27

AUGER SHEAR PIN REPLACEMENT

The augers are secured to the auger shaft with special shear pins that are

designed to break if an object becomes lodged in the auger housing. Use

of a harder grade shear pin will reduce the protection provided by the

shear pin.

WARNING: Do not go near the discharge chute or auger

when the engine is running. Do not run the engine if

any cover or guard is removed.

Under most circumstances, if the auger strikes an object which could

cause damage to the unit, the shear pin will break. This protects the gear

box and other parts from damage.

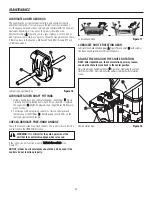

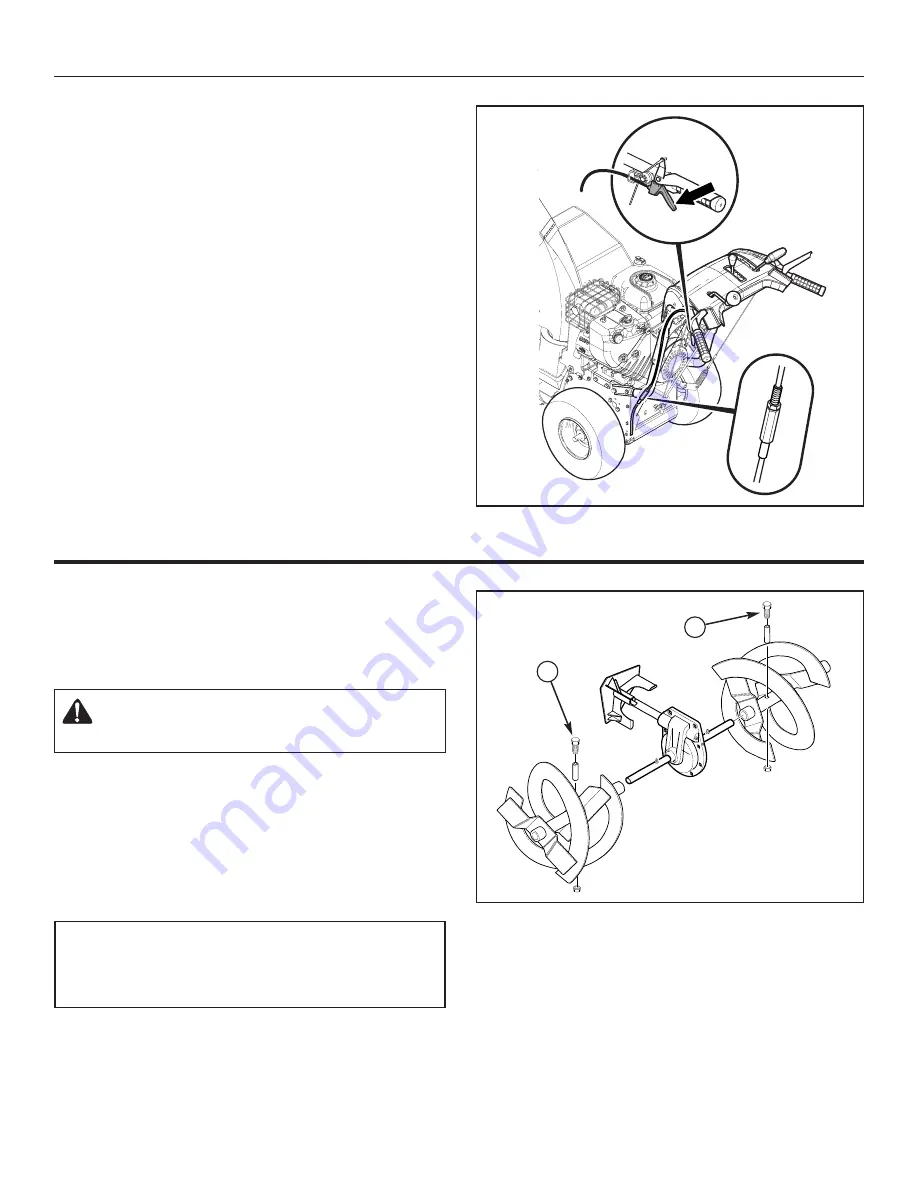

The shear pins (A

A, Figure 34) are located on the auger shaft. Replace a

broken shear pin as follows.

1. Tap out the broken shear pin with a pin punch.

2. Install a new shear pin and cotter pin. Bend the ends of the cotter pin

down.

IMPORTANT: Do not replace shear pins with anything other

than the correct grade replacement shear pin. Use of bolts,

screws, or harder grade shear pins can result in equipment

damage.

Replacing Broken Shear Pin

Figure 34

A

A

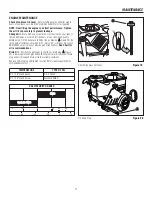

Easy-Turn

TM

Cable Adjustment

Figure 33

EASY-TURN™ CABLE ADJUSTMENT

If the Easy-Turn™ cable has stretched, the gears will not disengage when

the control lever is activated. Adjust the cable using the following proce-

dure.

1. Turn the engine off and disconnect the spark plug wire.

2. Loosen the jam nut (see Figure 33).

3. Turn the adjustment nut to lengthen or shorten the cable. The cable

should be tightened just until all slack is removed from the lever,

however it must not engage the Easy-Turn™ release without de-

pressing the control lever.

4. Tighten the jam nut.

MAINTENANCE