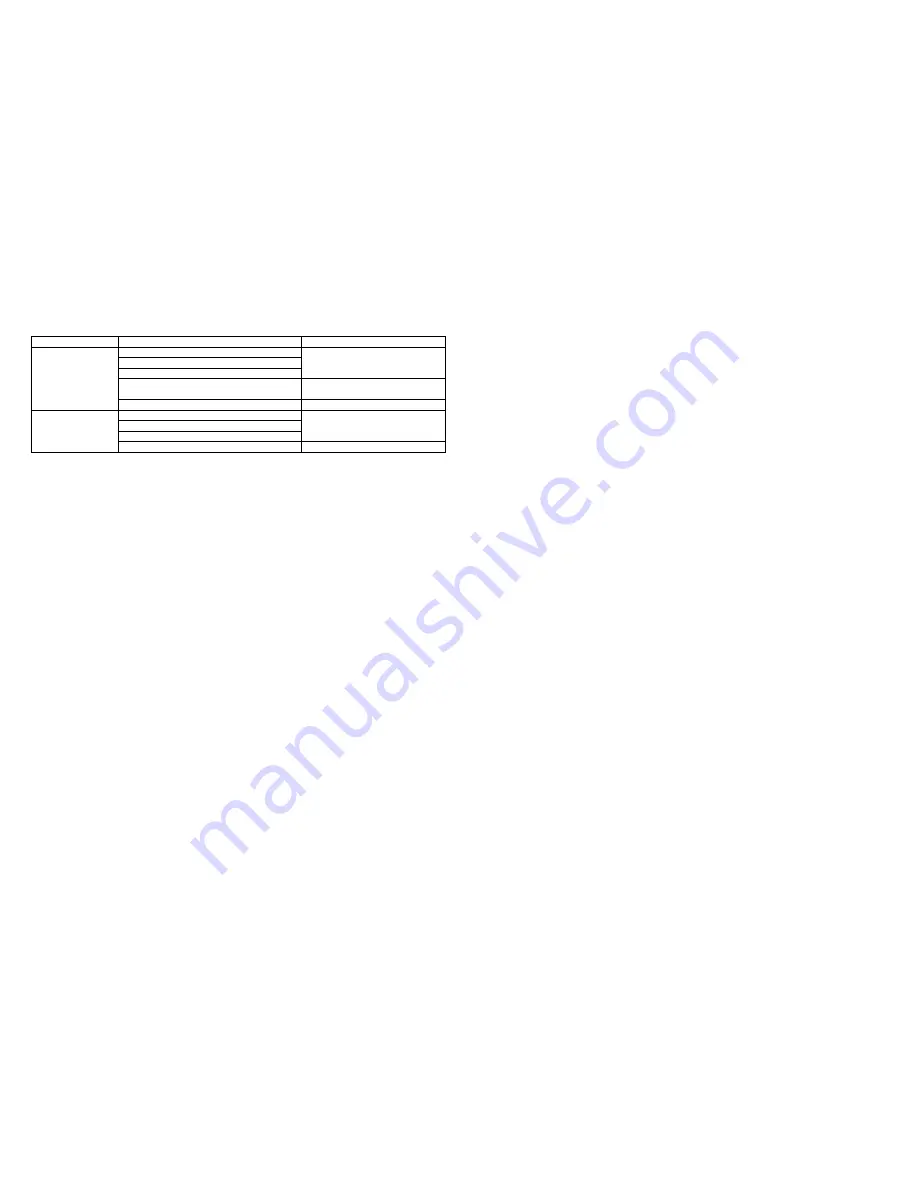

Area of Application

Motor Type

Model

Accumulator / Propeller

FUN-FLY 1,2 – 1,6 kg

FUN-FLY 1,3 – 1,7 kg

Acrobat 2 kg

3 Li-xx / 14x7“

4 Li-xx / 12x8“

4 Li-xx / 11x8“

Trainer 2,7 kg

3,0 kg

3 Li-xx / 13x8“

4 Li-xx / 11x7“

6,5 / 910

Quick model 1,4 kg

4xLi-xx / 8,5x6“

FUN-FLY 1,6 – 2,2 kg

Acrobat 2,6 kg

Trainer 3,5 kg

4 Lixx / 15x8“

5 Lixx / 13x8“

4 Li-xx 14x10“

8,0 / 680

Trainer 4,0 kg

5 Lixx / 12x8“

Safety Instructions

1)

Use the motor for designed purposes only.

