User’s Guide Kona / Kona apparel cutting plotter

Maintenance

174

AP-75370 - Revision 1.1

8.1.3

Cleaning the cutter blade

Use following procedure to remove small media particles in the base part of the cutting blade

holder.

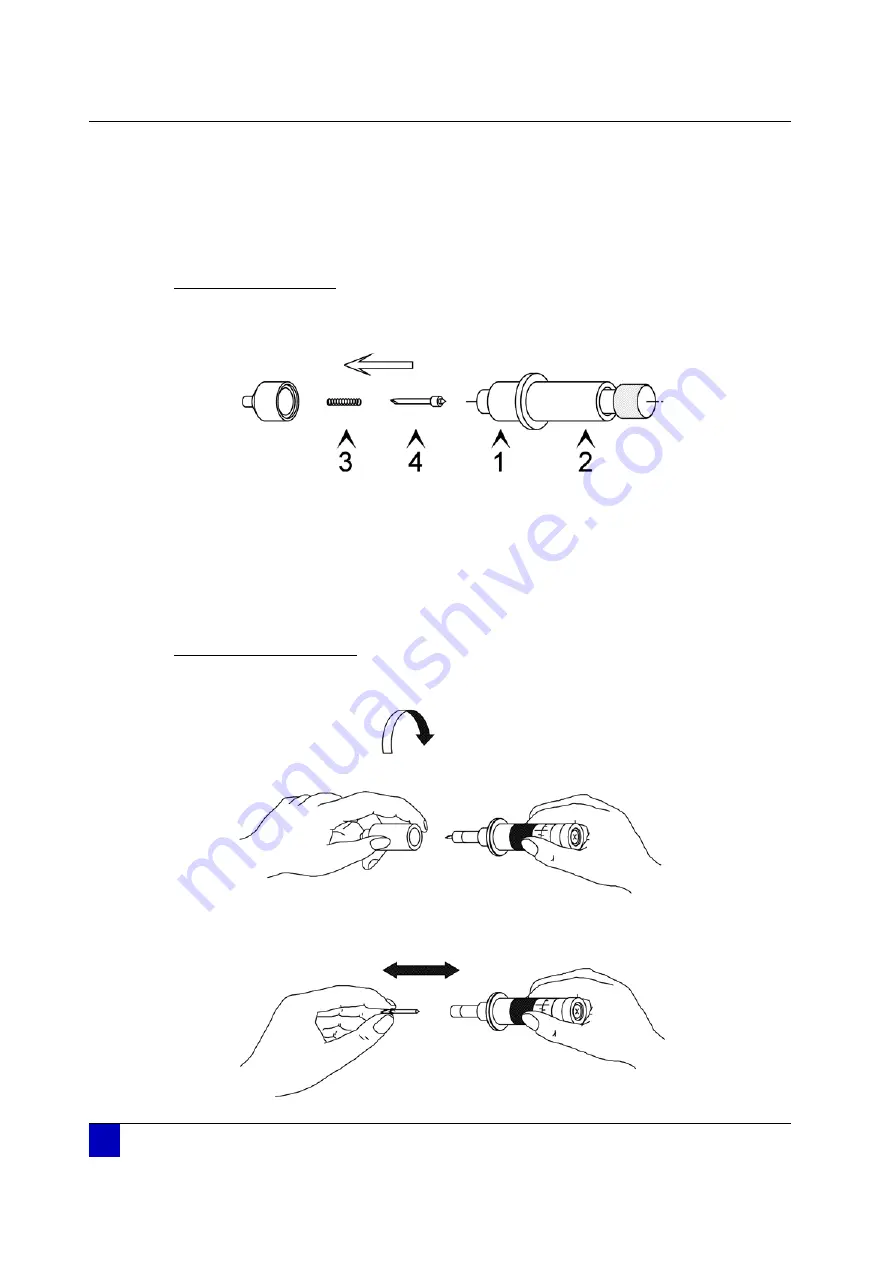

Standard knife holder

Step 1:

Hold the body (2) into one hand and unscrew the base part (1)

Step 2:

Remove the spring (3) and the cutting blade (4).

Step 3:

Blow away media particles accumulated in the top of the base part.

Step 4:

Remove the spring from the cutting blade and remove any residual material from

the blade tip

Step 5:

Place the spring back over the cutting blade and tightly screw the base part on the

body.

Knife holder with nonius

Step 1:

Take the body into one hand and remove the base part.

Step 2:

Blow away the media particles accumulated in the top of the base part.

Step 3:

Remove any residual material from the blade tip.

Summary of Contents for Kona 1400

Page 1: ...User s Guide...

Page 2: ......

Page 4: ...User s Guide Kona Kona apparel cutting plotter 4 AP 75370 Revision 1 1...

Page 10: ...User s Guide Kona Kona apparel cutting plotter 10 AP 75370 Revision 1 1...

Page 160: ...User s Guide Kona Kona apparel cutting plotter Contour cutting 160 AP 75370 Revision 1 1...

Page 176: ...User s Guide Kona Kona apparel cutting plotter Maintenance 176 AP 75370 Revision 1 1...

Page 208: ...208 AP 75370 Revision 1 1 User s Guide Kona Kona apparel cutting plotter Troubleshooting...

Page 212: ...User s Guide Kona Kona apparel cutting plotter Consumables 212 AP 75370 Revision 1 1...

Page 217: ......