Maintenance Manual – SC Cutting Plotter

71

AP-74030, Rev / B

Step 3 :

Tighten screw #6 and check the detection position again.

6.3.15. Pressure roller UP/DOWN sensor : removal and installation.

Note :

This procedure is valid for all SC-series except for SC-550. For the SC-550 please refer

to 6.3.16. Pressure roller UP/DOWN sensor SC-550.

Step 1 :

Remove the right cover (Please refer to 6.2.1. Covers left and right).

Step 2 :

Open the PCB box (Please refer to 6.2.3. PCB box).

Step 3 :

Remove the sensor.

Note :

To reinstall the pressure roller UP/DOWN sensor perform above steps in reversed order.

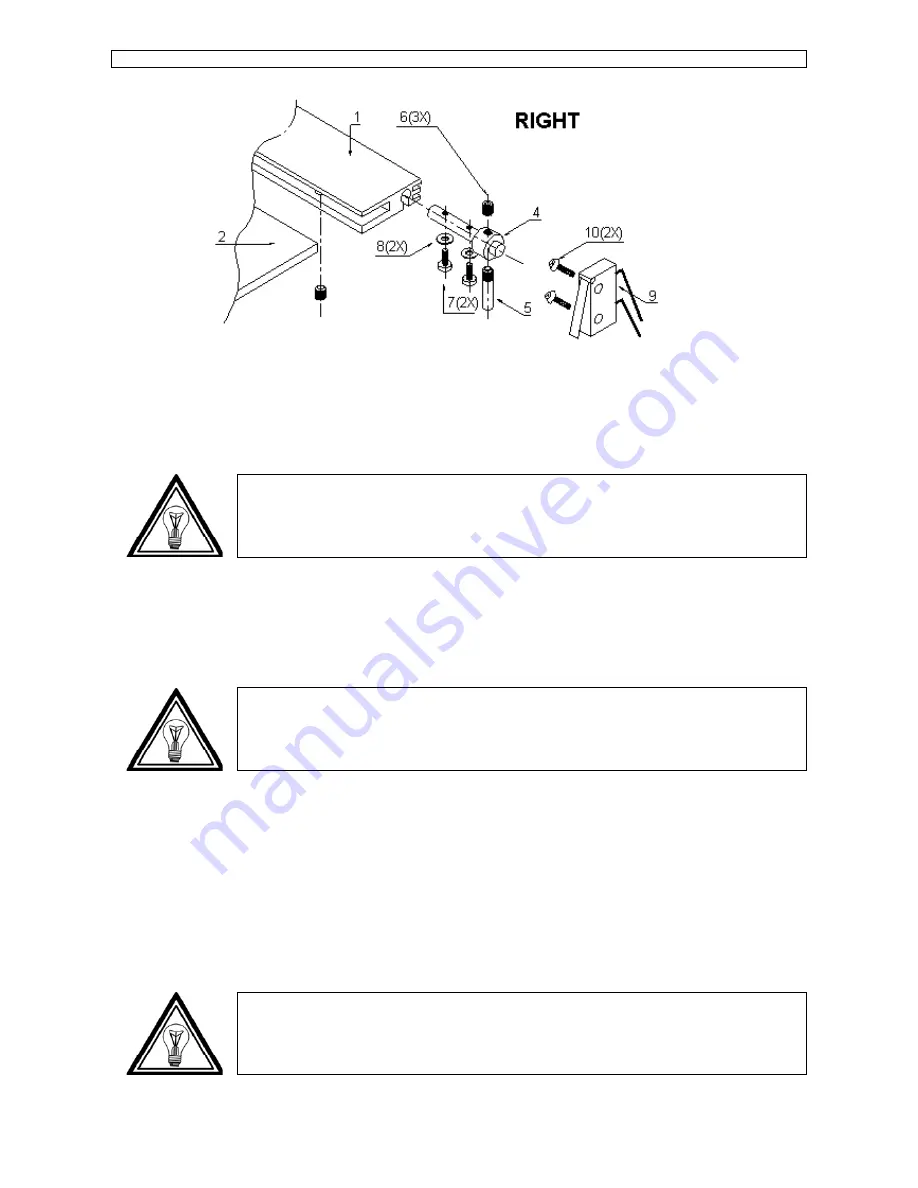

6.3.16. Pressure roller UP/DOWN sensor SC-550 : removal and installation.

Step 1 :

Remove the right cover (please refer to 6.2.1. Covers left and right).

Step 2 :

Remove the Up/DOWN lever knob and the Y-rail.

Step 3 :

Unplug the sensor cable connector from the terminal board.

Step 4 :

Remove the sensor by unscrewing 2 screws.

Note :

To reinstall the pressure roller UP/DOWN sensor perform above steps in reversed order.

Summary of Contents for SC-1000

Page 1: ...Maintenance Manual SC CUTTING PLOTTER MUTOH EUROPE N V AP 74030 Rev B...

Page 2: ...2 AP 74030 Rev B...

Page 4: ...4 AP 74030 Rev B...

Page 8: ...8 AP 74030 Rev B...

Page 12: ...Maintenance Manual SC Cutting Plotter 12 AP 74030 Rev B...

Page 15: ...Maintenance Manual SC Cutting Plotter 15 AP 74030 Rev B 2 3 Block diagram SC 550 1st version...

Page 16: ...Maintenance Manual SC Cutting Plotter 16 AP 74030 Rev B 2 4 Block diagram SC 550 2nd version...

Page 20: ...Maintenance Manual SC Cutting Plotter 20 AP 74030 Rev B...

Page 74: ...Maintenance Manual SC Cutting Plotter 74 AP 74030 Rev B...

Page 82: ...Maintenance Manual SC Cutting Plotter 82 AP 74030 Rev B 8 7 Pressure roller UP DOWN mechanism...

Page 92: ...Maintenance Manual SC Cutting Plotter 92 AP 74030 Rev B 8 15 Pressure roller assy...

Page 94: ...Maintenance Manual SC Cutting Plotter 94 AP 74030 Rev B 8 16 Cutting head assy...

Page 96: ...Maintenance Manual SC Cutting Plotter 96 AP 74030 Rev B...

Page 97: ...Maintenance Manual SC Cutting Plotter 97 AP 74030 Rev B...

Page 98: ...Maintenance Manual SC Cutting Plotter 98 AP 74030 Rev B...

Page 104: ...Maintenance Manual SC Cutting Plotter 104 AP 74030 Rev B 9 4 PCB box left and right SC 550...

Page 115: ...Maintenance Manual SC Cutting Plotter 115 AP 74030 Rev B 9 14 Pressure roller assy SC 550...

Page 117: ...Maintenance Manual SC Cutting Plotter 117 AP 74030 Rev B 9 15 Cutting head assy SC 550...

Page 118: ...Maintenance Manual SC Cutting Plotter 118 AP 74030 Rev B...

Page 119: ...Maintenance Manual SC Cutting Plotter 119 AP 74030 Rev B...

Page 120: ...Maintenance Manual SC Cutting Plotter 120 AP 74030 Rev B...