www.modellmarkt24.ch

17

through the integral hinge! Move the panels to and fro repeatedly

to ease the hinge. Glue the top spar caps

11.2

in both tail panels.

Fig. 11

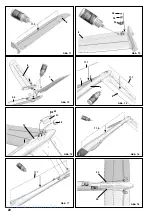

10. Installing the control surface horns

Assemble the swivel horns as shown in

Fig. 12

, and glue them

in the appropriate recesses in the tail control surfaces. Note that

the horn holes should face the servo, so that they line up correctly

with the hinge pivot axis.

11. Installing the tail panels

The tail panels

7 + 8

have to be glued to each other in the centre

and to the fuselage tail fairing

14

. Take care here: all the joints

should be neat, accurate and without gaps. The bottom spar

caps

11.1

can now be fitted, as shown in

Fig. 14

.

12. The ballast chamber

“Adequately powered” electric gliders often require tail ballast.

We have a neat solution in our resealable ballast chamber cover

41

, which is secured using the screw

34

.

13. Additional fuselage reinforcements

Glue the bottom fuselage longeron

11.6

to the underside of the

fuselage.

Fig. 16

Glue the top fuselage longeron

11.7

to the top of the fuselage.

Fig. 17

14. V-tail control surface linkages

If you have installed a pair of servos for elevator and rudder

control, you will need to use the two pre-formed pushrods

30

.

Set the servos to centre from the transmitter, and connect the

pre-formed end of the pushrods to the output arms. Shorten the

wire pushrods if necessary, slip the ends through the swivel

connector barrels, and fit the grubscrews to secure them.

Fig. 18

2

nd

variant - elevator only. In this case the wire pushrods

29

are

required: they are installed as shown in

Fig. 19

.

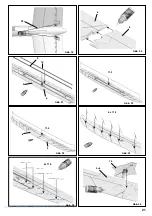

15. Preparing the wings

The first step here is to glue the wing panels

5 + 6

together in the

centre as shown. Ensure that they line up exactly. Any error at this

point will seriously affect the model’s flying characteristics.

Fig. 20

The following preparatory work is necessary before you install

the rectangular carbon fibre wing spars

9 + 10

:

Lay out all the parts where you can reach them easily - the wing,

the spars, adhesive, a cloth - and clear away everything else

which could get in the way.

Since the spars are a very close fit in the wings, they displace

most of the adhesive when pressed into the recess; this causes

the glue to set very quickly. If you make a mistake at this point,

you may not be able to press the spars into position before the

glue sets.

Caution: the spars lie below the wing surface over part of

their length (dihedral). The exposed slots are covered later by

the stickers 16.

This procedure is crucial, and that is why we describe it very

carefully below. Please note that we will not replace spoiled

parts which result from using the wrong procedure!

a. Trial-fit the spars, i.e. press them into their slots ‘dry’ (without

glue).

b. Apply the adhesive (e.g. Elapor cyano) only to the bottom of the

spar slot in the wing.

c. Lay the wing down flat.

d. In one swift process, press the spar into the spar slot as far as

it will go.

e. Immediately wipe off excess glue where it is squeezed out of

the channel.

f. If necessary, flex the wing away from the spar slightly, across

the chord, and apply more glue.

Fig. 21

16. Additional wing reinforcements

The bottom spar cap

11.3

can now be glued to the underside of

the wing: lay the wing down flat with the curved tips extending

over the ends of the workbench before installing it.

Fig. 22

Now turn the wing over and glue the top spar cap

11.4

in the spar

slot. It is a good idea to curve the spars beforehand where they

fit in the wingtip area.

Fig. 23

Twenty diagonal braces

11.9

have to be glued to the top and

bottom of the wing in a ‘herringbone’ pattern; this is a special

measure designed to increase the torsional rigidity of the wing.

Please take great care over this procedure, and in particular

glue each brace to the top and bottom wing spars

11.4 + 11.3

.

The diagonal braces are easier to install if you curve them to the

approximate shape beforehand.

Figs. 24 + 25

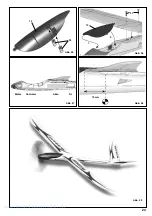

Completing the wing

17. Wing centre section doubler

Sand off the pimples on the central area of the wing where the

centre section doubler

15

fits, and glue the doubler in place

using cyano.

Fig. 26

18. Installing the aileron servos and the M6 socket

Temporarily place the servos in their recesses. Cut the servo

leads to the correct length and position them in the wing together

with the green M6 socket, as shown in

Fig. 27

.

Caution: check the wire assignment carefully; the insulation

colours on the plug and socket must match up correctly.

Back to the soldering iron!

Carefully separate the servo ribbon cable into its individual

colours using a pair of side-cutters. Strip a little insulation from

the wire ends, and tin (apply solder to) the bare conductors. Tin

the individual contacts of the M6 socket. Slip a piece of heat-

shrink sleeve over each wire, and solder the wire ends to the

contacts in the arrangement shown in

Fig. 27

.

Slip the sleeves over the soldered joints and shrink them in

place using a heat-gun or similar.

Press the servos into their wells, and secure them with a drop of

cyano at each mounting lug. Deploy the servo leads in the servo

lead ducts, pressing them into place with a blunt, flat instrument.

Place the connector in the holder and glue it in place as shown.

Ensure in particular that not the tiniest trace of adhesive gets

onto the surfaces which later come into contact with the

mating half of the connector, i.e. apply the glue to the socket

holder only.

19. Concealing the wing spars

Part of the main spar lies below the surface of the underside of

the wing; these channels can be covered by applying the stickers

16

. The stickers improve the look of the model, and compensate

for the stepped height of the surface.

Fig. 28

20. Aileron linkages

Assemble the aileron horns from parts

24, 25

and

26

, as shown

in

Fig. 29

, and carefully glue them in the appropriate recesses in

www.modellmarkt24.ch