DCa300SSC / DCa300SSCU gen. • operation anD partS manUal — rev. #1 (08/10/11) — page 33

BatterY

This unit is of negative ground

Do not

connect in reverse.

Always maintain battery fluid level between the specified

marks. Battery life will be shortened, if the fluid level are

not properly maintained. Add only distilled water when

replenishment is necessary.

Do not

over fill. Check to see whether the battery

cables are loose. Poor contact may result in poor starting

or malfunctions.

Always

keep the terminals firmly

tightened. Coating the terminals with an approved battery

terminal treatment compound. Replace battery with only

recommended type battery. The battery type used in this

generator is BCI Group 27.

The battery is sufficiently charged if the specific gravity

of the battery fluid is 1.28 (at 68° F). If the specific gravity

should fall to 1.245 or lower, it indicates that the battery is

dead and needs to be recharged or replaced.

Before charging the battery with an external electric source,

be sure to disconnect the battery cables.

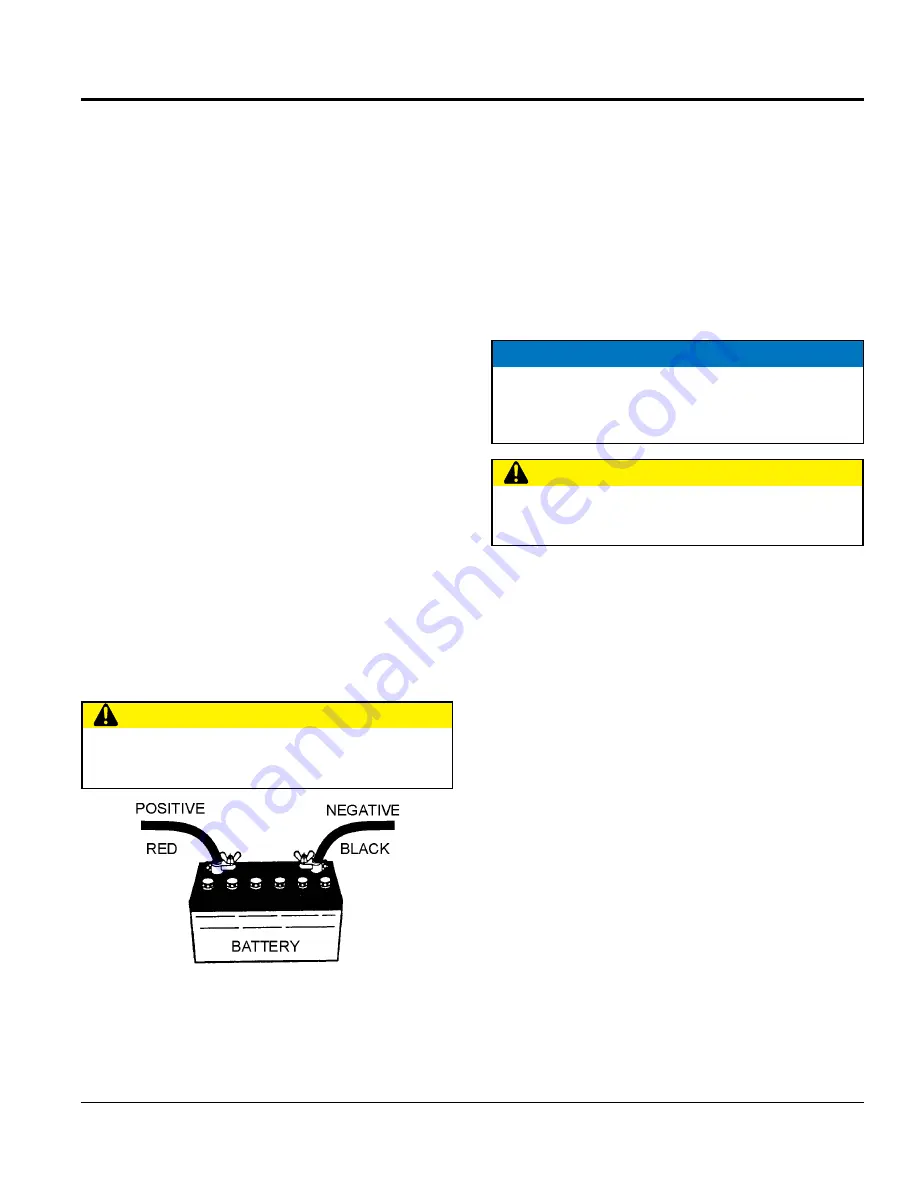

Battery Cable installation

ALWAYS be sure the battery cables (Figure 34) are properly

connected to the battery terminals as shown below. The

red cable

is connected to the positive terminal of the

battery, and the

black cable

is connected to the negative

terminal of the battery.

Figure 34. Battery Connections

CaUtion

alWaYS

disconnect the negative terminal

FirSt

and

reconnect negative terminal

laSt

.

When connecting battery do the following:

1.

never

connect the battery cables to the battery

terminals when the

mpeC Control Switch

is in either

the

manUal

position.

alWaYS

make sure that the

mpeC Control Switch

is in the

oFF/reSet

position

when connecting the battery.

2. Place a small amount of battery terminal treatment

compound around both battery terminals. This will

ensure a good connection and will help prevent

corrosion around the battery terminals.

alternator

The polarity of the alternator is negative grounding type.

When an inverted circuit connection takes place, the

circuit will be in short circuit instantaneously resulting the

alternator failure.

Do not

put water directly on the alternator. Entry of water

into the alternator can cause corrosion and damage the

alternator.

Wiring

Inspect the entire generator for bad or worn electrical wiring

or connections. If any wiring or connections are exposed

(insulation missing) replace wiring immediately.

piping anD HoSe ConneCtion

Inspect all piping, oil hose, and fuel hose connections for

wear and tightness. Tighten all hose clamps and check

hoses for leaks.

If any hose (

fuel or oil

) lines are defective replace them

immediately.

CaUtion

Inadequate battery connections may cause poor

starting of the generator, and create other malfunctions.

NOTICE

If the battery cable is connected incorrectly, electrical

damage to the generator will occur. Pay close attention to

the polarity of the battery when connecting the battery.

inspectiOn/setUp

Summary of Contents for WhisperWatt DCA300SSC

Page 21: ...DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 page 21 Notes ...

Page 49: ...DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 page 49 NOTES ...

Page 53: ...DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 page 53 notes ...

Page 56: ...page 56 DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 GENERATOR ASSY ...

Page 60: ...page 60 DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 control box ASSY ...

Page 78: ...page 78 DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 muffler ASSY ...

Page 84: ...page 84 DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 enclosure ASSY ...

Page 92: ...page 92 DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 RUBBER SEALS ASSY ...

Page 103: ...DCA300SSC DCA300SSCU Gen operation and parts manual rev 1 08 10 11 page 103 notes ...