5

tional), install the machine on

a flat, smooth and dry surface

suitable for supporting the

weight of the machine itself

plus the goods to be sliced. The

recommended height of the

worktop is approximately 80

cm. Lift the machine careful

-

ly and insert all the feet in the

specific lodgings in the base.

For some models, the front

support feet can be unscrewed

and placed in the desired posi

-

tion depending on the depth of

the worktop.

To prevent damage, some mod

-

els are packaged separately

from the disassembled fly

-

wheel during transport. If the

received machine flywheel is

not assembled, follow these in

-

structions:

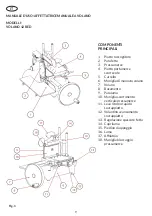

-

insert the flywheel on the

shaft, checking correct cor

-

respondence with the fly

-

wheel-shaft sleeve holes (Fig.

3-A);

-

insert the taper pin in the

sleeve with the tapered end

(smaller diameter) turned to

-

ward the sleeve itself (Fig. 3-B);

CAUTION!

If the pin is

correctly positioned, it

will insert almost entirely with

-

out being forced.

-

hammer down the pin to in

-

sert it fully.

OPERATION

-

Make sure that the blade is

properly protected from the

blade protection: use the blade

protection locking lever, if

present (Fig.4). Check that the

thickness adjustment knob is

in the safety position (position

“0”) (13);

-

if the handle is folded toward

the flywheel, lift it to the work

-

ing position, perpendicular to

the flywheel;

-

using the flywheel handle,

rotate the flywheel (7) to bring

the carriage (5) fully forward

(toward the operator);

-

pull back (away from the

blade) the meat table (4) using

the meat table advance mech

-

anism (12);

-

set the product to be sliced

on the meat table;

-

grip the handle to vertically

slide the product holder and

press it on the product;

-

grip the handle of the prod

-

uct holder arm and push it with

force on the product to lock it;

-

arrange the desired slice

thickness, rotating the knob at

the same time and selecting a

thickness;

-

move the meat table with

product forward (toward the

blade), using the meat table

rapid advance device (11) or

meat table advanced mecha

-

nism (12);

CAUTION!

Leave a space

of 0.5 - 1 cm between the

blade and the product.

-

uncover the blade guard, de

-

pending on the mode: a) pull

the locking lever, if present,

toward the operator, having it

rotate in the anticlockwise di

-

rection; b) loosen the locking

knob on the blade guard, pull

toward the operator, re-tight

-

en the knob to lock the blade

guard in its stand-by position

(blade uncovered);

CAUTION Sharp blade,

cutting hazard!

When

the blade is not covered by the

guard, be extremely careful to

keep your hands as far away

from the unprotected area as

possible.

-

activate the flywheel by hav

-

ing it rotate it in the clockwise

direction.

WARNING: risk of dam-

ages!

Never turn the fly

-

wheel anti-clockwise, reverse

flywheel rotation may serious

-

ly damage the machine.

-

during the return movement

of the carriage (towards the

operator) the meat table will

automatically move towards

the blade;

-

when the meat table gets to

limit advancing towards the

blade, stop slicing and lift up

the top clamp. Use the meat

table rapid advance device or

the meat table advance mech

-

anism to pull the meat table

away from the blade. Reposi

-

tion the product, relock it with

the top clamp and restart slic

-

ing.;

-

unload the product following

the operations in the reverse

order.

CAUTION Cutting haz-

ard!

After the cutting

operation has been completed,

turn the lever in the opposite

direction: the protective ring

will overlap the blade, elimi

-

nating the hazard.

CLEANING

Clean the machine at the end

of their use and always before

using, after a long period of

inactivity. Use cut and tear re

-

sistant gloves and perform all

operations with great care.

Products for cleaning:

use only water and biode

-

gradable mild detergent, us

-

ing a soft, spongy cloth and a

semi-rigid nylon brush for the

sharp areas of the plate and the

product holder. Do not clean

the machine with jets of water

or steam or similar methods.

DISMANTLING

-

Check that the guard is cover

-

ing the blade properly (9).

!

!

!

!

!

Summary of Contents for Axis VOLANO 12 RED

Page 2: ... Fig 3 A Fig 3 B Fig 4 Fig 6 Fig 7 Fig 5 A Fig 5 B Fig 5 C ...

Page 87: ......