MGS Installation and Operation Manual

1000-0085 Rev 0

27

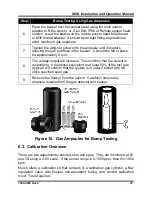

Step

Bump Testing Using Gas Ampoules

6

Place the beaker over the sensor head using the multi sensor

adaptor to fit the sensor, or, if an Exd, IP66 or Remote sensor head

version, screw the beaker on the remote sensor head M42 thread

or M35 thread adaptor. It should be as tight fitting as possible to

allow maximum gas exposure.

7

Tighten the wing-nut screw onto the ampoule until it shatters

allowing the gas to diffuse in the beaker. It should be left in place

for approximately 5 min.

8

The voltage output will increase. This confirms that the sensor is

responding. A response equivalent to at least 50% of the test gas

(typical) will confirm that the system is in order if tested with the

unit’s specified span gas.

9

Remove the beaker from the sensor. Carefully remove any

ampoule remains from the gas detector and beaker.

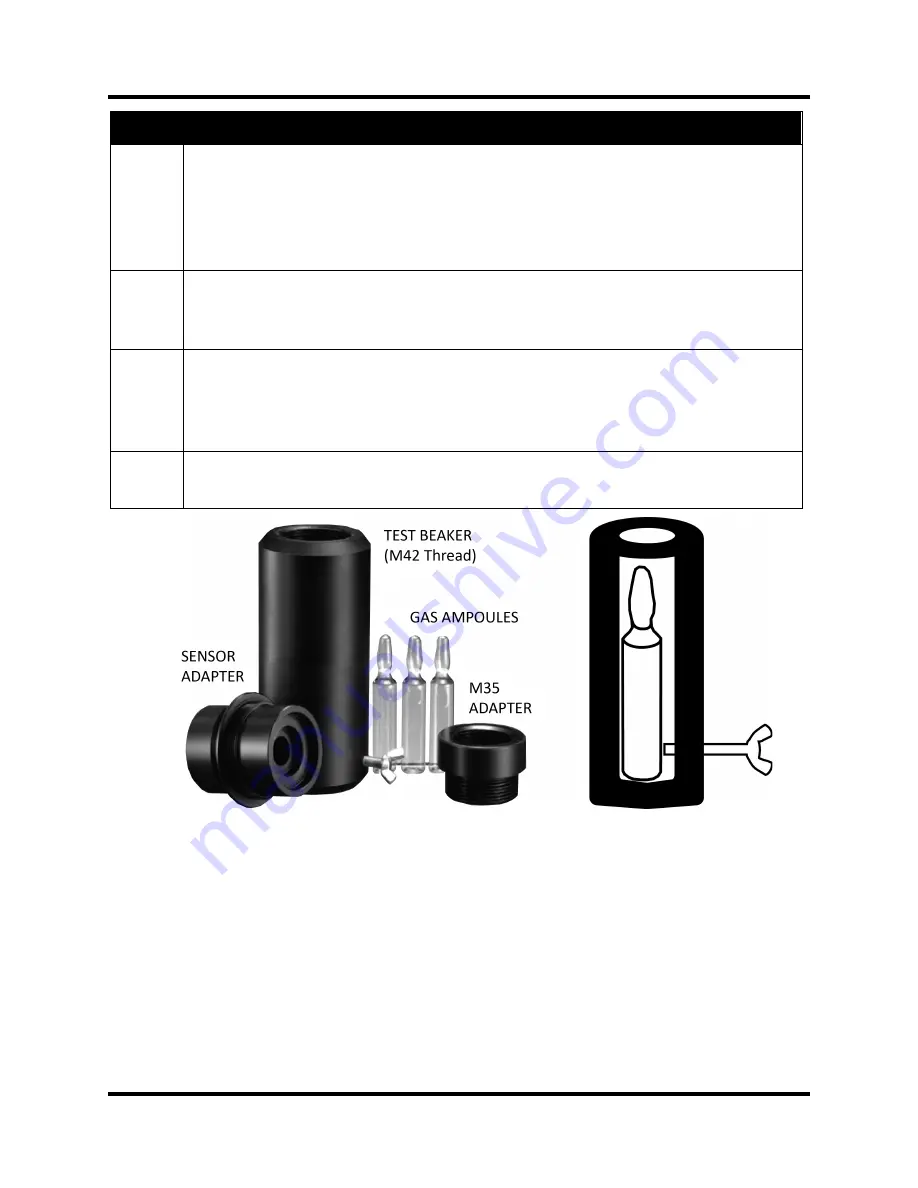

Figure 10. Gas Ampoules for Bump Testing

6.3. Calibration Overview

There are two adjustments required: zero and span. They are monitored at 0V

and VS using a 0-5V scale. If the sensor range is 0-1000 ppm, then 5V=1000

ppm.

Murco offers a calibration kit that consists of a calibration gas cylinder, a flow

regulation valve with flexible non-absorbent tubing and vented calibration

hood. Tools required: