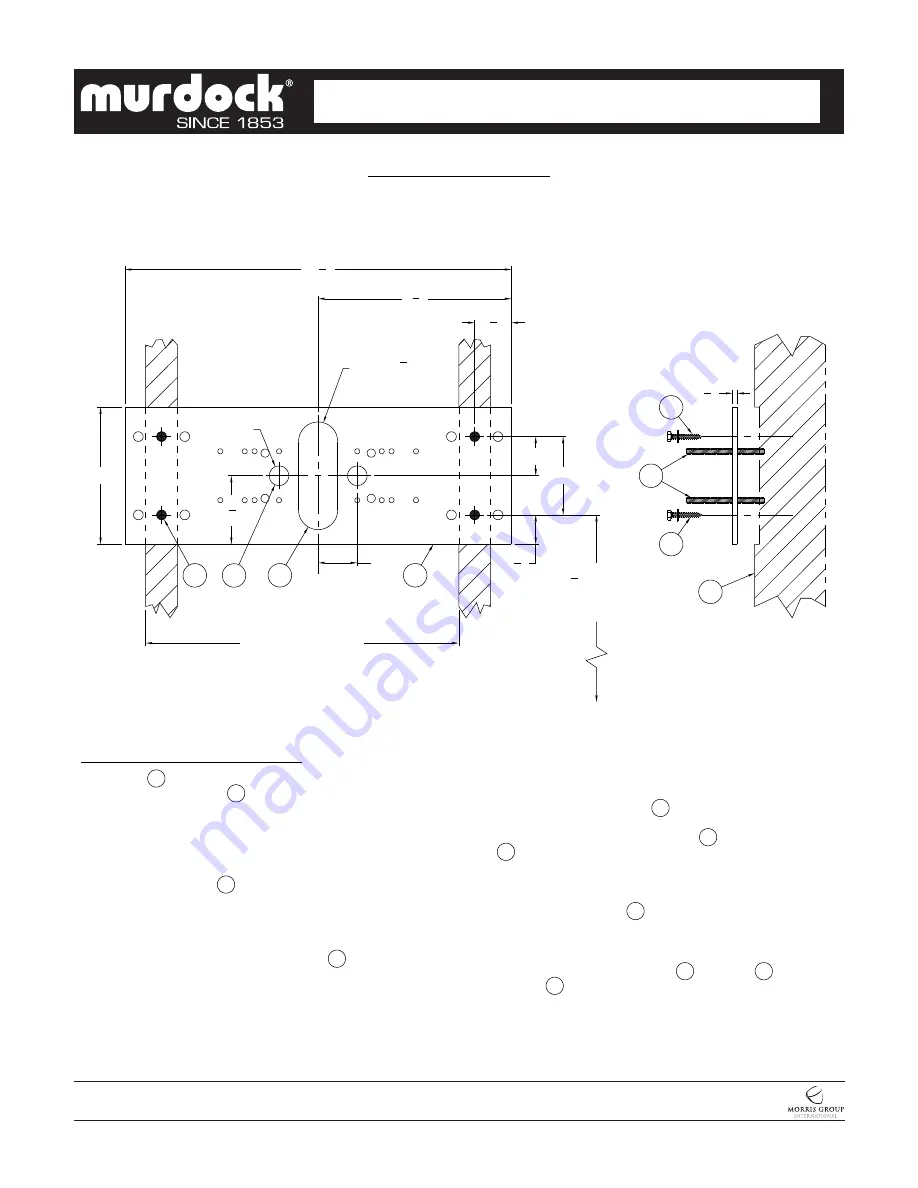

DIMENSIONAL DRAWING

Prior to roughing in, consult with local, state, and federal codes for proper mounting height.

A151-VR

Page 4 of 11

Date:

10/28/2020

7021-020-001

MURDOCK MFG. •

15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com

Member of

16"

COMMON WALL

STUD SPACING

4"

CL

1

1

2

"

2"

2"

Ø1"

3

1

2

"

1

4

"

1

7

8

"

19

3

4

"

7"

9

7

8

"

Ø2" x 5

1

2

"

LONG OBROUND

PLATE 1 INTENDED TO BE RECESSED FLUSH WITH

SUPPORT FRAMING 2 PROVIDED BY INSTALLER.

FRAME & BLOCK OUT SUPPORT USING DIMENSIONS

SHOWN. FRAME SHOULD SUPPORT 300 LBS MINIMUM.

MOUNTING PLATE 1 IS 1/4" THICK AND INCLUDES

(18) 1/2" DIAMETER PUNCHING FOR ANCHORING

HARDWARE BY OTHERS.

STRIKE A LEVEL HORIZONTAL CHALK LINE TO

LOCATE BOTTOM MOUNTING HOLES 3 . REFERENCE

DISCHARGE HEIGHT REQUIREMENTS FOR YOUR

MODEL AND FACILITY TO DETERMINE CORRECT

HEIGHT AT FINISHED FLOOR (AFF).

AFTER POSITIONING PLATE CORRECTLY, FIX PLATE

TO WALL USING APPROPRIATE, INSTALLER PROVIDED

ANCHORING HARDWARE 4 .

MAKE UP APPROPRIATE SUPPLY 5 AND WASTE

6 ROUGHS THROUGH MOUNTING PLATE OPENINGS.

LOCATE 5/16" THREADED STUDS MOUNTING HARDWARE

AND THREAD STUDS 7 THRU PLATE SO THAT A

MINIMUM OF 1-1/4" OF THREAD PROJECTS BEYOND

THE FINISHED WALL MATERIAL.

PROTECT THREADED STUDS 7 , SUPPLY 5 AND

WASTE 6 ROUGHS WHILE FINISHING WALL.

INSTALLATION INSTRUCTIONS:

A-

B-

C-

D-

E-

F-

G-

A STRAIGHT SUPPLY STOP IS RECOMMENDED.

(PLATE MAY BE MOUNTED ON FINISHED WALL, PROVIDED

FRAME SUPPORTS 300 LBS MINIMUM.)

4

4

7

2

1

6

5

3

27

1

4

"

FOR

33"

DISCHARGE

HEIGHT

CONTEMPORARY WATER COOLERS

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

DRINKING FOUNTAINS