Installation

ValueCut USER MANUAL

16

VC2E-A-00

2.2 Stand & Flexible Media Support System (VC2-1300/1800)

Step 1

Please examine supplied items in the accessory box of stand carton:

1 set of roll media flange (2 pieces)

1 set of roll holder (2 pieces)

2 pieces of base beams

2 pieces of side beams

1 piece of stand beam

2 piece of roll holder support

20 pieces of M6 screws

1 piece of 4 mm L-shape hexagon screw driver

1 piece of Installation Guide for Stand Set

Step 2

Remove the plotter body and the accessories from the shipped carton.

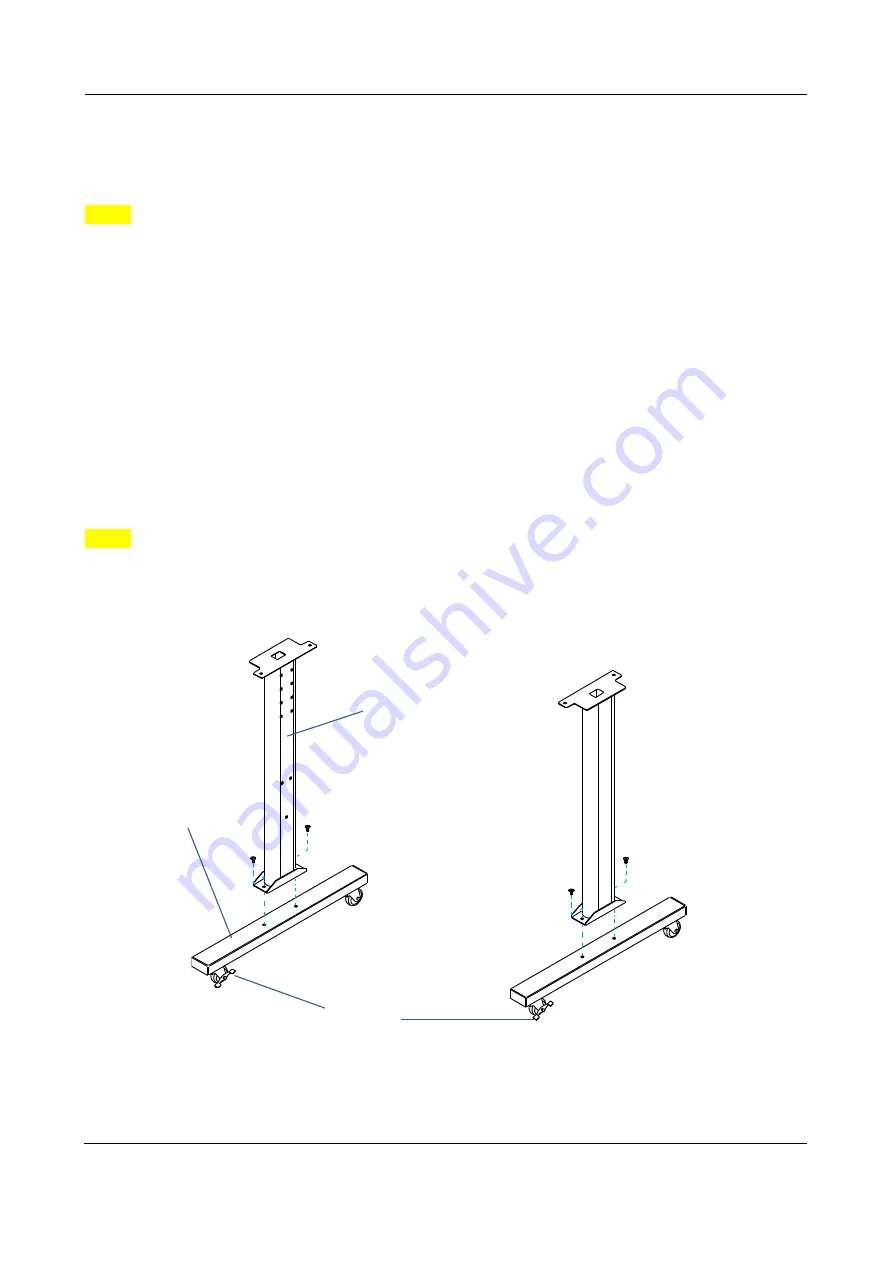

Assemble the base beam to the side beam with 2 screws to form a T-shape stand.

Figure 2-1

Front

Rear

Break

Front

Rear

Base beam

Side beam

Summary of Contents for ValueCut II Series

Page 60: ...Automatic Aligning System ValueCut USER MANUAL 60 VC2E A 00 Figure 5 1 Figure 5 2...

Page 111: ......

Page 112: ......