ValueCut User Manual

CorelDRAW Plug-In A-4

Contour cutting through CorelDraw

Step 1: Position the paper with registration marks printed by your printer on the cutter.

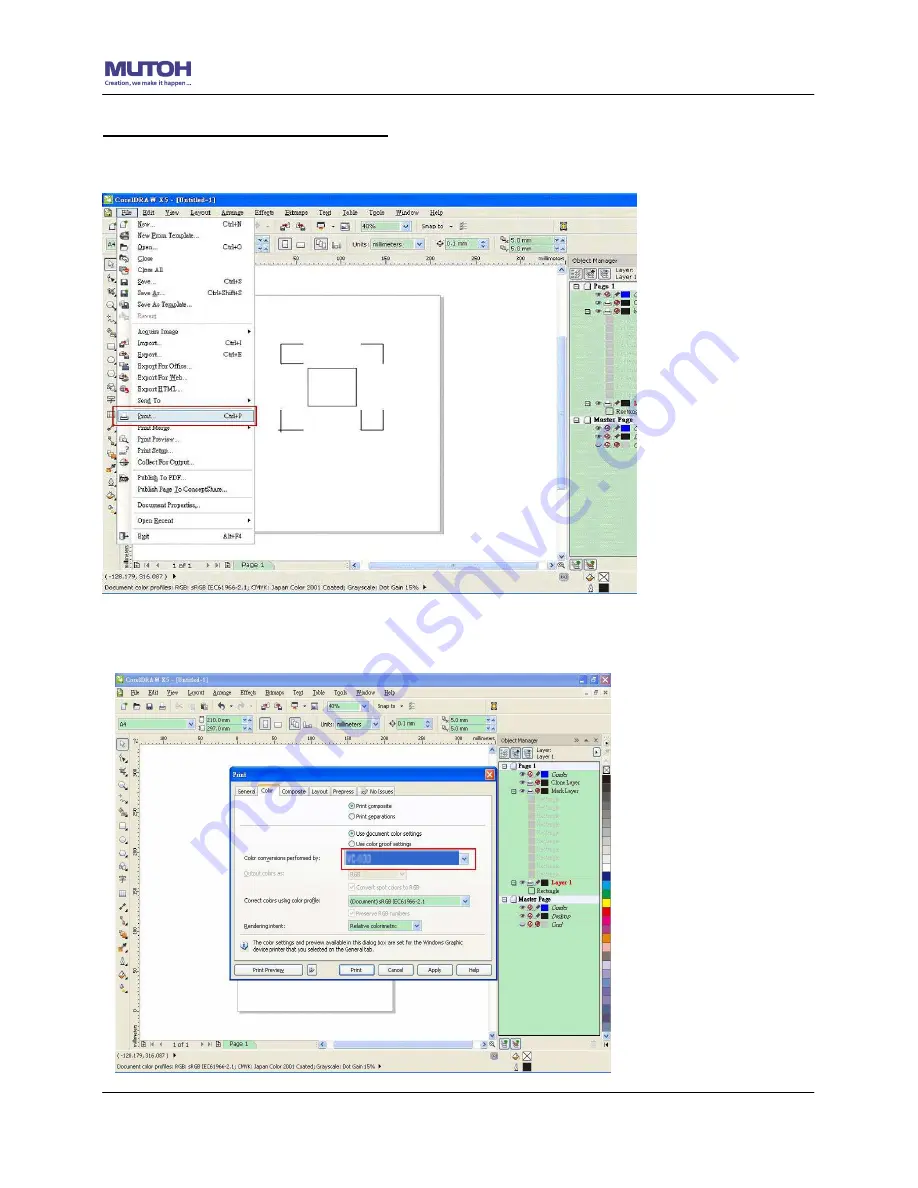

Step 2: Select “Files

Print”.

Please note that if you use CorelDraw X5, you must follow the steps below.

Click the “color” page and go to the “Color conversions performed by:” and then select the

model name of you cutter.