14

TO CHANGE ENGINE OIL

1. Disconnect spark plug wire from spark

plug and place wire where it cannot

come in contact with plug.

2. Be sure lawn mower is on level sur-

face.

NOTE

: Oil will drain more freely when

warm. Catch oil in a suitable container.

3. Remove bottom oil drain plug.

4. After oil has drained completely,

replace oil drain plug and tighten se-

curely.

5. Fill engine with oil. (See “ADD OIL” in

the Operation section of this manual).

6. Reconnect spark plug wire to spark

plug.

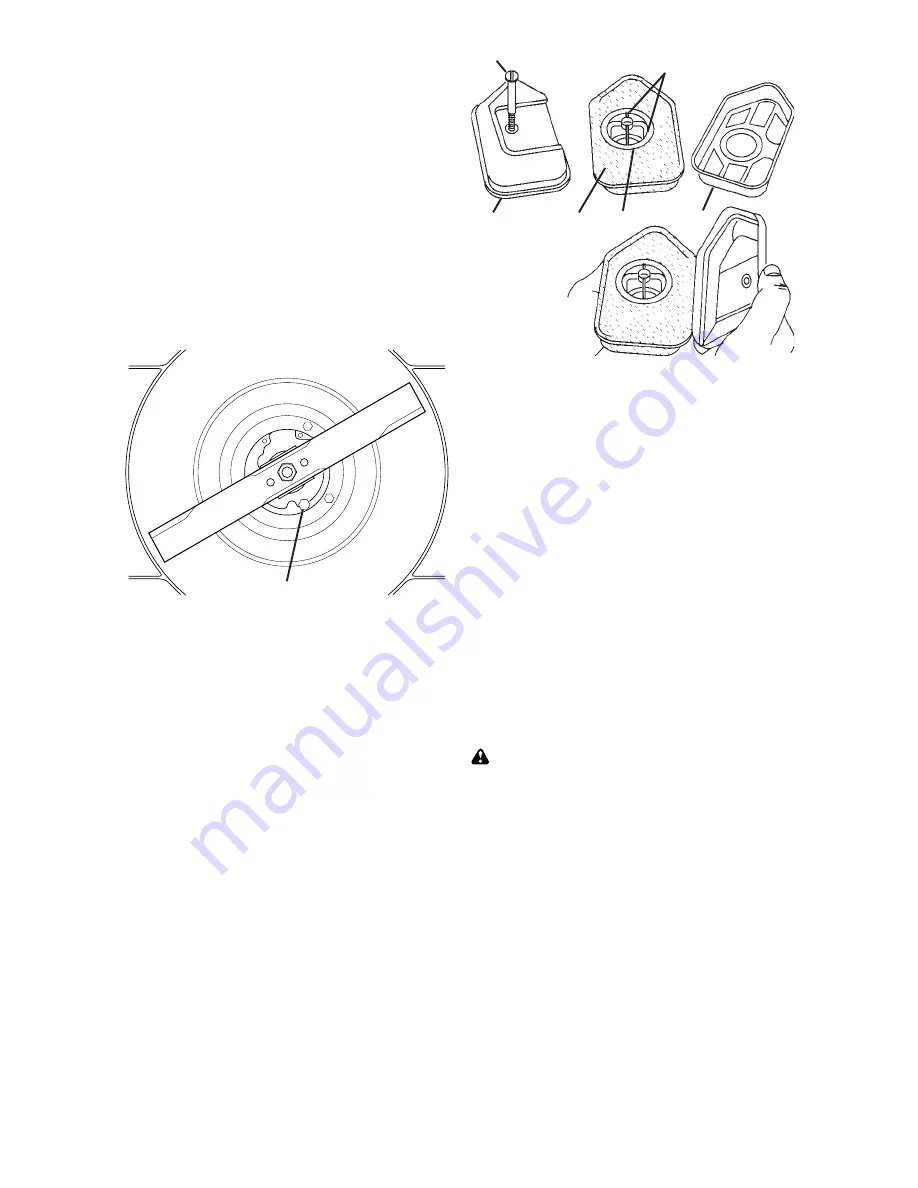

AIR FILTER

Your engine will not run properly and may be

damaged by using a dirty air fi lter. Clean the

element after every 25 hours of operation or

every season. Replace the air fi lter every

100 hours of operation or every season,

whichever occurs fi rst. Service air cleaner

more often under dusty conditions.

TO CLEAN AIR FILTER ELEMENT

1.

Remove screw.

2. Re move air cleaner carefully to pre vent

dirt from en ter ing carburetor.

3. Take air cleaner apart and clean air

fi lter element.

4. Wash fi lter element in liquid de ter gent

and water.

5. Wrap fi lter element in cloth and

squeeze dry.

6. Lightly coat fi lter element with clean

engine oil. Squeeze in towel to re move

excess oil. Do not satu rate.

7. Reassemble parts and put back on

carburetor.

MUFFLER

Inspect and replace corroded muffl er as it

could create a fi re hazard and/or dam age.

SPARK PLUG

Replace spark plug at the beginning of

each mowing season or after every 100

hours of operation, whichever occurs

fi rst. Spark plug type and gap setting

are shown in the “PROD UCT SPEC I FI C-

A TIONS” section of this manual.

CLEANING

IMPORTANT:

For best performance, keep

mower housing free of built-up grass and

trash. Clean the underside of your mower

after each use.

CAUTION:

Disconnect spark plug wire

from spark plug and place wire where it

cannot come in contact with plug.

• Clean the underside of your lawn mower

by scraping to remove build-up of grass

and trash.

• Clean engine often to keep trash from

accumulating. A clogged engine runs

hotter and shortens engine life.

• Keep fi nished surfaces and wheels free

of all gasoline, oil, etc.

• We do not recommend using a garden

hose to clean lawn mower unless the

electrical system, muffl er, air fi lter and

carburetor are covered to keep water

out. Water in engine can result in short-

ened engine life.

ASSEMBLE ONE OF THESE LOW POINTS

TOWARDS NARROW EDGE OF ELEMENT

Body

Screw

Cup

Element

ASSEMBLE SO LIP

EXTENDS OVER

EDGE OF

AIR CLEANER

BODY

LIP WILL FORM

PROTECTIVE

SEAL WHEN

COVER IS ASSEMBLED

Lip

Drain plug