17/16 HAMMERED DULCIMER KIT

Assembly Instructions

1 assembly instructions

1 tuning chart on transparency

66 tuning pins

33 rh 1” screws for top (square drive)

2 black delrin rods (24” each)

2 brass tubes, 3/8” dia (21” each)

1 tuning wrench

4 walnut plugs, 3/8” dia

4 wood screws, 1-1/4”

1 drill bit, 3/16”

1 drill bit, 9/64”

1 square drive #2 bit for top screws

Music wire:

4 ea. - .032” dia. loop-end wound strings

8 ea. - .024” dia. loop-end wound strings

20 ft of .016” dia. music wire

50 ft of .018” dia. music wire

50 ft of .020” dia. music wire

75 ft of .022” dia. music wire

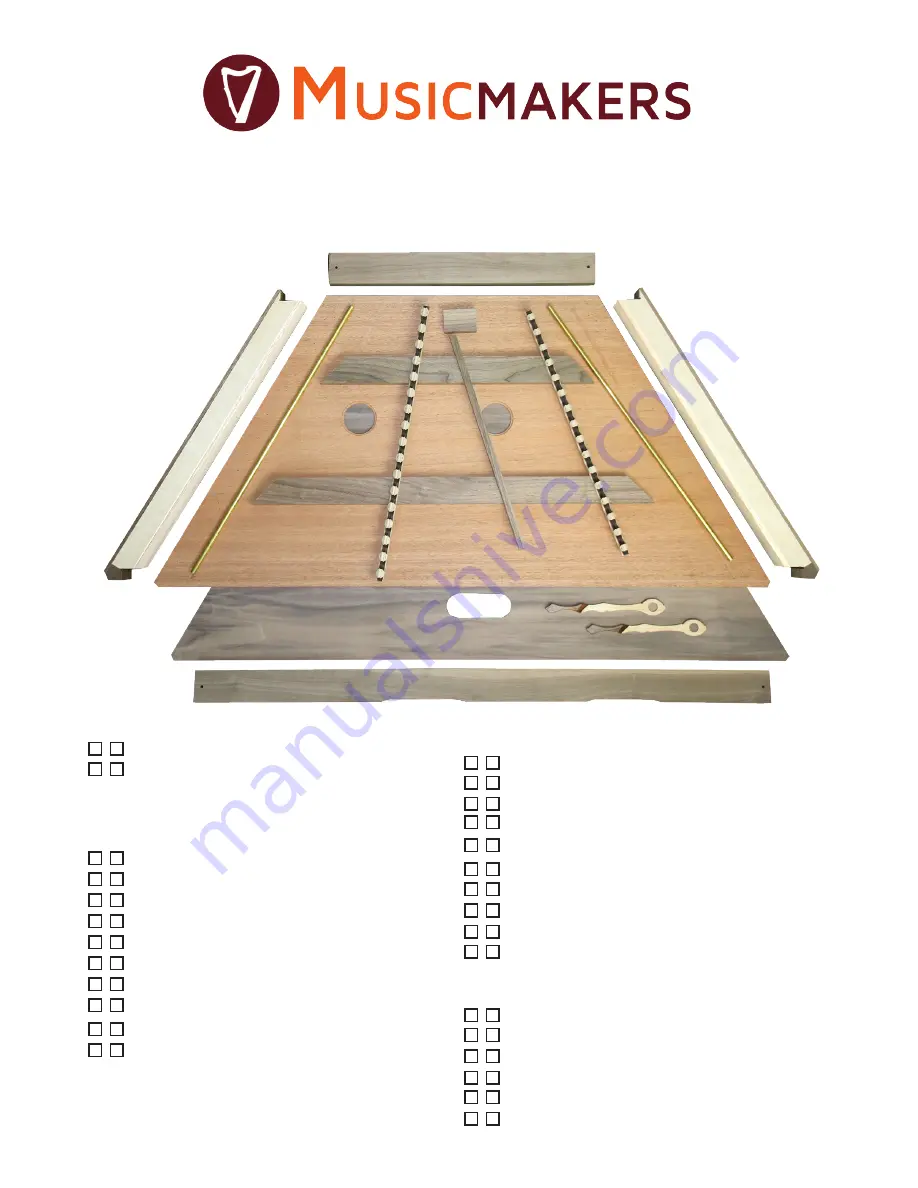

a) 1 back (1/4” plywood)

b) 1 soundboard/top (solid wood)

c) 2 pinblocks (walnut and maple)

d) 1 long front rail (walnut)

e) 1 shorter back rail (walnut)

f) 2 inner braces (hardwood)

g) 2 bridges (maple)

h) 1 tone bar (hardwood)

i) 1 bridge support block

j) 1 pair playing hammers

WOOD PARTS

HARDWARE

Musicmakers

14525 61st ST CT N

Stillwater, MN 55082

A

D

F

G

H

I

J

G

F

E

B

C

C

Updated November 2019