RANGE FOR CONTROL PARAMETER

Parameter

Range for PT.1 sensor

Range for J, K, PT100

IT

CT

Ct2

Pb2

PB

0.0 to 999.9°C

0.0 to 999.9°C

0 to 9999

0 to 9999

0 to 9999

0 to 9999

4 to 99 sec

4 to 99 sec

1 to 100°C

0.1 to 100.0°C

0.1 to 100.0°C

1 to 100°C

1 to 20 sec

1 to 20 sec

2.0 to 25.0°C

2.0 to 25.0°C

5 to 200 sec

5 to 200 sec

0.0 to 99.59 (mm.ss)

0.0 to 99.59 (mm.ss)

0.0 to 99.59 (mm.ss)

0.0 to 99.59 (mm.ss)

0 to 99 sec

0 to 99 sec

2 to 20°C

2 .0 to 20.0°C

4 to 99 sec

4 to 99 sec

-9.0 to 9.0°C

-9 to 9°C

-20.0 to +20.0°C

-20 to 20°C

DT

MR

OFFSET

HYS1

HYS2

C-PB

C-ON

C-OFF

R1DL

R2DL

ALTM

ERROR

OPEN

SRE

MEANING

When an error has occurred the display indicates error codes

as given below.

Check the sensor and the input wiring. If problem still exists,

replace the sensor. And still if problem is not solved yet by the

user, then please contact company person

Sensor is not connected or

Over range condition or

sensor break

Sensor connection is reversed

ERROR DISPLAY

CORRECTIVE ACTION:

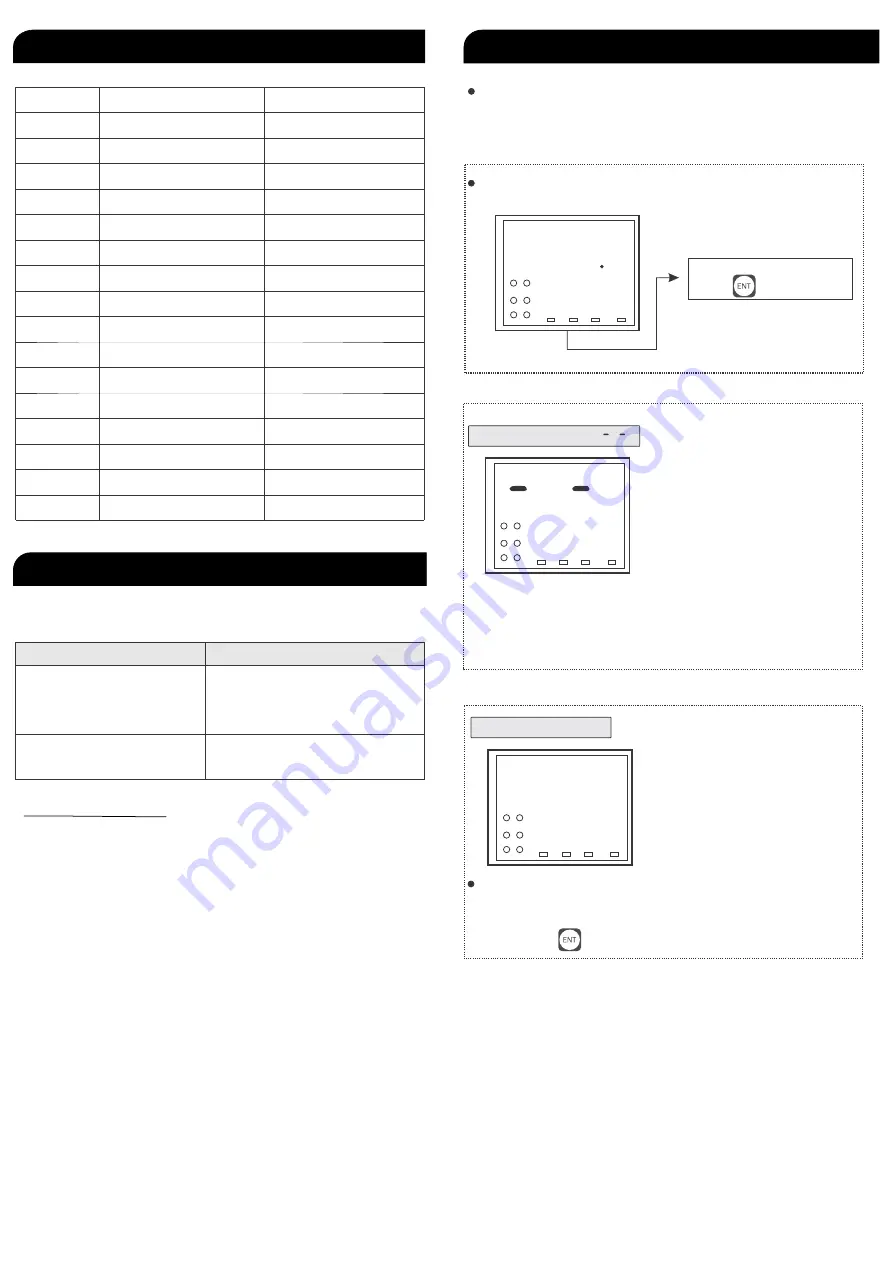

SOAK TIME FUNCTION

Soak feature can be use to hold the process at a preset

temperature for a preset time.

(Range : selectable up to 0 to 999 hour)

When soak time is completed, then display indicate

message as shown below.

2345

END

To restart process

press key for 3 sec.

MEMO

YES

/

NO

YES

: In case of power supply failure, remaining soak time

counting will be continued at next power on.

NO

: In case of power supply failure, soak time counting will

be restarted at next power on.

Soak time memory (

MEMO

)

END

SAVE

/

NO

In case of soak time end, if user apply

SAVE

in

configuration then soak time end (

END

) display will still

indicate after power supply failure. And that will only reset

by pressing key for 3 sec.

Soak time end (

END

)

Page 4