Operating instruction: H002 / 0938 / 0940

Edition: 01/2016

Subject to alterations.

9

3

Product description

3.1

Components and proper usage

Heating presses are electrical heating devices for use in fabricating (splicing) belting material that

can withstand maximum temperatures of 200°C. Heating presses are used to splice belting material

using pressure and temperature. Depending on the requirement we differentiate between different

designs and type.

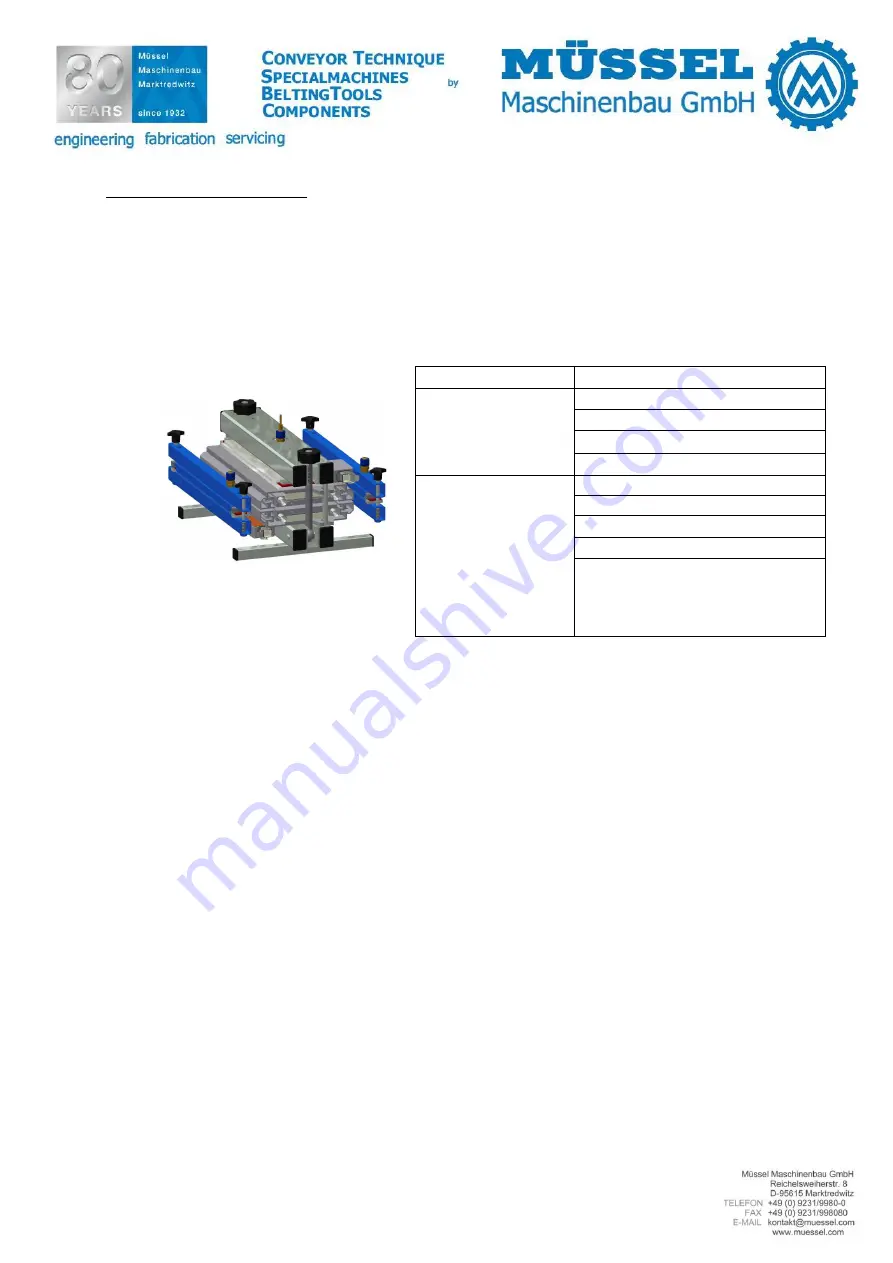

The heating press consists of the following components and functional groups:

Functional group

Components

Top part

Pressure beam

Pressure hose

Heating plate with edge cooling bar

Plug-in contact / cable

Bottom part

Pressure beam

Heating plate with edge cooling bar

Plug-in contact / cable

Eye bolts with nuts

Pneumatical hold-down bars (bot-

tom hold-down bar without pres-

sure hose / top hold-down bar with

pressure hose)

3.2

How it works

In the closed heating press pressure and temperature are generated between the top and bottom

part and the electrically heated heating plates when compressed air is supplied; this caused the

melting of the inserted belting material as well as the splicing after a prescribed period (hold-down-

time). Once cooled down, the finished splice has got the physical features required.

For further information on how the heating press functions, see chapter "5 Handling".