MAINTENANCE

24

F-040735L

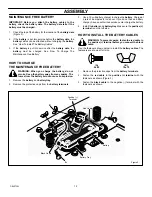

HOW TO ADJUST THE SHIFT LEVER

If the NEUTRAL position on the shift lever does not match neutral

on the gearbox, adjust the shift lever as follows.

1.

Stop the engine.

2.

Disconnect the adjuster nut from the shifter bracket

(Figure 17).

3.

Make sure the shift lever is in the NEUTRAL position.

4.

Push the unit forward. Make sure the gearbox is in neutral.

5.

To align the adjuster nut with the hole in the shifter bracket,

turn the adjuster nut.

6.

Connect the adjuster nut to the shifter bracket.

7.

Make sure the NEUTRAL position on the shift lever matches

neutral on the gearbox.

Adjuster Nut

Hair

Pin

Shift

Link

Shifter

Bracket

Motion Drive Belt

Figure 17

Shift Lever

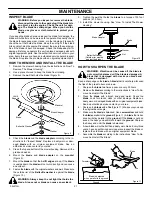

MAINTENANCE FREE BATTERY

HOW TO REMOVE THE BATTERY

To charge or clean the battery, remove the battery from the unit as

follows.

WARNING: To prevent sparks, disconnect the black

battery cable from the negative (-) terminal before you

disconnect the red cable.

WARNING: The battery contains sulfuric acid which is

harmful to the skin, eyes and clothing. If the acid gets

on the body or clothing, wash with water.

1.

Disconnect the black cable from the negative (-) terminal

(Figure 18).

2.

Disconnect the red cable from the positive (+) terminal.

3.

Lift the battery tray and the battery out of the unit.

HOW TO CLEAN THE BATTERY

1.

Remove the battery.

2.

Wash the battery with a solution of one gallon of water and four

tablespoons of baking soda (sodium bicarbonate). Make sure

the solution does not get into the battery cells.

3.

Clean the terminals and the ends of the cables with a wire

brush.

4.

Install the battery.

5.

To prevent corrosion, apply grease to the battery terminals.

HOW TO CHARGE THE BATTERY

WARNING: When you charge the battery, do not

smoke. Keep the battery away from any sparks. The

fumes from the battery acid can cause an explosion.

1.

Before you charge the battery, remove the battery.

2.

To charge the battery, use a 12 volt battery charger. Charge at

a rate of 6 amperes for 1 hour.

3.

Install the battery.

WARNING: To prevent sparks, fasten the red cable to

the positive (+) terminal before you connect the black

cable.

4.

Fasten the red cable to the positive (+) terminal with the fas-

teners as shown.

5.

Fasten the black cable to the negative (-) terminal with the fas-

teners as shown.

Positive (+)

Terminal

Black Cable

Red Cable

Battery Tray

Battery

Figure 18

Carriage Bolt

Wing Nut

Carriage Bolt

Summary of Contents for 405000x8C

Page 35: ...NOTES 35 F 040735L ...

Page 50: ...50 F 040735L ...