-- 12 --

T1725e

7

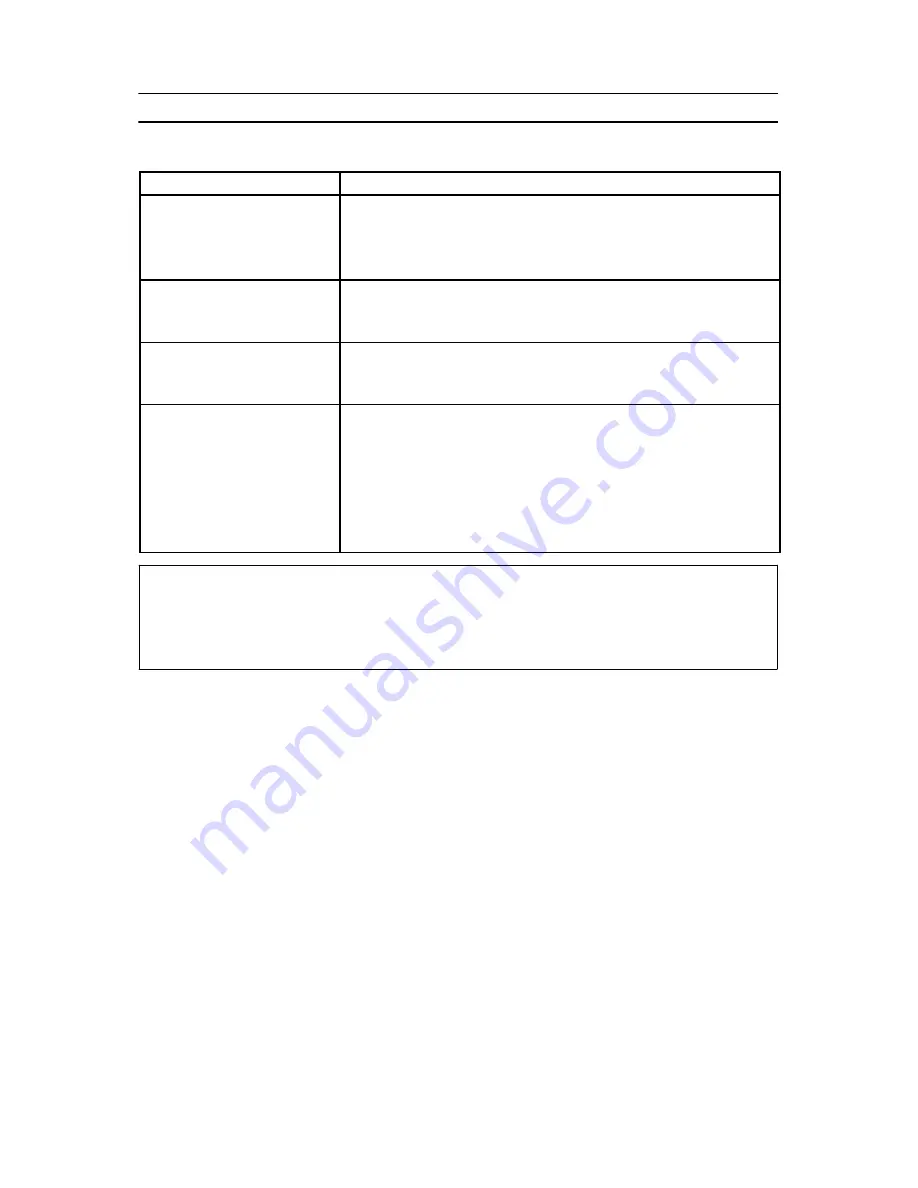

FAULT TRACING

Try these recommended checks and inspections before sending for an authorised service technican.

Type of fault

Actions

No arc

S

Check that the mains power supply switch is turned on.

S

Check that the welding current supply and return cables are

correctly connected.

S

Check that correct current value is set.

Welding current is interrupted

during welding

S

Check whether the thermal overload trip has operated

(indicated by the orange lamp on the front).

S

Check the main power supply fuses.

Thermal overload trips

operate frequently

S

Check to see whether the air inlets/outlets are clogged.

S

Make sure that you are not exceeding the rated data for the

power source (i.e. that the unit is not being overloaded).

Poor welding performance

S

Check that the welding current supply and return cables are

correctly connected.

S

Check that the correct current value is set.

S

Check that the correct welding wires are being used.

S

Check the main power supply fuses.

S

Check the wire feed unit -- if proper rolls are applied and

properly set the pressure of the wire feeder’s pressure rollers

Tradesmig 171/201/251 is designed and tested in accordance with the international and

European standards IEC/EN 60974--1 and EN 60974--10. It is the obligation of the servi-

ce unit which has carried out the service or repair work to make sure that the product

still conforms to the said standard.

Summary of Contents for Tradesmig 171

Page 13: ...Diagram 13 dT1725 Tradesmig 171 240V valid untill June 2008 ...

Page 14: ... 14 dT1725 Tradesmig 171 240V valid from July 2008 ...

Page 15: ... 15 dT1725 Tradesmig 201 240V valid untill June 2008 ...

Page 16: ... 16 dT1725 Tradesmig 201 240V valid from July 2008 ...

Page 17: ... 17 dT1725 Tradesmig 251 240V valid untill June 2008 ...

Page 18: ... 18 dT1725 Tradesmig 251 240V valid from July 2008 ...

Page 22: ... 22 hints ...

Page 23: ... 23 hints ...

Page 24: ... 24 hints ...