Rockhopper II series printers – Maintenance Manual

51

AP-74065, Rev. 1.2, 27/09/04

Step 7 :

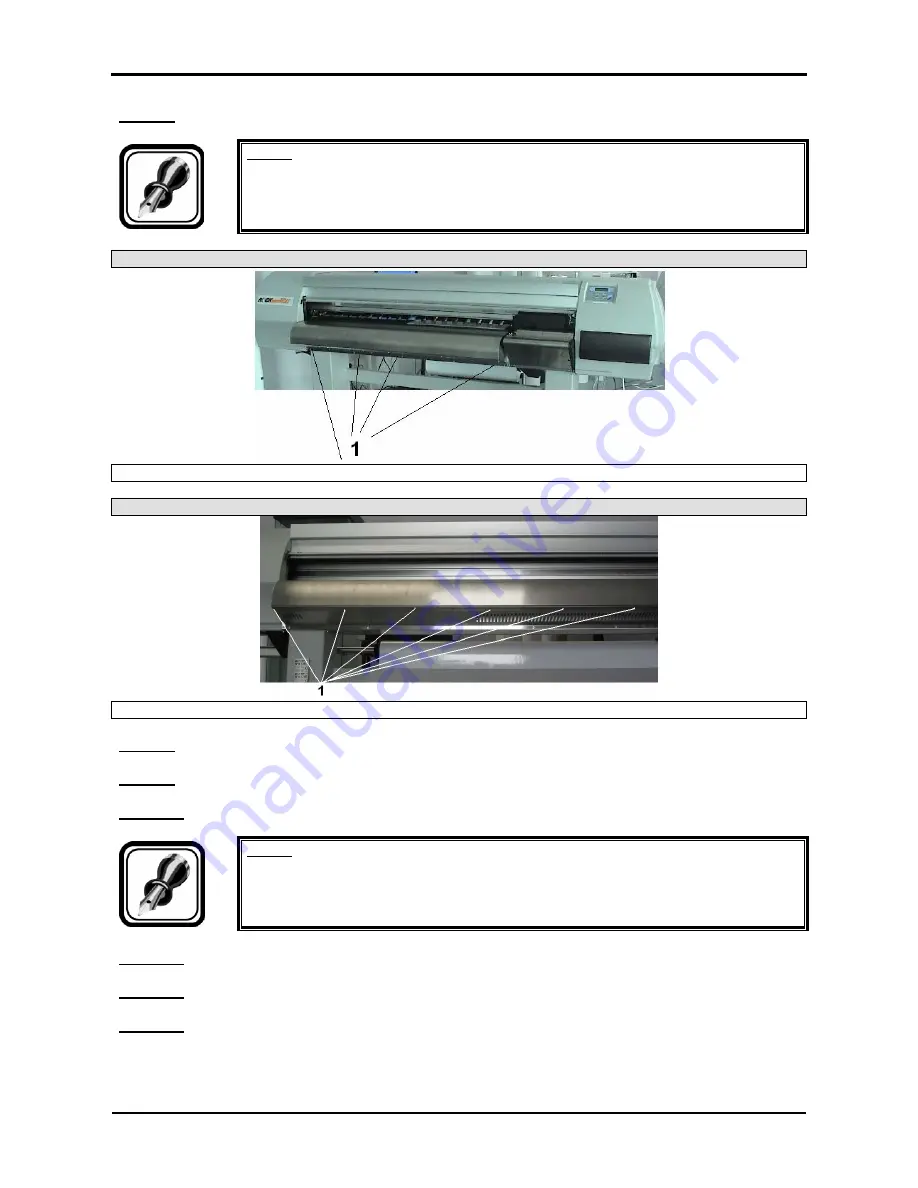

Remove the screws from the front of front media guide.

Notes :

¾

Please note that the amount of screws is size dependent.

Rockhopper II 2 heater

1 = Screws on the front of front media guide

Rockhopper II 4 heater

1 = Screws on the front of front media guide

Step 8 :

Standing before the unit move the front paper guide towards you.

Step 9 :

Loosen the cables from their cable clamps.

Step 10 :

Carefully loosen the connectors

Notes :

¾

Be sure not to damage the cables or connectors.

Step 11 :

Remove the front paper guide.

Step 12 :

Replace the parts inside the printer.

Step 13 :

Reinstall all parts in the opposite order of the removal procedure.

Summary of Contents for Rockhopper II 2H

Page 1: ...Maintenance Manual MUTOH EUROPE N V AP 74065 Rev 1 2 27 09 2004 ...

Page 3: ...Rockhopper II series printers Maintenance Manual 4 AP 74065 Rev 1 2 27 09 04 ...

Page 5: ...Rockhopper II series printers Maintenance Manual 6 AP 74065 Rev 1 2 27 09 04 ...

Page 7: ...Rockhopper II series printers Maintenance Manual 8 AP 74065 Rev 1 2 27 09 04 ...

Page 13: ...Rockhopper II series printers Maintenance Manual 14 AP 74065 Rev 1 2 27 09 04 ...

Page 29: ...Rockhopper II series printers Maintenance Manual 30 AP 74065 Rev 1 2 27 09 04 ...

Page 201: ...Rockhopper II series printers Maintenance Manual 202 AP 74065 Rev 1 2 27 09 04 ...

Page 255: ...Rockhopper II series printers Maintenance Manual 256 AP 74065 Rev 1 2 27 09 04 ...

Page 318: ...Rockhopper II series printers Maintenance Manual 319 AP 74065 Rev 1 2 27 09 04 ...