Reviews:

No comments

Related manuals for GRM21BE71C475MA12K

XYR Series

Brand: Zimmer Pages: 16

XYR Series

Brand: Zimmer Pages: 2

AIR CHAMP BD Caliper Brake

Brand: Nexen Pages: 16

SRF-48

Brand: P.A. Pages: 17

GWC Series

Brand: Cooper Pages: 20

Greerco

Brand: Chemineer Pages: 22

ET6100

Brand: Danfoss Pages: 56

50AN

Brand: 3M Pages: 26

Z80-D460.02 K3

Brand: Jäger Pages: 40

CNC Studio USB

Brand: GoCNC Pages: 39

E220-plus

Brand: Covaris Pages: 59

BOXER-8150AI

Brand: Aaeon Pages: 34

ROLLON ELM 110 SP

Brand: Timken Pages: 9

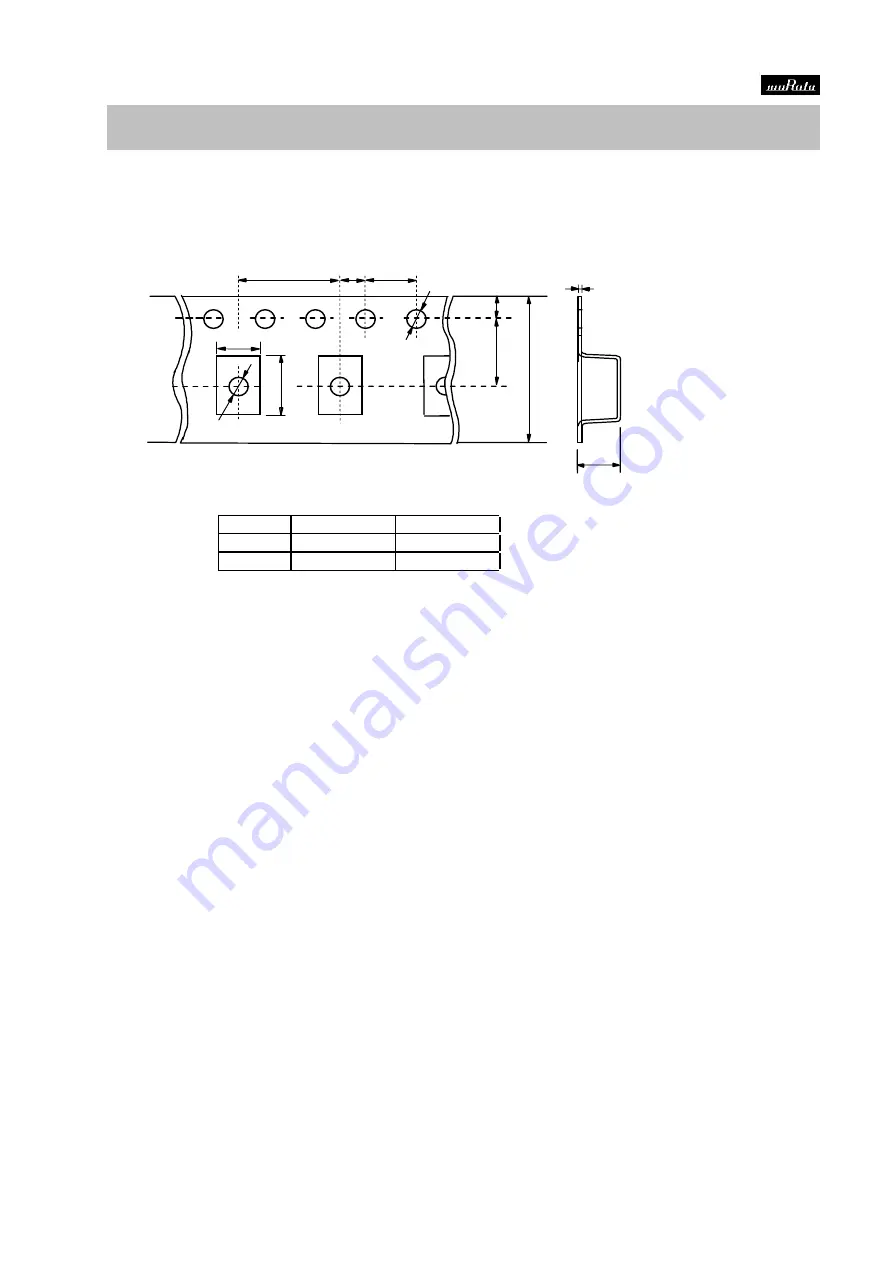

GQM22M5C2H680JB01 Series

Brand: Murata Pages: 25

ZP190 Series

Brand: ABB Pages: 9

PQstorI

Brand: ABB Pages: 36

QB300

Brand: Kitagawa Pages: 62

NZM2-XKSA

Brand: Moeller Pages: 2