MGS Installation and Operation Manual

24

1000-0085 Rev 0

Bump Test

Exposing the sensor to a gas and observing its response to

the gas. The objective is to establish if the sensor is reacting

to the gas and all the sensor outputs are working correctly.

There are two types of bump test.

Quantified:

A known concentration of gas is used.

Non-Quantified:

A gas of unknown concentration is

used.

Calibration

Exposing the sensor to a calibration gas, setting the “zero” or

standby voltage to the span/range, and checking/adjusting all

the outputs, to ensure that they are activated at the specified

gas concentration.

CAUTION:

Before you carry out the test or calibration:

•

Advise occupants, plant operators, and supervisors.

•

Check if the MGS is connected to external systems such as

sprinkler systems, plant shut down, external sirens and

beacons, ventilation, etc. and disconnect as instructed by the

customer.

•

Deactivate alarm delays if selected at JP5, JP6 as per Figure

2 and Figure 3.

•

For bump test or calibration the MGS should be powered up

for 24 hours. The instrument should be fully stabilised per

Section 4.

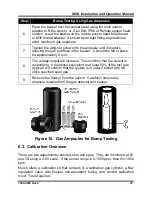

6.2. Bump Testing

After installation, the units should be bump tested. Expose the sensors to

appropriate test gas (NH

3

, CO

2

, etc.). The system will alarm when the test gas

ppm value is above the alarm level. The gas should put the system into alarm

and light the red LED. The delay prevents the audible alarm from sounding

and the relay from switching (if delay is set).

With a bump test you can see the functions of the sensor - the red LED will

light, the relay and audible alarm will function, and the output (0-10V, for

example) will show the gas level.

Ideally bump tests are conducted on site in a clean air atmosphere.