25

EN

M1.3.BT200-BT200M.NLFREN 13112018

.1211 . V201301

- 5

–

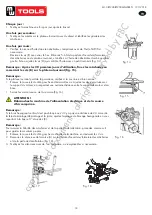

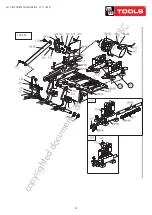

Lock the Hexagonal Vertical Mounting Arm, put the tyre on the rim, let

the Rocker Arm back to place as demounting the tyre. And let one side of

tyre down bead above the rear section of the Mounting/demounting head, the

other side under the front section of the Mounting/demounting head.

Suppress the trye with hands or help arm, and then spin the turntable for

mounting the tyre down bead.

Repeat the above operation for mounting the tyre up bead.

(Fig 7)

10. Helping arm application:

Helping arm at right side is auxiliary device of tyre changer for helping operator to demount and mount tyre.

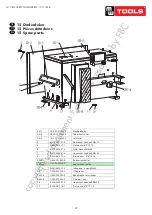

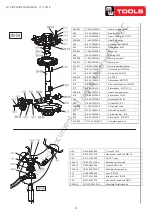

10.1 098 Help Arm Components

Each components of helping arm device are introduced as follows:

A- Swing arm B- Small helping arm

C- Roller C D- Raise-fall roller handle

F- Locking switch for right helping arm

G- Roller G

The function of helping arm control handle is as follows:

Roller lifting handle (D, Fig 8) is for lifting and lowering roller C

、

G so as to adjust

tyre demounting / mounting vertical height. Operate handle

(

D, Fig 8 ) up, then roller

C

、

G goes up

;

Operate handle

(

D, Fig 8 )down

,

then roller C

、

G goes down.

10.2 098 Help Arm Operation

It is difficult to demount and mount big and flat profile tyre. If operation is proper, it is very easy to use helping arm

device to demount and mount tyre from rim. The helping arm device may also be used

when demounting and mounting normal tyre with resistance.

a.

Clamp rim

Firstly, press both side tyre loose as per operation instruction in user’s manual. Force

of demounting and mounting is big when helping arm device is used. And rim may be

damaged easily. It is recommended that to clamp rim from outside

(

jaw protector may be

installed on jaws

)

. Tread relevant pedal to make jaws open to clamp edge of rim, move

helping arm’s rotary arm to far

-end. Put on tyre, tread relevant pedal to make jaws close

and to approach rim

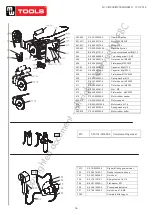

Fig 11

Fig 8

Fig 9

Fig 10

F

Fig 12

1

Fig 7

Fig. 11

.1211 . V201301

- 5

–

Lock the Hexagonal Vertical Mounting Arm, put the tyre on the rim, let

the Rocker Arm back to place as demounting the tyre. And let one side of

tyre down bead above the rear section of the Mounting/demounting head, the

other side under the front section of the Mounting/demounting head.

Suppress the trye with hands or help arm, and then spin the turntable for

mounting the tyre down bead.

Repeat the above operation for mounting the tyre up bead.

(Fig 7)

10. Helping arm application:

Helping arm at right side is auxiliary device of tyre changer for helping operator to demount and mount tyre.

10.1 098 Help Arm Components

Each components of helping arm device are introduced as follows:

A- Swing arm B- Small helping arm

C- Roller C D- Raise-fall roller handle

F- Locking switch for right helping arm

G- Roller G

The function of helping arm control handle is as follows:

Roller lifting handle (D, Fig 8) is for lifting and lowering roller C

、

G so as to adjust

tyre demounting / mounting vertical height. Operate handle

(

D, Fig 8 ) up, then roller

C

、

G goes up

;

Operate handle

(

D, Fig 8 )down

,

then roller C

、

G goes down.

