Operating instruction: H002 / 0938 / 0940

Edition: 01/2016

Subject to alterations.

17

5

Handling

5.1

General

Heating presses are electrical heating devices for use in fabricating (splicing) belting material that

can withstand maximum temperatures of 200°C.

There are two basic methods of controlling the heating procedure,

a.)

An automatic one using a control unit that carries out the heating and cooling phases on special

heating presses automatically after the operator has programmed in and

b.)

A manual one where the operator supervises and carries out independently all the cycles.

Note:

When making melting splices always observe the splicing instructions for the belt type to be spliced.

5.2

Inserting the belt into the heating press

1. Prepare the two belt ends according to the required connection (Z-splice, wedged splice etc.).

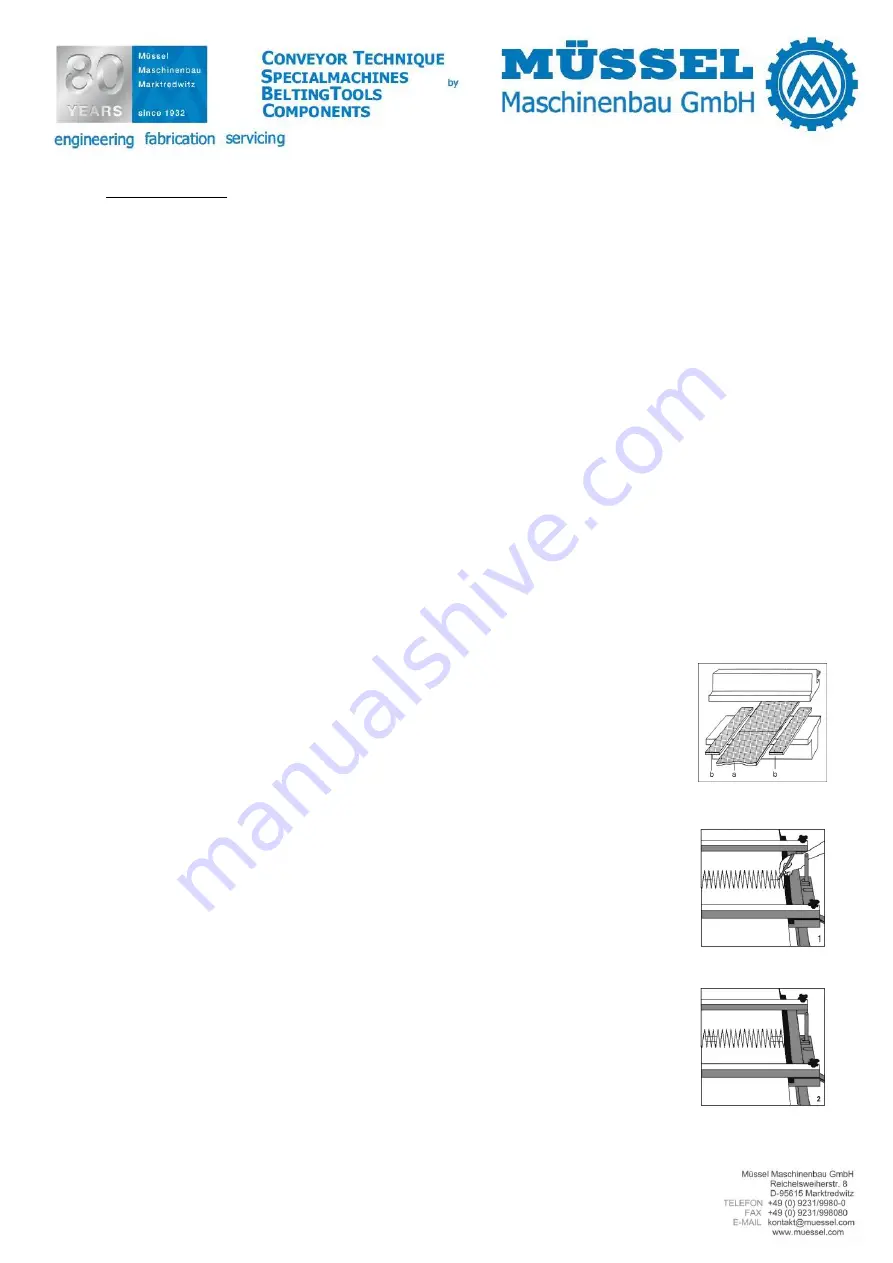

2. Place the pressure equalizing metal sheet on the bottom part of the press and cover them by

silicone fabric No. 1.

3. The both belt ends must be centrically placed on the pressure equalizing metal sheet (with the

operating side reversed).

4. Place the shim bars (or material of the same thickness) to the left and right next to the ends of

the belt (refer to the following figure).

Note:

Always fold out the areas to be pressed to the full width. If the belting

material is a) narrower than the area to be pressed, (so that the press

do not flexing) extra pieces in the same thickness or several shim bars

of the corresponding width must also be inserted

5. Please entirely push together and mark the Z-splice (Fig. 1).

6. Place the top hold-down bar and tighten it slightly.

7. Centre and align the belt (Fig. 2), adjust the distance between the

two belt ends according to the instructions for the respective belt type

(belts mostly about 5 mm).

8. Fill up the pneumatically hold-down bar with compressed air.

Maximum 4 bars compressed air.