As from: 02.05.2006

Murrplastik Systemtechnik - ACS Werner Tubach

29

8902864602

MP Engraving unit

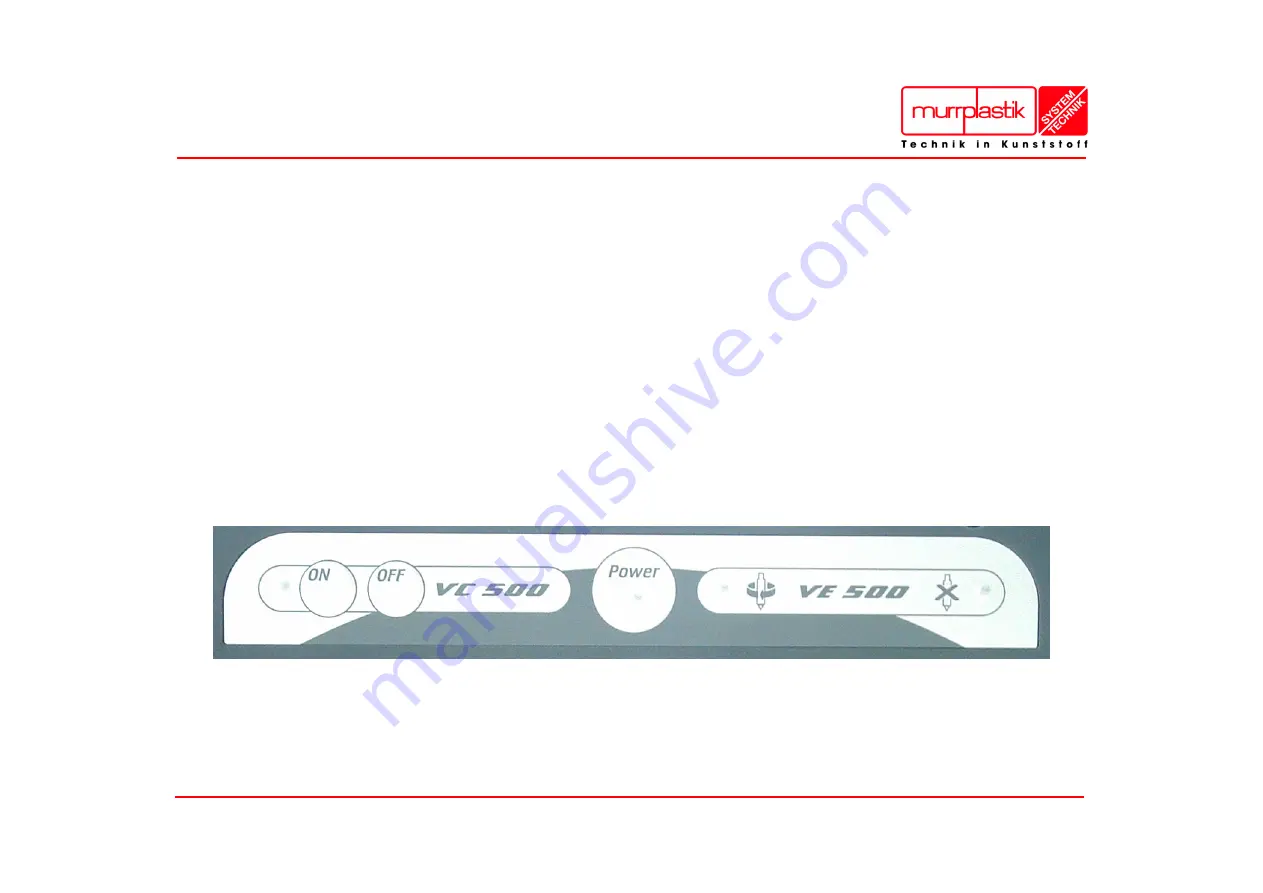

9.0 Testing spindle and vacuum cleaner

Switch on the controller and press the ON and OFF buttons at

the same time for at about 5 seconds.

Vacuum cleaner and controller will be activated.

Push the ON button to increase spindle rotation speed, push

OFF to lower rotation speed.