Basket Fan

INS00131-A

Original instructions

ENGLISH (US) | 7

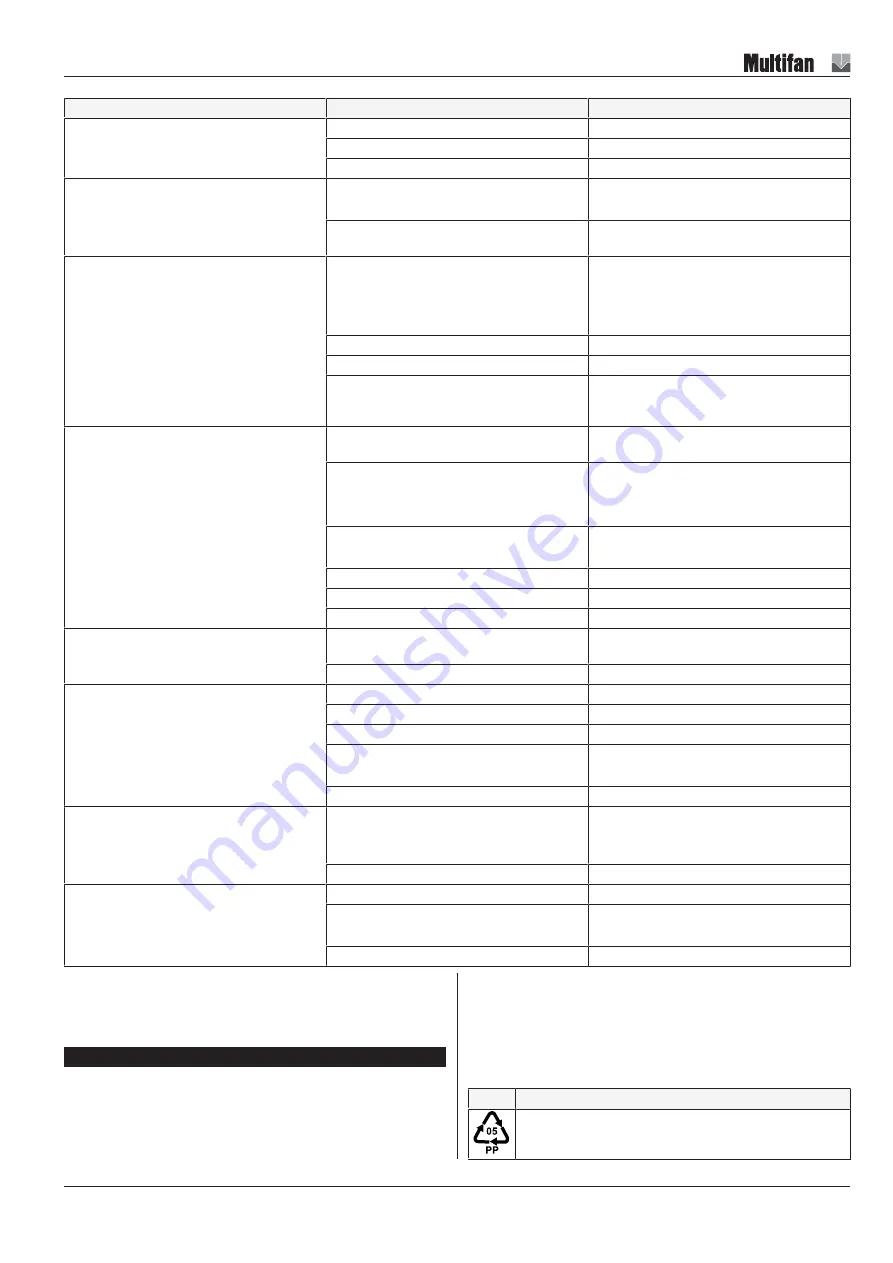

Fault

Possible cause

Possible remedy

Excessive vibration

Impeller imbalance -> impeller damaged

Replace the impeller

Impeller imbalance -> impeller dirty

Clean the impeller

Bearings are damaged or worn

Replace the bearings

Fan does not start

No power supplied to fan

Check all power supplies

Check fuse/circuit breaker

(If present) VFD (Variable Frequency Drive) defec-

tive

Check VFD (refer to VFD manufacturers’ instruc-

tions)

Fan does not start

(supply voltage at fan motor terminals is present)

Thermal protection activated

(Fan motor has overheated)

Clean the motor

Check for overloading of fan system (intake or ex-

haust blocked?)

Check if the supply voltage is not too high or too low

Impeller blocked

Remove the blockage

Only for 1~ fan motors: wrong or defective capacitor Replace the capacitor

Temperature too low for the bearing grease

Do not operate the fan outside the ambient tempera-

ture range as specified on the rating plate and tech-

nical data sheet

Fan motor overheats while running

Fan is overloaded

Check for overloading of the fan system (intake or

exhaust blocked?)

Fan motor overheated due to dirt in cooling fins.

Clean the motor

Supply voltage too high or too low

Check the power supply

Incorrect supply frequency

Check the power supply

Only for 3~ motors: phase voltage imbalance

Check the power supply

Only for 1~ motors: wrong or defective capacitor

Replace the capacitor

Fan rotates in wrong direction

1~ fan motors: capacitor incorrectly connected

Connect according to wiring diagram (contact sup-

plier)

3~ fan motors: supply incorrectly connected

Swap any 2 of the 3 phases of the supply

Fan speed (rpm) is too low

Supply voltage is too low

Check the power supply

Incorrect supply frequency

Check the power supply

Only for 1~ fans: wrong or defective capacitor

Replace the capacitor

Only for 3~ fans: STAR instead of DELTA con-

nected

Connect as DELTA

Check wiring diagram!

3~ fan motors: Phase failure

Restore all 3 phases

High power consumption

Fan is overloaded

Check for overloading of the fan system (intake or

exhaust blocked?)

Fan speed is too high

Check the supply voltage and frequency

Unusual or excessive noises

Impeller hits fan housing

Check the installation and fixings and alignment

Fan is operating in stall point

Lower the system resistance

(Intake or exhaust blocked)

Bearings are damaged or worn

Replace the bearings

Detailed repair and replacement instructions are available from your supplier

or Vostermans Ventilation B.V.

It is highly recommended to use genuine parts only for service and repairs.

9

End of life

Disposal

At the end of the life of this fan, dispose of it properly in accordance with

regulations that apply in your area.

Recycling

The main materials used in the electric motor are copper, steel and

aluminium.

Most of the fan parts have the recycling symbol with material code listed on

them to facilitate proper recycling. Some parts are made of easy to identify

materials such as steel, and have no recycling symbol on them.

Symbol Material

Polypropylene