page 40 — DCa25Usi 60 hz generaTor • operaTion anD parTs manUal — rev. #3 (07/19/11)

trailer Maintenance

Tires/Wheels/lUg nUTs

Tires and wheels are a very important and critical

components of the trailer. When specifying or replacing the

trailer wheels it is important the wheels, tires, and axle are

properly matched.

Tire Wear/inflation

Tire inflation pressure is the most important factor in tire

life. Pressure should be checked cold before operation

Do

noT bleed air from tires when they are hot!. Check inflation

pressure weekly during use to insure the maximum tire life

and tread wear.

Table 16 (Tire Wear Troubleshooting) will help pinpoint the

causes and solutions of tire wear problems.

CaUTion

alWaYs wear safety glasses when

removing or installing force fitted parts.

Failure to comply may result in serious

injury.

CaUTion

Do noT attempt to repair or modify a

wheel.

Do noT install in inner tube to

correct a leak through the rim. If the rim

is cracked, the air pressure in the inner

tube may cause pieces of the rim to explode (break off)

with great force and cause serious eye or bodily injury.

Table 16. Tire Wear Troubleshooting

Wear pattern

Cause

solution

Center Wear Over inflation.

Adjust pressure to particular

load per tire manufacturer.

Edge Wear

Under inflation.

Adjust pressure to particular

load per tire manufacturer.

Side Wear

Loss of camber

or overloading.

Make sure load does not

exceed axle rating.

Align wheels.

Toe Wear

Incorrect toe-in.

Align wheels.

Cupping

Out-of-balance.

Check bearing adjustment

and balance tires.

Flat Spots

Wheel lockup and

tire skidding.

Avoid sudden stops when

possible and adjust brakes.

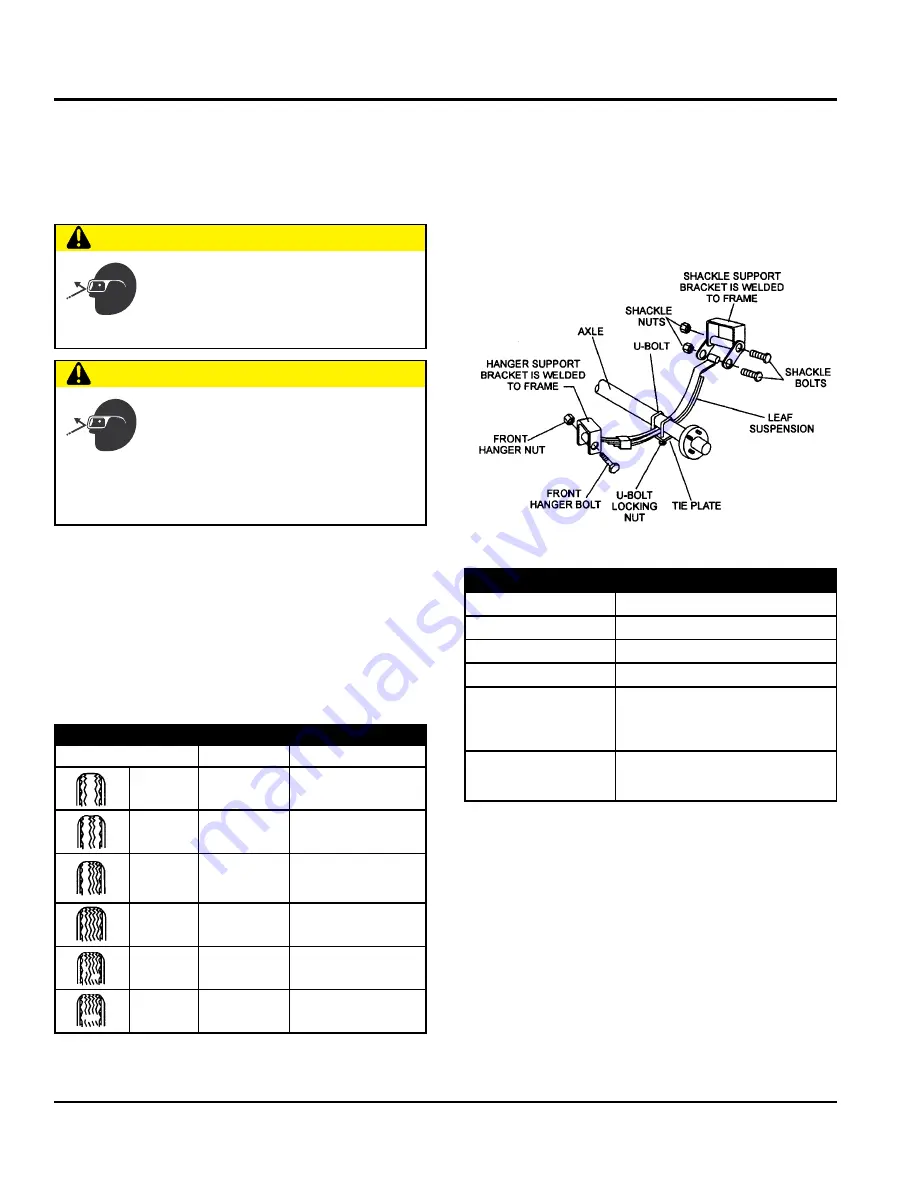

suspension

The

leaf suspension springs and associated components

(Figure 57) should be visually inspected every 6,000 miles

for signs of excessive wear, elongation of bolt holes, and

loosening of fasteners. Replace all damaged parts

(suspension) immediately. Torqued suspension components

as detailed in Table 17.

Figure 57. Major Suspension Components

Table 17. suspension Torque requirements

item

Torque (Ft.-lbs.)

3/8" U-Bolt

Min-30 Max-35

7/16" U-Bolt

Min-45 Max-60

1/2" U-Bolt

Min-45 Max-60

Shackle Bolt

Spring Eye Bolt

Snug fit only. Parts must rotate freely.

Locking nuts or cotter pins are

provided to retain nut-bolt assembly.

Shoulder Type

Shackle Bolt

Min-30 Max-50

Summary of Contents for DCA5USI

Page 47: ...DCA25usi 60 hz Generator operation and parts manual rev 3 07 19 11 page 47 notes...

Page 50: ...page 50 DCA25Usi 60 hz Generator operation and parts manual rev 3 07 19 11 GENERATOR ASSY...

Page 52: ...page 52 DCA25Usi 60 hz Generator operation and parts manual rev 3 07 19 11 control box ASSY...

Page 54: ...page 54 DCA25Usi 60 hz Generator operation and parts manual rev 3 07 19 11 control box ASSY...

Page 62: ...page 62 DCA25Usi 60 hz Generator operation and parts manual rev 3 07 19 11 BATTERY ASSY...

Page 64: ...page 64 DCA25Usi 60 hz Generator operation and parts manual rev 3 07 19 11 Muffler Assy...

Page 66: ...page 66 DCA25Usi 60 hz Generator operation and parts manual rev 3 07 19 11 FUEL TANK ASSY...

Page 68: ...page 68 DCA25Usi 60 hz Generator operation and parts manual rev 3 07 19 11 ENCLOSURE ASSY...

Page 74: ...page 74 DCA25Usi 60 hz Generator operation and parts manual rev 3 07 19 11 RUBBER SEALS ASSY...

Page 79: ...DCA25usi 60 hz Generator operation and parts manual rev 3 07 19 11 page 79 notes...