2)

When operating models, follow regulations and laws effective in your country.

3)

The manufacturer is not responsible for possible damages caused by operation of models and devices

driven by the MVVS motors.

4)

Use only original spare parts.

5)

Never interfere into the motor structure.

6)

Before every flight check tightness of the propeller screw or chuck. If the propeller cone is used, check

its fixation as well. When mounting the cone, always follow appropriate instructions.

7)

Check attachment to the motor bed regularly. Never start up loosened motor!

8)

Use well balanced propellers only! Immediately replace damaged propellers or propellers that touched

the ground!

9)

Never stand so that parts of your body are in the plane with the rotating propeller. Apply the same

principle for bystanders.

10)

Never wear loose drifty clothing (tie, scarf, etc) when operating the model.

11)

Never try to stop the motor with any part of your body.

12)

Before starting the motor secure the model from setting in motion.

13)

Keep all small objects in the safe distance from the running motor and never throw any objects into it.

14)

When operating the motor, pay attention to keep possible bystanders, especially children, at least 10 m

away.

15)

Never rectify the axis bent during an accident but provide its replacement. Do not start the motor

immediately after an accident but check it first. The contaminated motor should be delivered to the

manufacturer for repair.

Motor Installation into a model

It is possible to mount the motors in two ways into the model. You can place the motor to the front of the model or

on the motor firewall (to model originally intended for combustion engines). The mounting holes span you see on

the drawing attached. In addition, drill at least 6 holes at least 8 mm in diameter for cooling air supply, so that to

be positioned directly opposite to inlets in the face of the installed motor.

Use at least 4 screws M3 for fixation, so that they penetrate min. 5mm and max. 7mm into the motor. In case

shorter screws are used, there is a danger of thread extraction. If longer screws are used, there is a danger of motor

seizure or mechanical damage. For motors designed to be driven by a combustion engine use the bed for rear

assembly supplied as an accessories with the motor. Never forget about holes for cooling air outlet, which is the

necessary condition for correct cooling function!

Solder on the electric wires to regulator and isolate the wiring.

Use adapter supplied with the motor or high-quality chuck adapters of 5mm inside diameter for gripping the

propeller. If an unsuitable or poor-quality adapter is used, the rotating propeller may slip off and cause serious

injury! Mount the supplied adapter, that the one of the fixing screws is bear on the flat part on the shaft.

Drive Optimisation

By means of correct choice especially of propeller, accumulator and controller parameters it is possible to change

driving unit properties within wide range and thus flight behaviour and attained flight time. Use data mentioned in

tables as guidance for your decision-making. In case other propeller is used than that mentioned it is necessary to

check max. current using a clip-on ammeter. Use the controller that will supply current values mentioned in

specifications with reserve. We recommend use of the 55 – 65A controller. The regulator advance should be set to

20° or higher and frequency to 8 kHz. As to supply accumulators do not exceed max. discharging currents because

there is a danger of destruction.

Do not overload the motor unnecessarily because there is a danger of damage or deterioration of performance

parameters. If the motor operates within the range recommended in technical specifications, its lifetime is limited

by mechanical endurance only.

Motor Maintenance

AC electric motors are not maintenance-demanding. The same applies to MVVS motors as well, as maintenance

only involves keeping the motor in dry and clean condition. If no accident happens, motor service life is only

limited by lifetime of bearings in hundreds of hours, depending on flying style and loading. Wear of bearings

shows by increased noise and radial allowance. Every accident may decrease bearing lifetime significantly. We

recommend entrusting the manufacturer with replacement of bearings.

If you decide to replace parts by yourselves, then always use original parts and MVVS tools only. Please note that

there is necessary to hold the airspace between the fixing ring and bearing of 0.1mm +- 0.05mm, if you decided to

disassemble the motor by yourself. Check regularly the screws of prop driver and fixing screws of they are

tighten enough. Change the prop driver after the motor crash. There is recommended to exchange the shaft

after the more serious crash.

.