2. INSTALLATION

MECHANICAL

2-1

2.1.1

DESCRIPTION

The SR469 is packaged in the standard Multilin SR series arrangement, which consists of a drawout unit and a companion fixed case.

The case provides mechanical protection to the unit, and is used to make permanent connections to all external equipment. The only

electrical components mounted in the case are those required to connect the unit to the external wiring. Connections in the case are

fitted with mechanisms required to allow the safe removal of the relay unit from an energized panel, such as automatic CT shorting. The

unit is mechanically held in the case by pins on the locking handle, which cannot be fully lowered to the locked position until the electri-

cal connections are completely mated. Any SR469 can be installed in any SR469 case, except for custom manufactured units that are

clearly identified as such on both case and unit, and are equipped with an index pin keying mechanism to prevent incorrect pairings.

No special ventilation requirements need to be observed during the installation of the unit, but it can be cleaned with a damp cloth.

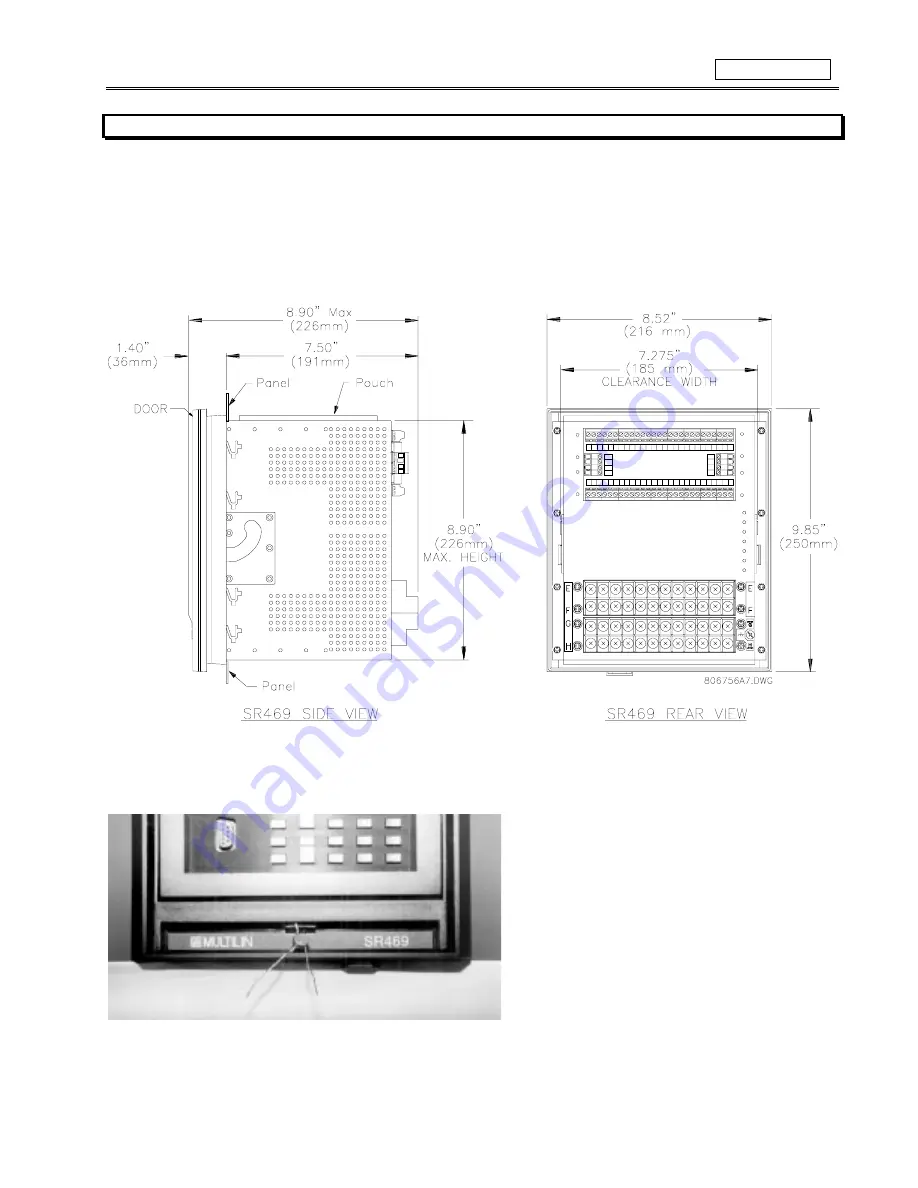

Figure 2-1 SR469 DIMENSIONS

Figure 2-2 SEAL ON DRAWOUT UNIT

To prevent unauthorized removal of the drawout unit,

a wire lead seal can be installed in the slot provided

on the handle as shown in Figure 2-2. With this seal

in place, the drawout unit cannot be removed. A

passcode or setpoint access jumper can be used to

prevent entry of setpoints but still allow monitoring of

actual values. If access to the front panel controls

must be restricted, a separate seal can be installed

on the outside of the cover to prevent it from being

opened.

** WARNING ** Hazard may result if the product is not used for its intended purpose.

2. INSTALLATION

2.1 MECHANICAL

Summary of Contents for SR469

Page 7: ......

Page 19: ...2 INSTALLATION MECHANICAL 2 5 2 1 5 TERMINAL LOCATIONS Figure 2 11 TERMINAL LAYOUT...

Page 21: ...2 INSTALLATION ELECTRICAL 2 7 Figure 2 12 TYPICAL WIRING DIAGRAM...

Page 32: ...ELECTRICAL 2 INSTALLATION 2 18 2 2 14 TYPICAL 2 SPEED MOTOR WIRING...

Page 39: ...OVERVIEW 3 SR469 OPERATION 3 6 yy SETPOINTS yy S1 SR469 SETUP...

Page 104: ...4 SETPOINT PROGRAMMING S11 MONITORING 4 65 Figure 4 24 TRIP COIL SUPERVISION...

Page 113: ...S12 ANALOG I O 4 SETPOINT PROGRAMMING 4 74...

Page 244: ...8 469PC PROGRAM WAVEFORM CAPTURE 8 13 Figure 8 11 WAVEFORM CAPTURE...