10.2 098 Help Arm Operation

It is difficult to demount and mount big and flat profile tyre. If operation is proper, it is very easy to use helping arm

device to demount and mount tyre from rim. The helping arm device may also be used

when demounting and mounting normal tyre with resistance.

a.

Clamp rim

Firstly, press both side tyre loose as per operation instruction in user’s manual. Force

of demounting and mounting is big when helping arm device is used. And rim may be

damaged easily. It is recommended that to clamp rim from outside

(

jaw protector may be

installed on jaws

)

. Tread relevant pedal to make jaws open to clamp edge of rim, move

helping arm’s rotary arm to far

-end. Put on tyre, tread relevant pedal to make jaws close

and to approach rim

Fig 11

Fig 8

Fig 9

Fig 10

F

Fig 12

1

Fig 7

Fig. 12

10.1 Helping arm components

A. Swing arm

B. Small helping arm

C.

Roller C

D.

Raise-fall roller handle

F. Locking switch for right helping arm

G.

Roller G

The function of helping arm control handle is as follows:

Roller lifting handle (fig. 8, D) is for lifting and lowering roller C, G so as to adjust tyre

demounting / mounting vertical height.

•

Operate handle (fig. 8, D) up, then roller C, G goes up.

•

Operate handle (fig. 8, D)down, then roller C, G goes down.

10.2 Helping arm operation

It is difficult to demount and mount big and flat profile tyre. If operation is proper, it is very

easy to use helping arm device to demount and mount tyre from rim. The helping arm device

may also be used when demounting and mounting normal tyre with resistance.

A Clamp rim

1. Press both side tyre loose as per operation instruction in user’s manual. Force of

demounting and mounting is big when helping arm device is used. Rim may be

damaged easily. It is recommended to clamp rim from outside (jaw protector may be

installed on jaws).

2.

Tread relevant pedal to make jaws open to clamp edge of rim, move helping arm’s

rotary arm to far-end.

3. Tread relevant pedal to make jaws close and to approach rim.

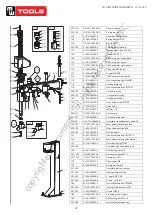

B Demount tyre

1.

Press tyre with right pressing roller C, G to a position 3 cm lower than rim edge, lubricate tyre bead, rotate turntable, lift

roller C, G. (fig 9).

2.

Move demounting/mounting head close to edge of rim, keep a 2-3 mm gap between demounting/mounting head and rim

plane, operate locking handle (fig. 4, K) to lock vertical arm, adjust screw bolt in column to position swing arm, make sure

2-3 mm gap between demounting/mounting head and rim edge side.

3.

Nearby demounting/mounting head, insert lift lever N into tyre, use lift lever to lift bead upon knob of demounting /

mounting head. Manually rotate roller C to inner side, pull handle D down, make roller C to press rim, keep 3-5 mm gap

between demounting/mounting head and rim, make sure demounting/mounting head not damage rim, rotate turntable,

demount tyre upper bead (fig 11).

4.

Push handle D up, lift roller C,G, press switch F, loosen right pressing arm, lift tyre up, insert lifting level into bottom tyre

bead nearby demounting/mounting head, lift bead upon knob of demounting / mounting head and rotate turntable to

demount down tyre bead.

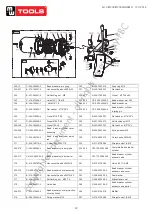

C Mount tyre

1. Lubricate tyre and rim edge with lubricant to avoid damage of tyre. Adjust height of demounting/mounting head and

make tyre bottom bead upon rear of demounting/mounting head and below front of demounting/mounting head. Rotate

turntable to mount bottom bead.

2.

Make tyre top bead upon rear of demounting/mounting head and below front of demounting/mounting head, move

right pressing arm and make sure it is locked, pull handle D down to make roller C,G to press top bead to position below

demounting/mounting head. Lock pressing block 1 on rim edge, rotate turntable, finish tyre mounting (fig 12).

copyrighted

document

- all

rights

reserved

by

FBC