M1.3.BT200-BT200M.NLFREN 13112018

4

NL

7 Installatie van de machine

1. Draai de moeren aan de bodem los. Plaats de machine en zorg ervoor dat deze

horizontaal is. Monteer de machine met alle schroeven, en zorg ervoor dat deze

stabiel is. Let erop dat de elektrische installatie met een goede aarding uitgerust is, om

lekkages te voorkomen. De vloer moet antislip zijn.

2.

Draai de moer A op het frame B los, zoals in afbeelding 3 getoond. Til de kolom

C op. Monteer deze op het frame B door de moer A en de bout op het frame B te

gebruiken. Als de kolom na een tijdje losgaat, maak deze onmiddellijk opnieuw vast,

anders kan de band beschadigd worden.

8 Elektrische en pneumatische aansluitingen

AANDACHT!

Voor de installatie en de aansluiting, zorg ervoor dat de elektrische

installatie voldoet aan de technische gegevens van de machine.

De elektrische en pneumatische aansluitingen moeten door een

gekwalificeerde elektricien uitgevoerd worden.

Verbind de persluchtaansltuiting aan de rechterkant van de machine met uw

persluchtsysteem. Het elektriciteitsnet waaraan de machine aangesloten wordt, moet

met een stroomonderbreker en een aarding uitgerust zijn. Installeer de automatische

veiligheidsschakelaar op de hoofdvoeding. De lekstroom is op 30A vastgesteld.

AANDACHT!

Er is geen stekker op die machine. De gebruiker moet zelf een

stekker van tenminste 16 A installeren, die met de spanning van

de machine overeenkomt. Hij kan ook de machine rechtstreeks

aansluiten volgens bovenstaande vereisten.

.1211 . V201301

- 2 -

3. Technical data

External locking rim dimensions

10~21

"

Internal locking rim dimensions

12~24

"

Max. Wheel diameter

1040mm(41

"

)

Max. Wheel width

355mm(14

"

)

Working Pressure

8-10bar

Power supply

110V (1ph)/ 220V (1ph)/ 380V (3ph)

Optional Motor power

0.75/0.55/1.1 kw

Max. Rotating Torque (Turntable)

1078 Nm

Overall Dimension

96*76*93cm

Noise Level

75 Db

Remark

:

Rim dimensions defined at above table are based on the iron wheel rims. Aluminum rims are thicker than the

iron wheel rims, so here above rim dimensions are just for the reference.

Here above machine versions can be equipped with Rapid Tire Inflation Device (client optional device),

IT-suffix version, accessory details can be found at the IT-suffix version exploded drawing.

4. Transport:

When transporting, the machine should be with original package and placed according to the mark on the package.

For the already packaged machine should be handled with a corresponding tonnage forklift for loading and unloading.

The location to insert the fork feet shown as

Fig 1

5. Unpacking & Inspection:

Pull out the nail which is nailed on the plate with tip jaw; unpack the carton and plastic cover. Check and make sure

all parts shown on the spare parts list are included. If any parts are missing or broken, please do not use the machine

and contact the manufacturer or dealer ASAP.

Fig 1 Fig 2 Fig 3

6. Workplace requirements:

Choose workplace in compliance with safety regulations. Connect power supply and air source according to manual

and workplace must have good air condition; in order to make the machine run well, its workplace requires at least

clear space from each wall shown as

Fig 2

. If installing it outdoor, it must be protected by roof against rain and

sunshine.

Warning: the machine with motor must not be operated in explosive atmosphere

.

Afb. 1

.1211 . V201301

- 2 -

3. Technical data

External locking rim dimensions

10~21

"

Internal locking rim dimensions

12~24

"

Max. Wheel diameter

1040mm(41

"

)

Max. Wheel width

355mm(14

"

)

Working Pressure

8-10bar

Power supply

110V (1ph)/ 220V (1ph)/ 380V (3ph)

Optional Motor power

0.75/0.55/1.1 kw

Max. Rotating Torque (Turntable)

1078 Nm

Overall Dimension

96*76*93cm

Noise Level

75 Db

Remark

:

Rim dimensions defined at above table are based on the iron wheel rims. Aluminum rims are thicker than the

iron wheel rims, so here above rim dimensions are just for the reference.

Here above machine versions can be equipped with Rapid Tire Inflation Device (client optional device),

IT-suffix version, accessory details can be found at the IT-suffix version exploded drawing.

4. Transport:

When transporting, the machine should be with original package and placed according to the mark on the package.

For the already packaged machine should be handled with a corresponding tonnage forklift for loading and unloading.

The location to insert the fork feet shown as

Fig 1

5. Unpacking & Inspection:

Pull out the nail which is nailed on the plate with tip jaw; unpack the carton and plastic cover. Check and make sure

all parts shown on the spare parts list are included. If any parts are missing or broken, please do not use the machine

and contact the manufacturer or dealer ASAP.

