MAINTENANCE

21

F–030700L

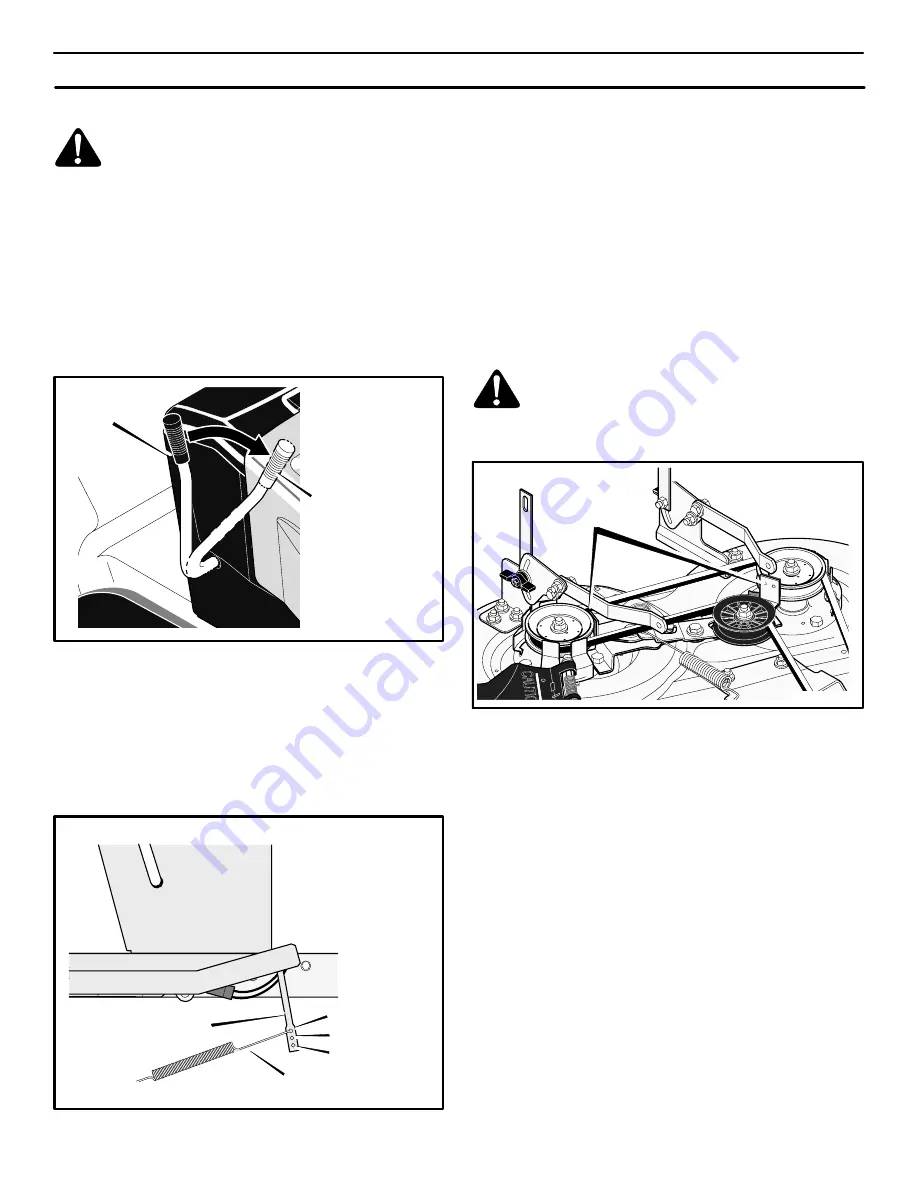

HOW TO ADJUST THE BLADE ROTATION CONTROL

WARNING: To prevent an injury, the blade rotation

control must operate correctly.

In normal usage, the blade rotation control will not require an

adjustment. However, if the cutting performance decreases or the

quality of cut is poor, make the following changes.

1.

When you mow, make sure the throttle control in in the FAST

position.

2.

Move the blade rotation control to the DISENGAGE position

(Figure 12).

3.

Stop the engine. Disconnect the wire from the spark plug.

Blade Rotation Control

Engage Position

Disengage

Position

Figure 12

4.

Check the blade(s). Keep a sharp edge on the blade(s). A blade

that is not sharp will cause the tips of the grass to become

brown.

5.

Disconnect the blade drive spring from the blade control

rod. Move the blade drive spring to the middle hole

(Figure 13). This will increase the tension on the mower drive

belt.

Figure 13

Blade

Control Rod

Blade Drive Spring

Top Hole (New Belt)

Middle Hole

Bottom Hole

DISENGAGE POSITION

6.

Attach the wire to the spark plug. Mow for a short distance and

again check the quality of cut. If necessary, move the blade

drive spring to the bottom hole.

7.

Again check the quality of cut. If the quality of cut has not im-

proved, replace the mower drive belt. See “How To Replace

The Mower Drive Belt”. If replacing the belt does not correct the

problem, take the unit to an authorized service center.

8.

Move the blade rotation control to the DISENGAGE posi-

tion. Stop the engine. Disconnect the wire from the spark plug.

Check the operation of the blade brake. Rotate the pulleys with

your hand. Make sure the brake pads are pressed tightly

against the pulleys (Figure 14).

WARNING: If the brake pads do not press tightly

against the pulleys, take the unit to an authorized

service center.

Blade Brake

Brake Pad

Against Pulley

Figure 14

9.

Move the blade rotation control to the ENGAGE position.

Check the pads for the blade brake. If the pads are excessively

worn or damaged, replace the brake pad assemblies. Correct

replacement parts and assistance are available from an autho-

rized service center.

10. Attach the wire to the spark plug. Mow for a short distance and

again check the operation of the blade rotation control.

11. When you move the blade rotation control to the

DISENGAGE position, all movement will stop within five se-

conds. If there is movement of the belt or the blades continue

to rotate, engage and disengage the blade rotation control

five times to remove any excess rubber from a new mower

drive belt. If you need assistance, take the unit to an autho-

rized service center.

12. If you replace the mower drive belt, move the blade drive

spring to the top hole (Figure 13).