7. Completely flush water supply lines of all foreign debris, before connecting to the fixture.

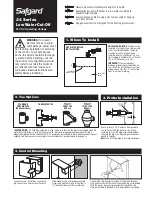

3. Provide mounting surface, adequate to support the fixture and loads on the fixture.

1. Read all installation instructions carefully, before proceeding.

PRIOR TO INSTALLATION:

4. Provide rough-ins as shown on the roughing-in and dimensional drawing, including water supply, drain pipe

and gravel drain well. (See rough-in details)

5. It is common for electrical equipment to be grounded to water lines either within a structure or away; otherwise,

remains unchanged by the materials in the water cooler. Every attempt should be made to prevent this kind of

grounding from generating feedback into the water cooler creating electrolysis. Electrolysis will cause a

metallic taste or cause water content to increase.

2. Carefully remove all fixture components from packaging, preventing scratching or damage. Inspect fixture and

all parts from damages and all parts that are bolted on.

6. Electrical Receptacle(s) must be wired to a GFCI protected circuit. Fixture must be earth grounded per NEC

(National Electrical Code).

IMPORTANT:

5. Do NOT solder tubes inserted into the chiller, bottle filler or the fountain strainer as damage to the o-rings on

the push-in fittings may result.

7. Power supply must be identical in voltage, cycle and phase to that specified on the chiller data plate. Refer to

submittal.

1. Water Supply Service Stop Valve, Water Connections and Electrical Connections to be supplied by others in

accordance with local codes.

2. Provide 4” minimum clear space in front of bottom trim panel and above in-wall chiller to allow for proper

ventilation.

3. Waste is 1-1/4” Outer Diameter. Chiller water inlet is 3/8” Outer Diameter copper tube. Chiller water outlet is

3/8” Outer Diameter copper tube. Drinking Fountain water inlet is 3/8” Outer Diameter copper tube. Bottle

Filler water inlet is 3/8” Outer Diameter copper tube. Water line by others from in-wall chiller to drinking

fountain must have adequate insulation.

4. Completely flush supply lines of all foreign debris before connecting to fixture. Water cooler designed to not

cause problems with taste, odor, color, or sediment. Optional Water Filter (WF1), is available should any of

these problems arise from the water supply.

6. All burrs must be removed from outside of cut tubes before inserting into strainer or other components.

8. This unit must be grounded per the requirements of applicable electrical codes.

9. WARNING: Warranty is voided if installation is not made following current Murdock Mfg. installation

instructions and if components are assembled to the fixture that are not approved by Murdock Mfg.

10. Fixture operates within water pressure range of 174 kPa (25 psig) to 724 kPa (105 psig). Murdock Mfg. will

not warranty chiller damaged when connected to supply lines with flow pressure lower than 174 kPa (25

psig) or higher than 724 kPa (105 psig). A pressure regulator must be furnished by others on supply line if

inlet pressure is greater than 724 kPa (105 psig).

11. Due to cold waste water, Murdock Mfg. recommends that waste piping supplied by installer be insulated

appropriately to prevent excessive condensation.

12.

Per UPC 609.10-All building water supply systems in which quick acting valves are installed shall be

provided with devices to absorb the hammer caused by high pressure resulting from the quick closing of the

valve. These pressure-absorbing devices shall be approved mechanical devices. Water pressure-absorbing

devices shall be installed as close as possible to the quick closing valve

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

CONTEMPORARY WATER COOLERS

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

DRINKING FOUNTAINS

A152.8-BF4

Page 6 of 23

Revised:

07/18/18

7020-949-001

MURDOCK MFG. •

15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com

Member of