ENGLISH

16

F-041035L

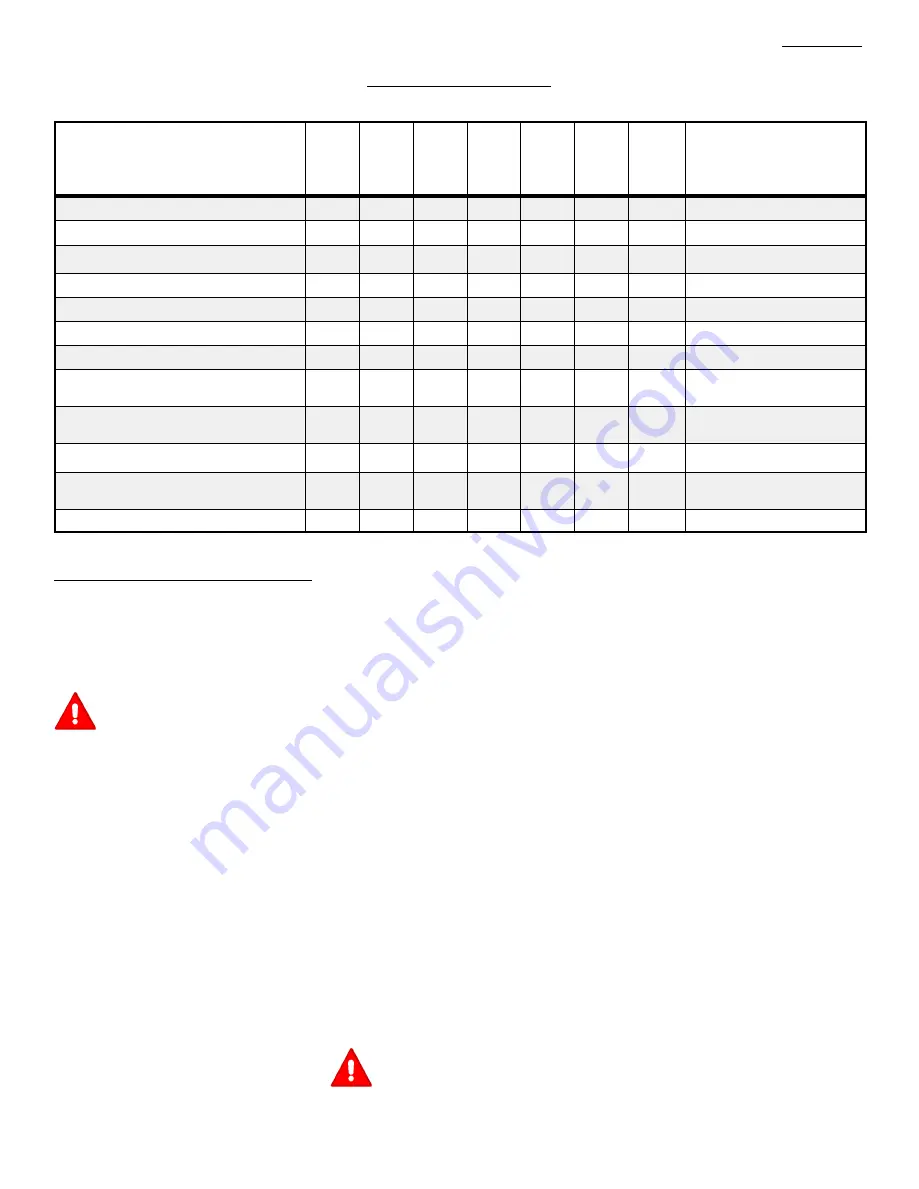

MAINTENANCE CHART

CUSTOMER RESPONSIBILITIES

SERVICE RECORDS

Fill in dates as you

complete regular

service.

Before

Each

Use

First

2

Hours

Every

5

Hours

Every

10

Hours

Every

25

Hours

Each

Season

Before

Storage

SERVICE DATES

Check Engine Oil Level

√

√

√

Change Engine Oil

√

√

Check And Tighten All Screws and Nuts

√

√

Check Spark Plug

√

√

Adjust Drive Belt

√

√

√

Check Fuel

√

Drain Fuel

√

Check Auger Clutch Cable Adjustment

(See Cable Adjustment)

√

√

Check Traction Clutch Cable Adjustment

(See Cable Adjustment)

√

√

Lubricate All Pivot Points

√

√

Lubricate Auger Shaft

(See Shear Bolt Replacement)

√

√

Lubricate Drive Chains and Sprockets

√

√

MAINTENANCE

NOTE: Illustrations begin on page 3.

