2. INSTALLATION

ELECTRICAL

2-13

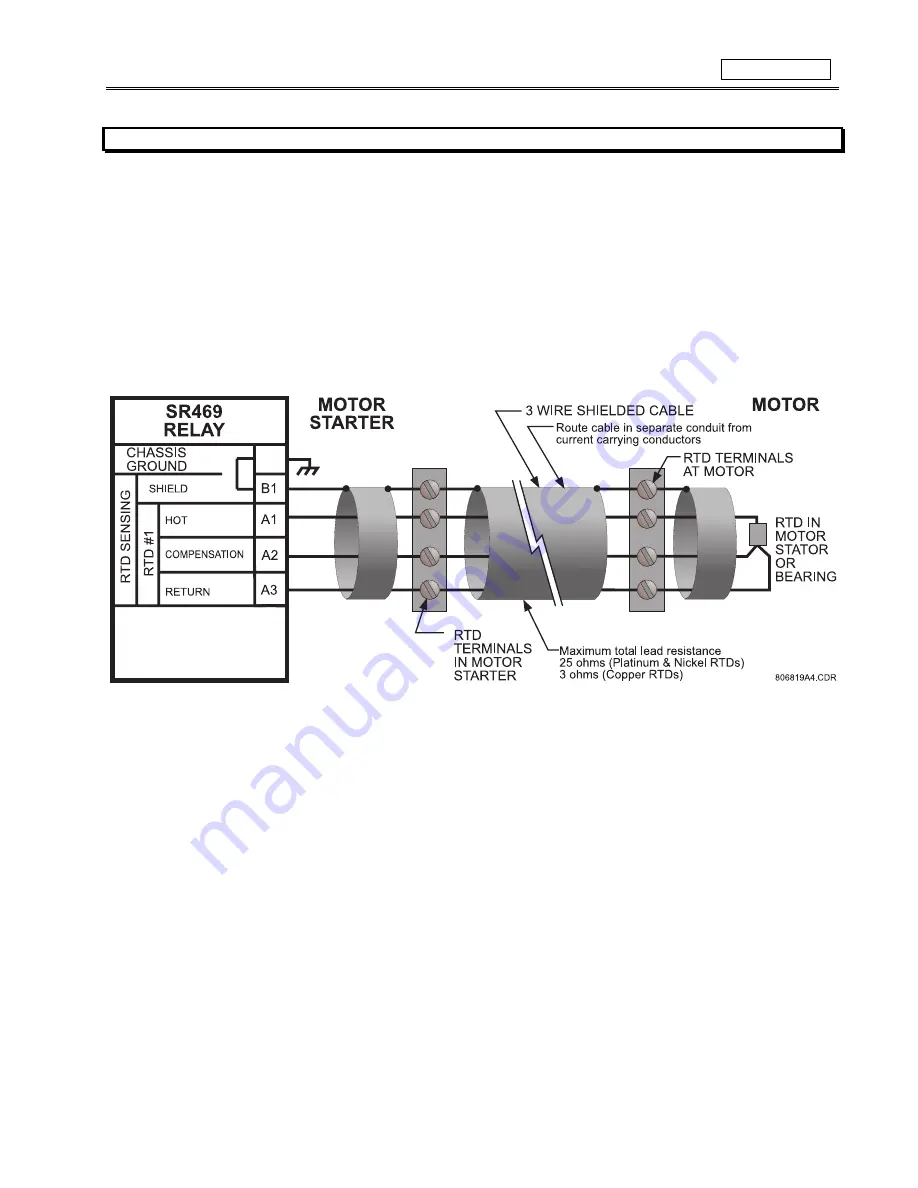

2.2.10

RTD SENSOR CONNECTIONS

The SR469 can monitor up to 12 RTD inputs for Stator, Bearing, Ambient, or Other temperature monitoring. The type of each RTD is field

programmable as: 100

Ω

Platinum (DIN.43760), 100

Ω

Nickel, 120

Ω

Nickel, or 10

Ω

Copper. RTDs must be three wire type. Every two

RTDs shares a common return.

The SR469 RTD circuitry compensates for lead resistance, provided that each of the three leads is the same length. Lead resistance

should not exceed 25

Ω

per lead for platinum and nickel type RTDs or 3

Ω

per lead for Copper type RTDs. Shielded cable should be used

to prevent noise pickup in the industrial environment. RTD cables should be kept close to grounded metal casings and avoid areas of

high electromagnetic or radio interference. RTD leads should not be run adjacent to or in the same conduit as high current carrying

wires.

Figure 2-21 RTD WIRING

IMPORTANT: The RTD circuitry is isolated as a group with the Analog Input circuitry and the Analog Output circuitry. Only one ground

reference should be used for the three circuits. Transorbs limit this isolation to

±

36 volts with respect to the SR469 safety ground.

Summary of Contents for SR469

Page 7: ......

Page 19: ...2 INSTALLATION MECHANICAL 2 5 2 1 5 TERMINAL LOCATIONS Figure 2 11 TERMINAL LAYOUT...

Page 21: ...2 INSTALLATION ELECTRICAL 2 7 Figure 2 12 TYPICAL WIRING DIAGRAM...

Page 32: ...ELECTRICAL 2 INSTALLATION 2 18 2 2 14 TYPICAL 2 SPEED MOTOR WIRING...

Page 39: ...OVERVIEW 3 SR469 OPERATION 3 6 yy SETPOINTS yy S1 SR469 SETUP...

Page 104: ...4 SETPOINT PROGRAMMING S11 MONITORING 4 65 Figure 4 24 TRIP COIL SUPERVISION...

Page 113: ...S12 ANALOG I O 4 SETPOINT PROGRAMMING 4 74...

Page 244: ...8 469PC PROGRAM WAVEFORM CAPTURE 8 13 Figure 8 11 WAVEFORM CAPTURE...