PAGE 32 — JTNSW20-24HTCSL SERIES RIDE-ON TROWEL • OPERATION MANUAL — REV. #1 (3/24/16)

MAINTENANCE

If, after making Blade Pitch adjustments the machine is

still finishing poorly, blades, trowel arms, and trowel arm

bushings may be suspect and should be looked at for

adjustment, wear, or damage. See the following sections.

Changing Blades

It is recommended that ALL the blades on the entire

machine are changed at the same time. If only one or

some of the blades are changed, the machine will not

finish concrete consistently and the machine may wobble

or bounce.

1. Place the machine on a flat, level surface. Adjust

the blade pitch control to make the blades as flat as

possible. Note the blade orientation on the trowel arm.

This is important for ride-on trowels as the two sets

of blades counter-rotate. Lift the machine up, placing

blocks under the main guard ring to support it.

2. Remove the bolts and lock washers on the trowel arm,

and then remove the blade.

3. Scrape all concrete and debris from the trowel arm.

This is important to properly seat the new blade.

4. Install the new blade, maintaining the proper orientation

for direction of rotation.

5. Reinstall the bolts and lock washers.

6. Repeat steps 2-5 for all remaining blades.

Clean-Up

Never allow concrete to harden on the power trowel.

Immediately after use wash any concrete off the trowel

with water, be careful not to spray a hot engine or muffler.

An old paint brush or broom may help loosen any concrete

that has started to harden.

Trowel Arm Adjustment Procedure

A level, clean area to test the trowel prior to and after

adjustment is essential. Any unlevel spots in the floor

or debris under the trowel blades will give an incorrect

perception of adjustment. Ideally, a 5' x 5' three-quarter

inch thick flat steel plate should be used for testing.

1. To determine which blades need adjustment, place the

trowel in the test area (three-quarter inch thick plate)

and look for the following conditions:

• Pitch the blades as flat as possible and look at the

adjustment bolts. They should all barely make contact

with the lower wear plate on the spider. If you can

see that one of them is not making contact, some

adjustment will be necessary.

• Is the machine wearing out blades unevenly (i.e. one

blade is completely worn out while the others look

new)?

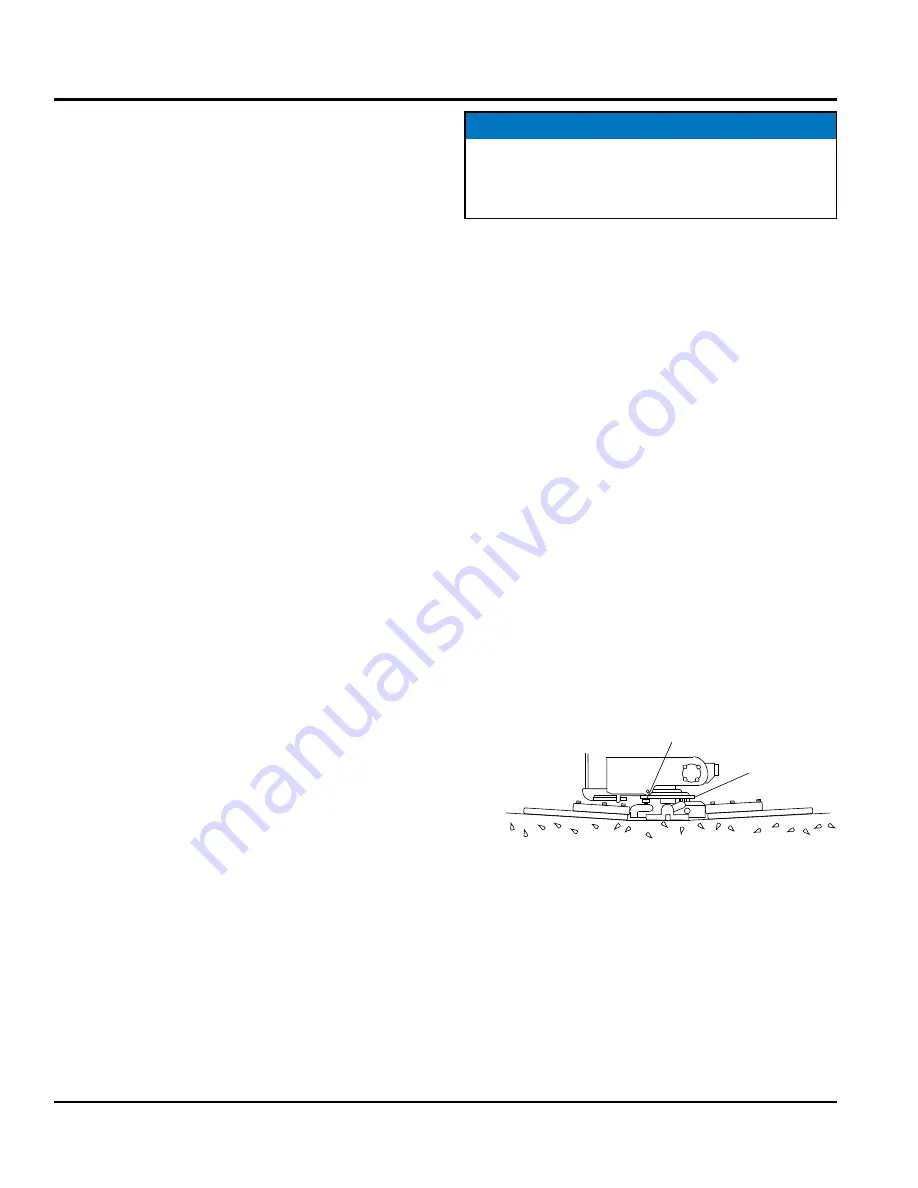

Figure 30 illustrates "worn spider bushings or bent trowel

arms". Check to see that adjustment bolt is barely touching

(0.10" max. clearance) lower wear plate. All alignment

bolts should be spaced the same distance from the lower

wear plate.

Figure 30. Worn Arm Bushings

NOTICE

The following procedure should be followed to adjust

trowel arms when it becomes apparent that the trowel

is finishing poorly or in need of routine maintenance.

SURFACE

LOWER

WEAR

PLATE

“DISHED” EFFECT ON

FINISHED CONCRETE

ADJUSTMENT

BOLT

INCORRECT

ALIGNMENT