MGS Installation and Operation Manual

1000-0085 Rev 0

25

NOTE:

Prior to carrying out a bump test, check and adjust the

zero setting as described in the Calibration section.

NOTE:

Procedures for bump test and calibration vary depending

on the sensor technology used and the gas in question. The MGS

is available in three sensor versions: Semiconductor (SC),

Electrochemical (EC) and Infrared (IR).

NOTE:

Do not pressurize the sensor.

NOTE:

For semiconductor sensors, you MUST use calibration

gas in a balance of air (

not

N

2

).

IMPORTANT:

After a semiconductor or electrochemical sensor is

exposed to a substantial gas leak, the sensor should be checked

and replaced if necessary.

NOTE:

To test the audible alarm and/or relay function, check the

delay is set at zero and expose to gas. You can mute the audible

alarm by removing jumper 3.

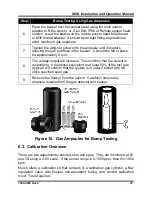

Step

Bump Testing Using Calibration Gas Cylinders

1

Remove the enclosure lid of the

gas detector (not in an exhaust

area).

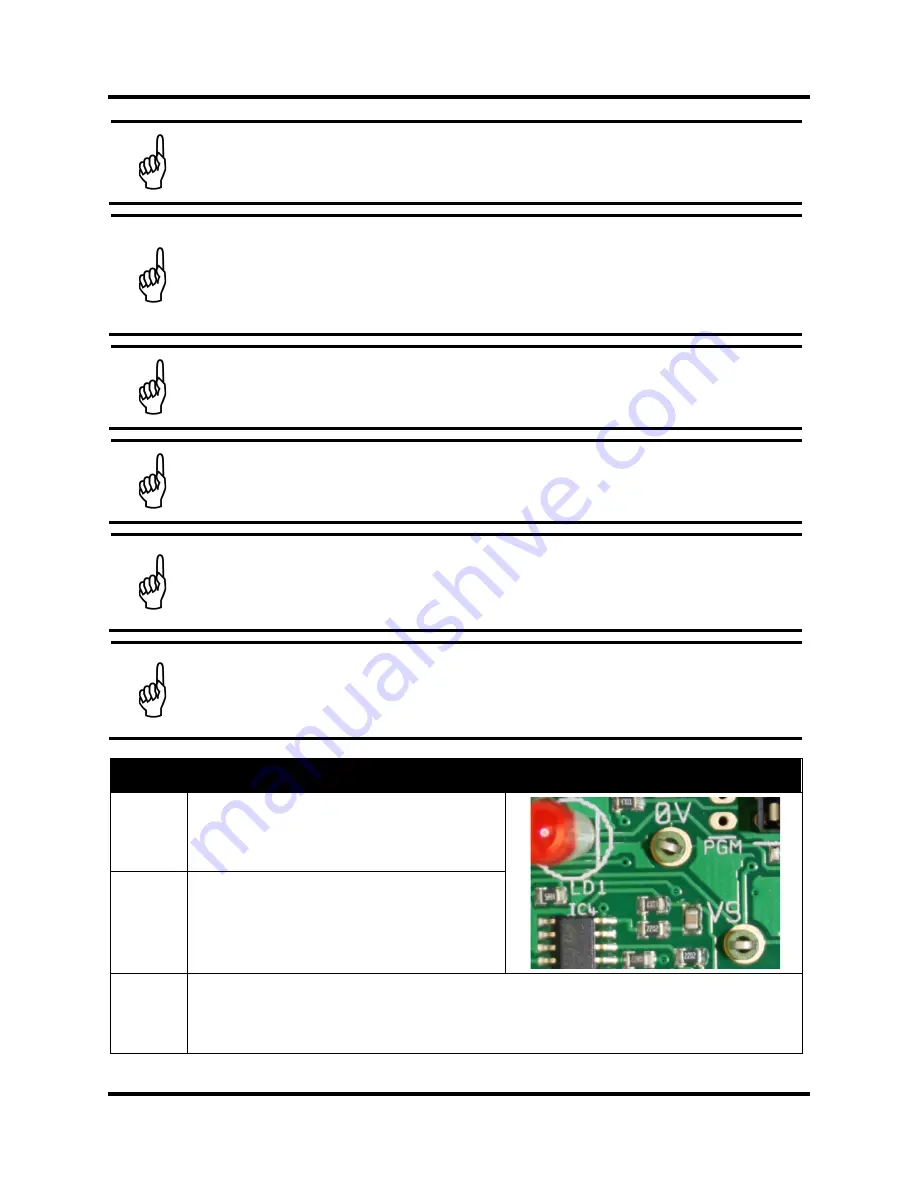

2

Connect a voltmeter to monitor

sensor response (in Volts DC).

Monitor the response between

pins 0V and VS.

3

Expose the sensor to gas from the cylinder. You can place the

entire MGS into a plastic bag or use a plastic hose/hood to direct

gas to the sensor head. A response of above 80% is acceptable.