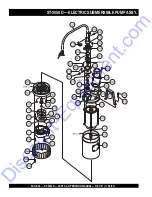

PAGE 22 — ST-3050D — PARTS & OPERATION MANUAL — REV. #1 (11/18/02)

ST-3050D SUB. PUMP/CTRL. BOX — INSTALLATION (MCP102/104)

DANGER:

Remember this control box contains hazardous voltages.

Disconnect all sources of power before installing or servicing.

There exists the possibility of electrocution, electric shock or

burn, which can cause severe bodily harm or even

death

!

Remember the

MCP102 Control Box

is to be used only for

230 VAC 3-phase applications and the

MCP 104 Control Box

is for 460 VAC 3-phase applications. Neither control box has

float switch capability.

POWER CORD REQUIREMENTS

When routing the three phase power via a power cord to the

control box,

ALWAYS

use the correct wire size. Please reference

Table 3 (Cord Length/Wire Size) to determine the correct wire

size. Incorrect wire size can adversely affect the performance of

the pump.

CONTROL BOX MOUNTING

Mount the control box in an

upright vertical position

. Make sure

the control box is securely fastened to a flat surface, that is free

of dust, dirt, moisture or any elements that may contaminate or

erode the electronic components of the control box.

3-PHASE POWER CORD (INPUT TO BOX) INSTALLATION

1.

The three phase

input

power cord should have four wires.

Each wire is color coded. The colors are

RED

,

WHITE

,

BLACK

and

GREEN

.

2.

Remove the 3-phase AC input connector housing from the

control box, then route the three phase input power cable

through the cable gland on the control box. Attach the

wires to the terminal block on the electronic overload unit

inside the control box as indicated by Table 5 and Figure 15.

3.

Tighten the connector housing to ensure a tight fit between

the power cord and the connector body. This will prevent

the cable from pulling out of the terminal block and also

prevent moisture from entering the control box.

It is recommended that the power being supplied to the control

box

ALWAYS

be connected to a

circuit breaker

or a

quick

disconnect

switch. This safety feature allows for quick removal

of power from the control box in the event of an emergen

cy.

4.

Connect the other end of the 3-phase input power cord to

the voltage source. Remember to provide a means of

disconnecting the power from the control box (circuit breaker

or quick disconnect switch). Also make sure to provide a

good earth ground to the control box.

ELECTRONIC OVERLOAD SETTING (230 VAC, 3Ø)

1.

Using a small flat-blade screwdriver, set the

amperage dial pointer on the electronic

overload unit to 14.2 amps.

ELECTRONIC OVERLOAD SETTING (460 VAC, 3Ø)

1.

Using a small flat-blade screwdriver,set the

amperage dial pointer on the electronic

overload unit to 7.1 amps.

3-PHASE POWER INSTALLATION (OUTPUT TO PUMP)

1.

The three phase

output

power cord should have four wires.

Each wire is color coded. The colors are

RED

,

WHITE

,

BLACK

and

GREEN

.

2.

Remove the 3-phase AC output power connector housing

on the control box, then route the three phase output power

cable through the cable gland on the control box. Attach

the wires to the AC terminal blocks on the

electronic

overload

unit as indicated by Table 6 and Figure 15.

14.2

5.1

6.3

7.1

5.1

6.3

Discount-Equipment.com