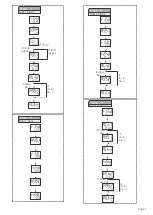

SET POINT SETTING

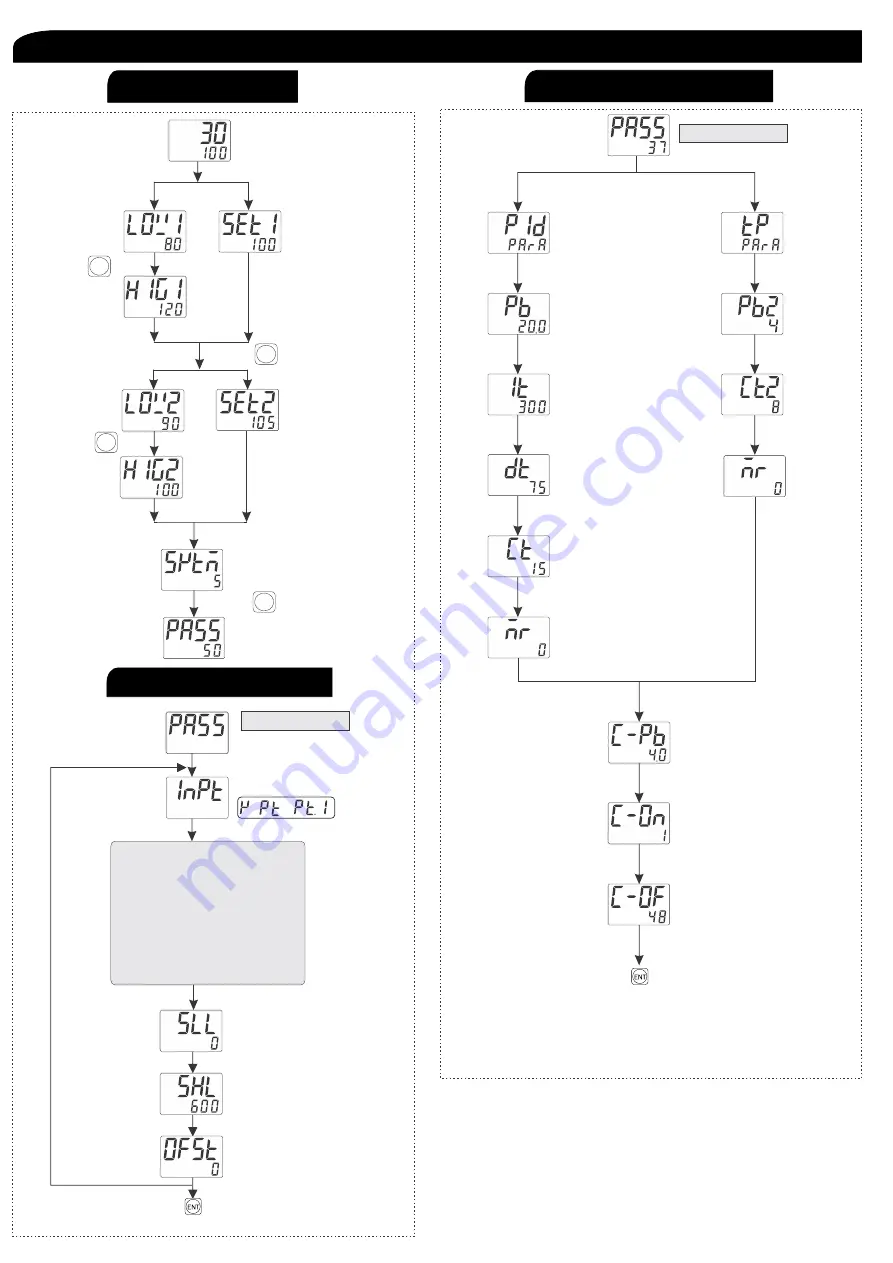

PARAMETER SETTING

PARAMETER SETTING

Presskey

SET

If ALM1=IN-B/AB-O

Presskey

SET

Presskey

SET

If ALM2=IN-B/AB-O

Press key for 4 sec

SET

If Soak = Yes

///

j

73

Case 1: Heat + soak + alarm

Case 3: Heat + cool

Case 2: Heat + Heat

Case 4: Heat + Alarm

Case 5: cool + cool

Case 6: cool + alarm

Case 7: alarm+ alarm

BASIC CONFIGURATION

Password is 73

If CTR1 PID

=

CONTROL PARAMETER SETTING

Press key to Save & Exit

If CTR 2 =BL.TP

If CTR1 TP

=

Password is 37

Press key to Save & Exit

IF

R2MD OFF and

S2MD=INDI

=

/

Page 5