Fig 1 Fig 2 Fig 3

6. Workplace requirements:

Choose workplace in compliance with safety regulations. Connect power supply and air source according to manual

and workplace must have good air condition; in order to make the machine run well, its workplace requires at least

clear space from each wall shown as

Fig 2

. If installing it outdoor, it must be protected by roof against rain and

sunshine.

Warning: the machine with motor must not be operated in explosive atmosphere

.

Afb. 2

.1211 . V201301

- 2 -

3. Technical data

External locking rim dimensions

10~21

"

Internal locking rim dimensions

12~24

"

Max. Wheel diameter

1040mm(41

"

)

Max. Wheel width

355mm(14

"

)

Working Pressure

8-10bar

Power supply

110V (1ph)/ 220V (1ph)/ 380V (3ph)

Optional Motor power

0.75/0.55/1.1 kw

Max. Rotating Torque (Turntable)

1078 Nm

Overall Dimension

96*76*93cm

Noise Level

75 Db

Remark

:

Rim dimensions defined at above table are based on the iron wheel rims. Aluminum rims are thicker than the

iron wheel rims, so here above rim dimensions are just for the reference.

Here above machine versions can be equipped with Rapid Tire Inflation Device (client optional device),

IT-suffix version, accessory details can be found at the IT-suffix version exploded drawing.

4. Transport:

When transporting, the machine should be with original package and placed according to the mark on the package.

For the already packaged machine should be handled with a corresponding tonnage forklift for loading and unloading.

The location to insert the fork feet shown as

Fig 1

5. Unpacking & Inspection:

Pull out the nail which is nailed on the plate with tip jaw; unpack the carton and plastic cover. Check and make sure

all parts shown on the spare parts list are included. If any parts are missing or broken, please do not use the machine

and contact the manufacturer or dealer ASAP.

Fig 1 Fig 2 Fig 3

6. Workplace requirements:

Choose workplace in compliance with safety regulations. Connect power supply and air source according to manual

and workplace must have good air condition; in order to make the machine run well, its workplace requires at least

clear space from each wall shown as

Fig 2

. If installing it outdoor, it must be protected by roof against rain and

sunshine.

Warning: the machine with motor must not be operated in explosive atmosphere

.

Afb. 3

.1211 . V201301

- 3

–

7. Position and installation:

1. Unscrew the nuts at the bottom, position the machine and calibrate it with the

horizontal rule. Mount the machine with all the screws and to ensure the machine is

stable. Make sure the system is equipped with a good grounding circuit for prevent

electric leakage. And have operation range of ground for skid prevention.

2. Unscrew the nut A on the cabinet body B as shown in

Fig 3

.

Lift the column C; mount it on the machine body B by using the nut A through the

bolt located on the machine body B. If the column becom

e

s loose after a period of

using, tight them immediately. Otherwise the result of damage to the tyre may

happen.

8. Electricity and Pneumatic connections:

Caution: Before installation and connection, check to be sure that the electricity

power supply corresponds to the machine technical data. All the installation of

electric and pneumatic devices must be operated by a professional electrician

.

Connect the compressed air connector which is on the machine right side with

compressed air system. The electric grid that the machine connects to must have

fuses protection device and good outer cover grounding protection. Install the

leakage automatic air switch on the maim power supply, leakage current is set at 30A

Caution: No power plug for this machine, the user should self-connect one power plug no less than 16A as well

as in line with the machine voltage. Or directly connect with the power supply according to the above

requirements

.

