DCA-150SSJU3— OPERATION AND PARTS MANUAL — REV. #0 (11/14/07) — PAGE 33

1

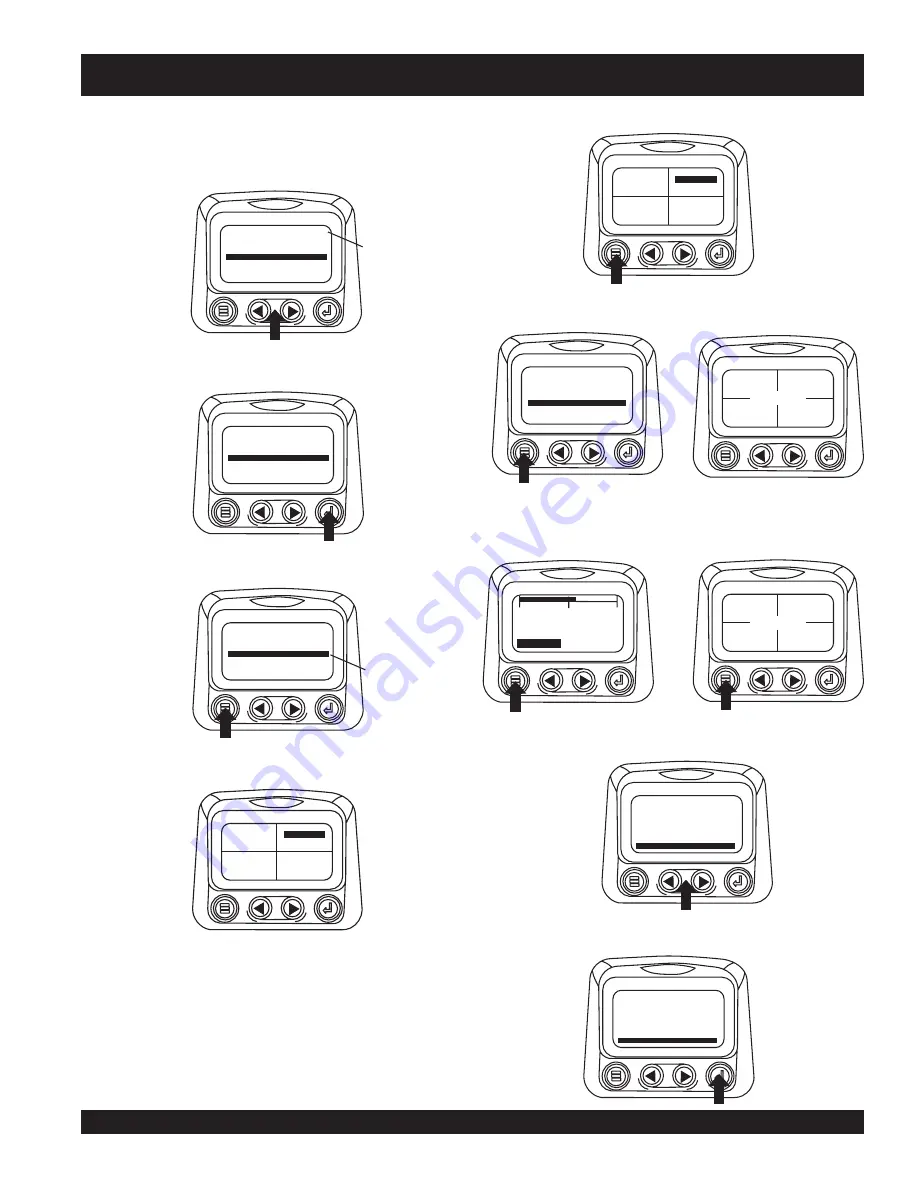

9.

The parameter that is highlighted is the selected

parameter for the screen. Use the “Arrow Buttons” to

highlight the new parameter to be placed in the quadrant

selected in the previous screen.

10. Touch the “Enter Button” to change the selected

parameter in the quadrant to the new parameter.

11. Use the “Menu Button” to return to the “4-Up Custom

Setup” screen.

12. The parameter in the selected quadrant has changed

to the parameter selected in the previous screen.

13. Repeat the parameter selection process until all spaces

are filled.

14. Touch the “Menu Button” to return to the main menu.

15. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

Utilities

(information and troubleshooting)

1. Starting at the single or four engine parameter display,

touch the “Menu Button”.

2. The main menu will be displayed. Use the “Arrow Buttons”

to scroll through the menu until the “Utilities” is

highlighted.

3. Once the “Utilities” menu item has been highlighted, touch

the “Enter Button” to activate the “Utilities” functions.

ENGINE SPEED

ENGINE COOLANT TEMPERATURE

BATTERY POTENTIAL

ENGINE OIL PRESSURE

ENGINE HOURS

ENGINE OIL TEMPERATURE

3

1

4

2

The number to the right

of the parameter indicates

the quadrant in which it

is displayed.

1= Upper Left Quadrant

2 = Lower Left Quadrant

3 = Upper Right Quadrant

4 = Lower Right Quadrant

ENGINE SPEED

ENGINE COOLANT TEMPERATURE

BATTERY POTENTIAL

ENGINE OIL PRESSURE

ENGINE HOURS

ENGINE OIL TEMPERATURE

3

1

2

4

ENGINE SPEED

ENGINE COOLANT TEMPERATURE

BATTERY POTENTIAL

ENGINE OIL PRESSURE

ENGINE HOURS

ENGINE OIL TEMPERATURE

3

1

4

2

Note the number to

the right of the selected

parameter indicating that the

parameter is now assigned

to that display location

125°F

COOL TEMP

143°F

OIL TEMP

57 PSI

1000 RPM

ENG RPM

OIL PRES

125°F

COOL TEMP

143°F

OIL TEMP

57 PSI

1000 RPM

ENG RPM

OIL PRES

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

ADJUST BACKLIGHT

SETUP 1-UP DISPLAY

SELECT UNITS

SETUP-4-UP DISPLAY

125°F

COOL TEMP

143°F

OIL TEMP

57 PSI

1000 RPM

ENG RPM

OIL PRES

COOL

1800 RPM

0

1500

3000

TEMP

ENG RPM

125°F

COOL TEMP

143°F

OIL TEMP

57 PSI

1000 RPM

ENG RPM

OIL PRES

ENGINE CONF

SETUP-4-UP DISPLAY

SELECT UNITS

STORED CODES

G

SETUP 1-UP DISPLAY

ADJUST BACKLIGHT

UTILITIES

ENGINE CONF

SETUP-4-UP DISPLAY

SELECT UNITS

STORED CODES

G

SETUP 1-UP DISPLAY

ADJUST BACKLIGHT

UTILITIES

DCA-150SSJU3 — DIAGNOSTIC DISPLAY