Use the following maintenance section to keep

your unit in good operating condition. All the

maintenance information for the engine is in the

engine manufacturer’s instructions. Before you

start the engine, read this book.

WARNING: Before you make an in-

spection, adjustment (except

carburettor), or repair, disconnect

the wire from the spark plug.

General Recommendations

The warranty on this snow thrower does not cov-

er items that have been subjected to operator

abuse or negligence. To receive full value from

the warranty, the operator must maintain the

snow thrower as instructed in this manual.

Some adjustments must be made periodically to

properly maintain the snow thrower.

After Each Use

G

Check for any loose or damaged parts.

G

Tighten any loose fasteners.

G

Check and maintain the auger.

G

Check controls to make sure they are

functioning properly.

G

If any parts are worn or damaged, replace

immediately.

All adjustments in the

Maintenance

section of

this manual should be checked at least once

each season.

As Required

The following adjustment should be preformed

more than once each season.

1. Adjust the auger drive belt after the first 2 to

4 hours, again at mid-season, and twice

each season thereafter. See “How To Adjust

The Auger Drive Belt” in the Maintenance

section.

Lubrication

Every 10 Hours

1. Lubricate the

Zerk fittings (1

) every ten

hours with a grease gun.

2. Each time a shear bolt is replaced, the auger

shaft must also be greased.

3. Lubricate all pivot points.

Every 25 Hours

(Figure 15)

Chute Rotation Gear

(Figure 4)

Lubricate the

chute rotation gear (1)

with automotive type oil.

Chains

1.

(Figure 2)

Move the

speed shift lever (6)

to

first gear.

2. Remove the gas from the gas tank. Stand

the snow thrower up on the front end of the

auger housing (4)

.

WARNING: Drain the gasoline out-

doors, away from fire or flame.

3.

(Figure 22)

Loosen the

bolts (3)

on each

side of the

bottom panel (2)

.

4. Remove the

bottom panel (2).

5.

(Figure 15)

Lubricate the

chains (5)

with a

chain type lubricant.

6. Wipe the

hexshaft and sprockets (6)

with

5W30 motor oil.

NOTE: If grease or oil come in contact

with the disc drive plate (1) or the friction

wheel (3), damage can result. Clean off

any oil or grease with a alcohol base sol-

vent.

7.

(Figure 22)

Install the

bottom panel (2)

.

8. Tighten the

bolts (3)

on each side of the

bot-

tom panel (2)

.

Items Not To Lubricate

(Figure 15)

1. Do not lubricate the

hex shaft and sprock-

ets (6)

. All bearings and bushings are life-

time lubricated. For storage, put a slight

amount of 5W-30 motor oil on a cloth and

wipe the

hex shaft and sprockets (6)

to

prevent rust.

2. If grease or oil comes in contact with the

disc drive plate (1)

or the

friction wheel

(3)

, the

friction wheel (3)

can be damaged.

Make sure to thoroughly clean the

disc drive

plate (1)

and the

friction wheel (3)

.

CAUTION: Any greasing or oiling of the

above components can cause contamina-

tion of the friction wheel (3). If the disc

drive plate (1) or the friction wheel (3) be-

come contaminated with grease or oil,

damage to the friction wheel will result.

3. The auger gear case is lubricated at the fac-

tory and does not require additional lubrica-

tion. If for some reason the lubricant leaks

out, have the auger gear case checked by a

factory authorized service center.

Summary of Contents for 627808x84B

Page 4: ...4 F 041035L 5 4 11 10 2 6 7 8 9 10 7 8 1 2 3 4 5 6 9 2 4 1 3 10 11 1 2 ...

Page 5: ...5 F 041035L 2 5 1 12 13 1 1 2 3 6 14 1 1 6 5 5 1 3 7 1 A 15 16 6 2 1 3 1 4 17 6 5 7 8 ...

Page 7: ...7 F 041035L 23 2 3 4 A 24 4 5 6 8 4 25 26 2 3 4 3 4 5 6 27 ...

Page 8: ...8 F 041035L 11 3 3 2 10 28 11 12 15 29 11 7 16 16 19 20 8 7 14 13 13 7 30 31 17 17 ...

Page 9: ...9 F 041035L 32 2 3943 2 9524 2 73826 ...

Page 31: ...31 F 041035L Parts List Model 627808x84B Liste de pièces Modèle 627808x84B ...

Page 51: ...51 F 041035L ...