IHL_UDARA_2016_11_04_BEGB

29

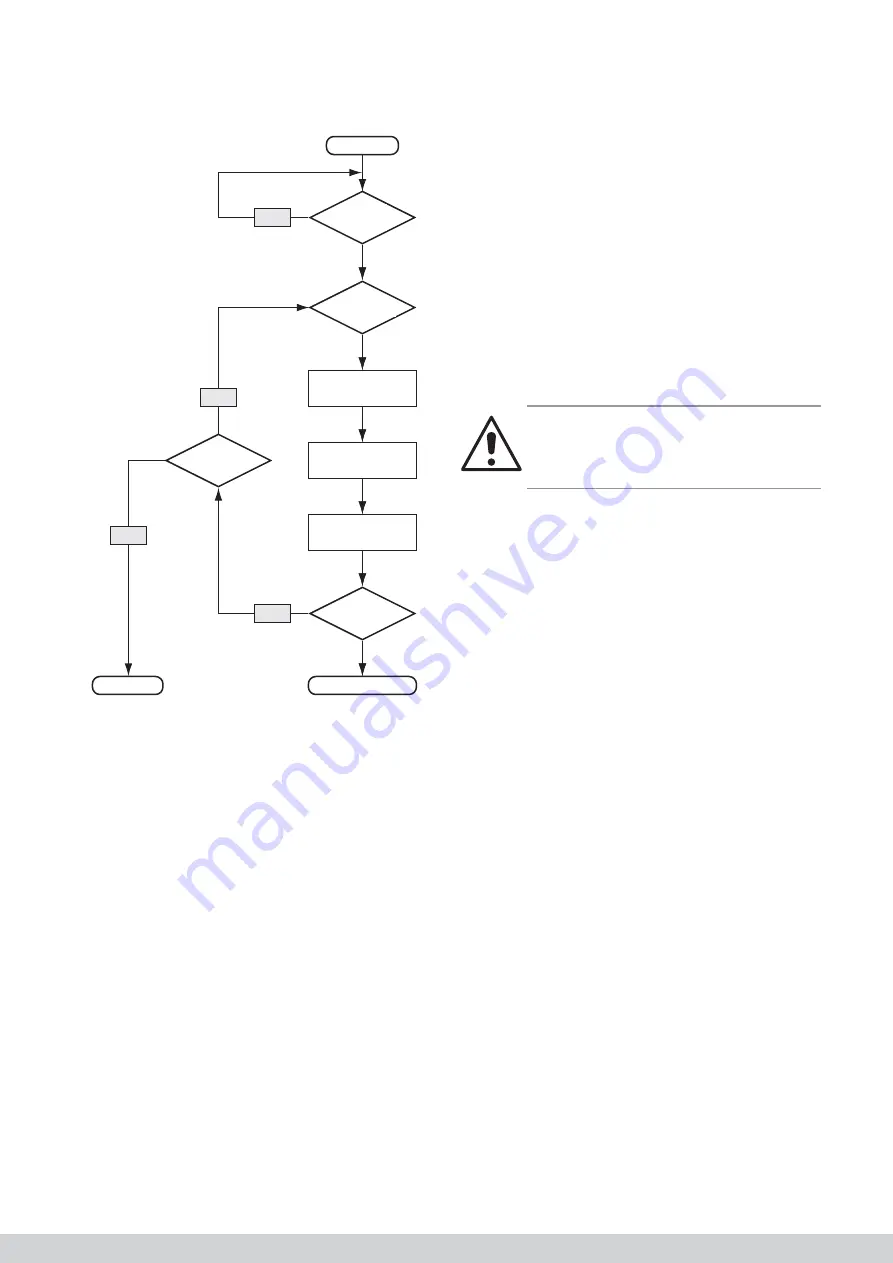

8.1.4 Ignition

fl owchart

Start

Warmte-

vraag?

Zelftest

ok?

Voorspoelen

(t = variabel)

Ontsteking

Gasblok open

Teller

+1

Ionisatie?

Brander aan

LOCKOUT

Teller

< 5?

Ja

Nee

Nee

Nee

8.2 Internal

error

Most “internal” errors are caused by a short-circuit in

the cable loom or because of a faulty burner manage-

ment control system.

Check the wiring in accordance with the

fl

owchart and,

if required, replace the burner management control

system.

8.3

Overheating and NTC errors

1. Check

the

fi

lter for dirt.

2. Check whether suf

fi

cient air vents are open.

3. Check whether the ducts are suf

fi

ciently large.

4. Check the operation of the system fan and the set

air

fl

ow rates. If required, increase the set air

fl

ow

rates or lower the power of the appliance by adjus-

ting parameter TSP 10 in the burner management

control system.

5. Ensure that the appliance can blow without

obstruction (especially with regard to down

fl

ow

appliances).

6. Check the operation of the temperature probes.

The resistance of the probes will be approximately

10 kOhm at room temperature.

7. Check whether the double NTC (discharge air tem-

perature) has not been exchanged with the single

NTC (intake temperature).

8. Check the settings of the temperature protection

by comparing the set parameters with the table in

the manual.

9. Check the cabling of the NTCs to the burner

management control system.

8.4

Display does not work

1. Check the power supply.

2. Check the connection of the control unit with the

display.

3. Check the fuses on the interface printed circuit

board system fan display.

4. Check

the

fl

at cable between the interface printed

circuit board and the display.

Warning!

Pay attention to the correct connection of the fl at

cable. If you press this incorrectly into the connec-

tor, the display can be irreparably damaged.

8.5

Flue gas fan operates continuously or

not at all

Check the control cable (X23), if the PWM signal to

the fan has been interrupted, the

fl

ue gas fan runs

at high speed. If the control cable is OK, the burner

management control system or the

fl

ue gas fan will

probably be faulty.

If the

fl

ue gas fan is not working despite the heat

demand, check the cabling and check whether the

appliance is not locked. Measure the voltage that must

at least be 230 V ± 10%. Replace the

fl

ue gas fan or

burner management control system if required.

8.6

System fan operates continuously or

not at all

If the fan is operational continuously, check whether

the fan position is set to OFF. If this is not the case, it

is normal that the fan is operational.

If the fan is not operational despite the fact that a

percentage speed is being displayed on the display,

fi

rst check the power supply voltage of the fan. If this is

OK, check whether the fan can turn freely.

8.7

No communication with thermostat

Check the cabling. This must, by preference, be a

shielded and twisted cable with a maximum length of

20 m for the RC21.

Yes

Yes

No

No

Ingnition

Injection gas

Ingnition ?

Burner ON

Compteur

< 5?

Teller

+ 1

Request

?

Succesfull

calibration ?

Rinse

t=variable