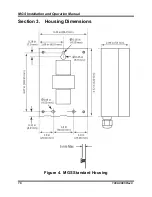

MGS Installation and Operation Manual

1000-0085 Rev 0

9

2.1. General Placement Guidelines

NOTE:

The MGS should be installed plumb and level and securely

fastened to a rigid mounting surface.

Sensors must be located within the appropriate wire lengths from the central

control unit (if used).

In all cases the sensor supplied is designed for maximum sensitivity to a

particular gas. However, in certain circumstances false alarms may be caused

by the occasional presence of sufficiently high concentrations of other gaseous

impurities. Examples of situations where such abnormalities may arise include

the following:

•

Plant room maintenance activity involving solvent or paint fumes or

refrigerant leaks.

•

Accidental gas migration in fruit ripening/storage facilities (bananas -

ethylene, apples - carbon dioxide).

•

Heavy localised exhaust fumes (carbon monoxide, dioxide, propane)

from engine-driven forklifts in confined spaces or close to sensors.

Murco recommends setting the alarm delay to minimise false alarms.

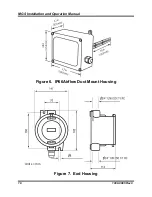

2.2. Components and Access Overview

NOTE:

The wiring is the same for the electro-chemical, semi-

conductor, and infrared models. The controller wiring is the same

for all controllers.

There is a 5-minute power-up delay to allow the sensor to stabilise. Refer to

Figure 2 and Figure 3 for internal components and wiring.