It is sometimes interesting to install a special

fl

exible

fl

ue gas outlet pipe with a diameter of 80 mm in an

existing

fl

ue gas outlet (conventional)

fi

replace. The

combustion air can then be supplied through the air

cavity between the

fl

ue gas outlet pipe and the existing

chimney or in the room itself. The connection between

the

fl

exible pipe in the old

fl

ue gas duct and the

appliance can then take place in parallel or

concentrically.

L1

L3

L2

1

Legend

Number

Meaning

1

Measuring point

The length of the

fl

ue gas outlet plus the equivalent

length of the bends must not exceed the maximum

value speci

fi

ed in item 4.2.7.

Warning!

Do not use the old fl ues as combustion air supply if

they have been used in the past as the FGO for fuel

oil appliances, coal or wood burners or fi replaces.

If you want to use this system, the existing

fi

replace

must at least measure 150 mm x 150 mm when using

a discharge pipe with a diameter of 80 mm.