MAINTENANCE MANUAL

VCE-MM-02

55

Carriage locked, cannot move.

[Causation and recovery:]

The spring loading bearing of carriage is damaged. (Change the carriage set.)

The carriage belt is too tight. (Adjust the belt tension.)

Some fasten screws are loose so that the shaft bearing of carriage belt drops. (Fasten the

screws.)

The keyboard does not work.

[Causation and recovery:]

The connection between keyboard and main board is broken. (Re-plug the connector or change

the keyboard set.)

Dust or moist surface makes a bad keyboard contact. (Change the keyboard set.)

The machine makes noise when it is on the standby status.

[Causation and recovery:]

The screws of tool carriage cover are loose. (Fasten the screws.)

X or Y motor belt is loose. (Adjust the belt tension.)

The carriage belt is loose (Adjust the carriage belt tension)

The driver board set is damaged. (Change it.)

The machine makes abnormal noise from the drum set when it is running.

[Causation and recovery:]

X or Y motor belt is loose. (Adjust the belt tension.)

The driver board set is damaged. (Change it.)

The gear at the left of drum set is not tightly mounted on the shaft. (Change it.)

The screws that fasten the drum to the shaft are loose. (Fasten the screws.)

X or Y motor is damaged. (Change it.)

The tool carriage does not perform the up/down action.

[Causation and recovery:]

The blade holder is not installed properly. (Re-install it, please refer to user’s guide.)

The flat cable is broken. (Change it.)

The carriage PCB is damaged. (Change it.)

VCM is damaged. (Change the Carriage set.)

The encoder of the VCM is damaged. (Change the Carriage set.)

Summary of Contents for ValueCut VC-1300

Page 1: ...No VCE MM 02 Cutting Plotter VC 600 VC 1300 VC 1800 MAINTENANCE MANUAL...

Page 8: ...MAINTENANCE MANUAL VCE MM 02 8 A Main Unit Assembly Recommend Service Parts...

Page 10: ...MAINTENANCE MANUAL VCE MM 02 10 C Left End Assembly Recommend Service Parts...

Page 11: ...MAINTENANCE MANUAL VCE MM 02 11 D Right End Assembly Recommend Service Parts...

Page 12: ...MAINTENANCE MANUAL VCE MM 02 12 E X Motor Bracket and Belt Assembly Recommend Service Parts...

Page 13: ...MAINTENANCE MANUAL VCE MM 02 13 F Carriage Assembly Recommend Service Parts...

Page 14: ...MAINTENANCE MANUAL VCE MM 02 14 G Pinch Roller Assembly Recommend Service Parts...

Page 15: ...MAINTENANCE MANUAL VCE MM 02 15 H Main Beam Assembly Recommend Service Parts...

Page 16: ...MAINTENANCE MANUAL VCE MM 02 16 I Drum Assembly Recommend Service Parts...

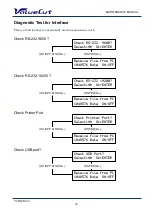

Page 17: ...MAINTENANCE MANUAL VCE MM 02 17 System Diagram and Components of Main Board...