SG1400/1600C4F STUDIO GENERATOR • OPERATION MANUAL — REV. #0 (07/22/20) — PAGE 39

MAINTENANCE

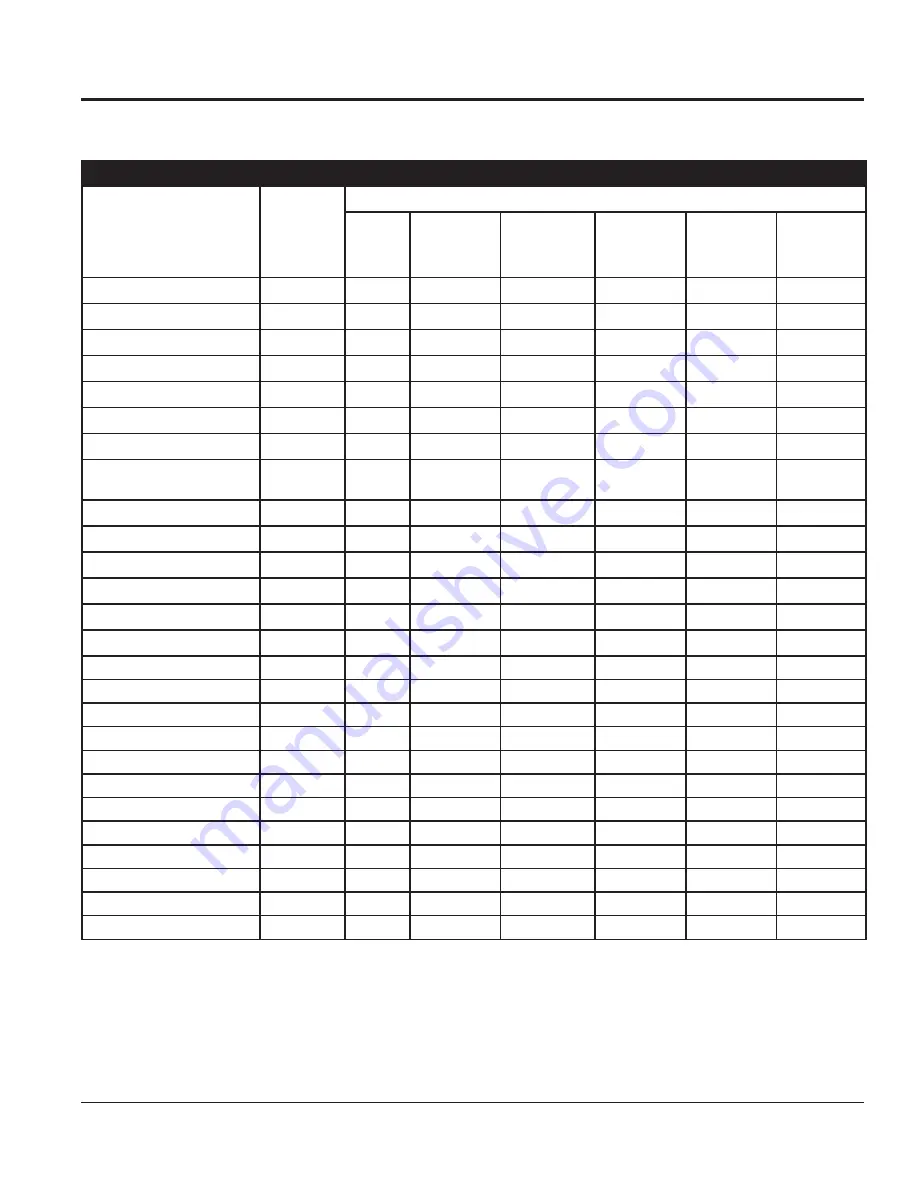

Use Table 18 as a general maintenance guideline when servicing your engine. For more detail engine maintenance

information, refer to the engine owner’s manual supplied with your engine.

Table 18. Engine Maintenance Schedule

DESCRIPTION

OPERATION

INTERVAL

DAILY

3

250 HOURS

OR

3 MONTHS

3

500 HOURS

OR

6 MONTHS

1,2,3

1000 HOURS

OR

1 YEAR

3

2000 HOURS

OR

2 YEARS

2,3

5000 HOURS

OR

4 YEARS

3

Air Intake Piping

Check

X

Engine Lubricating Oil Level

Check

X

Air Tank and Reservoirs

Drain

X

Crankcase and Breather Tube

Inspect

X

Engine Coolant Level

Check

X

Fuel -Water Separator

Drain

X

Air Cleaner Restriction

Check

X

Air Compressor

Mounting Hardware

Check

X

Charge-Air Cooler

Check

X

Charge-Air Piping

Check

X

Radiator Hoses

Check

X

Air Intake Piping

Inspect

X

Fan, Cooling

Check

X

Coolant Level

Check

X

Drive Belts

Check

X

Engine Coolant - Antifreeze

Check

X

Fuel Filter (Spin-On Type)

Replace

X

Lubricating Oil and Filters

Change

X

Radiator Pressure Cap

Check

X

Cooling Fan Belt Tensioner

Check

X

Fan Hub, Belt-Driven

Check

X

Air Compressor Discharge Line

Check

X

Cooling System

Drain

X

Vibration Damper, Rubber

Check

X

Vibration Damper, Viscous

Check

X

Overhead Set

Adjust

X

1. T

he lubricating oil and lubricating oil filter interval can be adjusted based on application, fuel consumption, gross vehicle

weight, and idle time.

2.

Antifreeze check interval is every oil change or 500 hours or 6 months, whichever occurs first. The operator must use heavy-

duty, year-round antifreeze that meets the chemical composition of ASTM D6210. The antifreeze change interval is 2 years

or 2000 hours whichever occurs first. Antifreeze is essential for freeze, overheat, and corrosion protection.

3.

Follow the manufacturer’s recommended maintenance procedures for the starter, alternator, generator, batteries, electrical

components, exhaust brake, charge air cooler, radiator, air compressor, air cleaner, refrigerant compressor, and fan clutch.