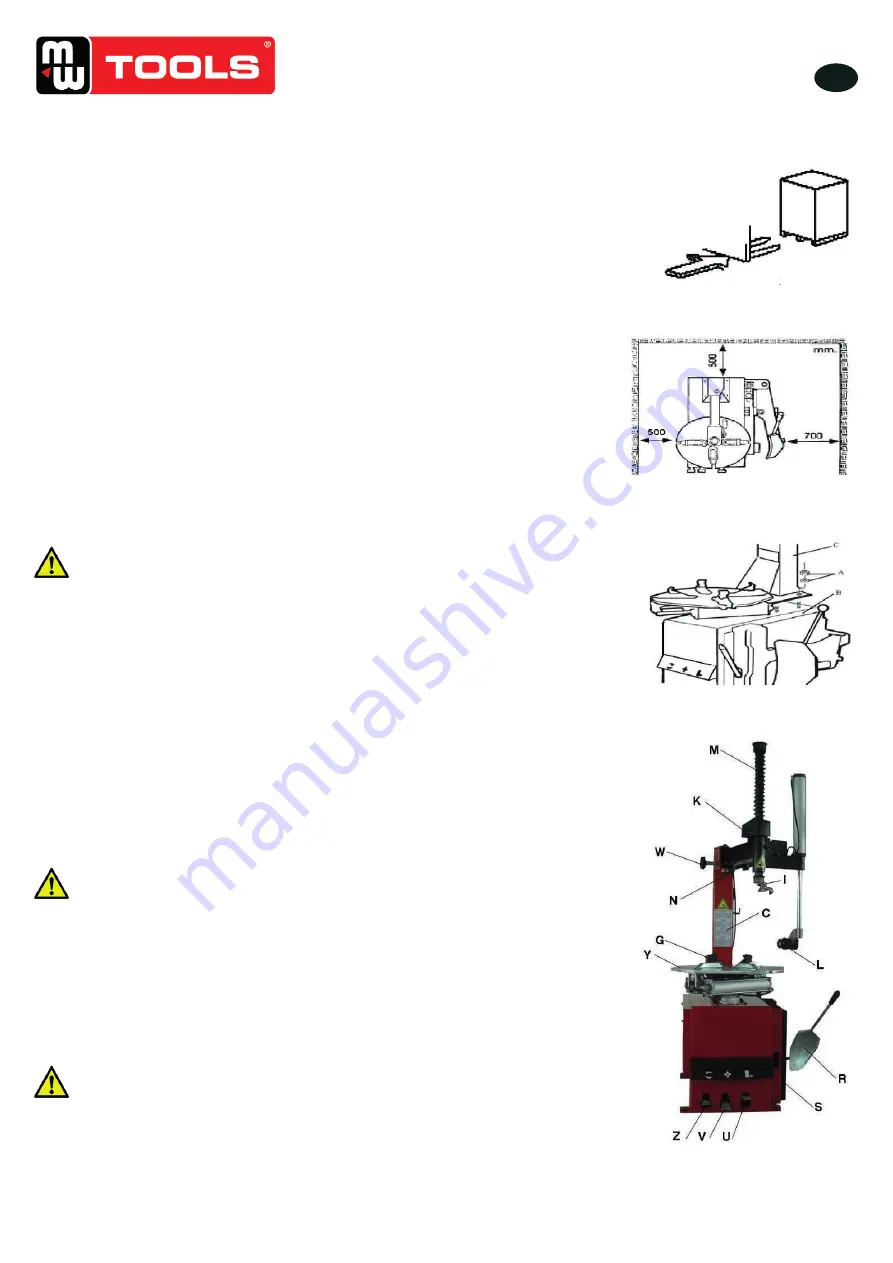

9. Adjusting operation:

Turntable Rotation Pedal (Z)

Bead Breaker Pedal (U)

Jaws open and close Pedal (V)

1)

Tread the Turntable Rotation Pedal (Z), Turntable (Y) clockwise rotation; Lift up the Turntable Rotation

Pedal (Z), Turntable (Y) counterclockwise rotation.

2)

Tread Bead Breaker Pedal (U), Bead Breaker shovel (R) close toward inside; release Bead Breaker Pedal (U),

Bead Breaker shovel (R) return to original position.

3)

Tread Jaws open and close Pedal (V), four clamps (G) on the turntable open; tread again, four clamps (G)

close. When the pedal is in the middle position, the four clamps stop moving.

Tyre changer operation is consisted of three parts:

1

)

Breaking the tyre bead

2

)

Demounting the tyre

3

)

Mounting the tyre

Caution: Before any operations, don

’

t wear loose clothing and wear protective hat, gloves, and skid-proof shoes.

Ensure to exhaust the air in the tyre completely, and remove all the wheel weights from the rim.

Fig 4

Afb. 4

4 Transport

De machine moet in de originele verpakking vervoerd worden, en geplaatst volgens de

markering op de kist. De verpakte machine moet vervoerd, verplaatst en neergelegd

worden door een vorkheftruck met voldoende capaciteit. Afbeelding 1 toont hoe de vork

geplaatst moet worden.

5 Uitpakken en inspectie

Met een tang, verwijder de spijker van de plaat. Verwijder het karton en het kunststof

deksel. Vergelijk de inhoud van de verpakking met de paklijst. Als een onderdeel

ontbreekt of beschadigd is, gebruik de machine niet en neem onmiddellijk contact op met

uw verdeler.

6 Vereisten voor de installatieplaats

Zorg ervoor dat de werkruimte in overeenstemming is met de veiligheidsvoorschriften. Sluit

de elektrische voeding en de persluchtbron volgens de instructies, en zorg ervoor dat de

werkplaats goed geventileerd wordt. Maak zeker dat er voldoende ruimte is rondom de

machine, zoals in afbeelding 2 getoond. Als de machine buiten geïnstalleerd wordt, moet

deze tegen regen en zonlicht beschermd worden.

AANDACHT!

De machine met motor mag niet in een explosieve omgeving

geïnstalleerd worden.

copyrighted

document

- all

rights

reserved

by

FBC