15

PPH75B - NLFREN - v1.1 - 29052017

FR

10

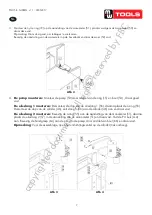

Figure 1

Assemble the nylon ring (71) to gauge fitting (51), then put the pressure gauge (50)

and twist tight. Remark: twist as tight as possible, otherwise it will be leak. Attach the

gauge fitting to the suitable upper cross beam and twist nut (52)

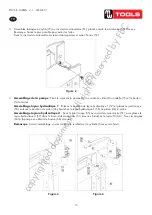

Figure 2

Pump assemble: attach the pump assy’ (53) to frame by using washer (15) and bolt

(54) and twist tight.

Hydraulic hose 1 assemble: dismantle the plug from Hydraulic hose 1 (57) then

assemble the o-ring(55), also dismantle the plug from ram assy’(46), connect the

Hydraulic hose 1 (56) to ram assy’(46) and twist tight.

Hydraulic hose 2 assemble: attach the o-ring (55) to gauge fitting (51), then put the

Hydraulic hose 2(57) into the gauge fitting (51) and twist tight, connect the PU pipe

(A-A). Attach the handle (64) to the pump pin by using bolt (65) and twist tight.

Remark: before assemble, open the breather valve first which is on the cylinder (pull

up the breather valve).

3. Assemblez la bague en nylon (72) au raccord du manomètre (51), placez ensuite le manomètre (50) et serrez.

Remarque: Serrez le plus possible pour éviter les fuites.

Fixez le raccord du manomètre sur le montant supérieur et serrez l’écrou (52).

4.

Assemblage de la pompe

: Fixez le corps de la pompe (53) au cadre en utilisant la rondelle (15) et le boulon

(54) et serrez.

Assemblage tuyau hydraulique 1

: Enlevez le bouchon du tuyau hydraulique 1 (57) et placez le joint torique

(55), enlevez le bouchon du piston (46), branchez le tuyau hydraulique 1 (56) au piston (46) et serrez.

Assemblage tuyaux hydraulique 2

: Fixez le joint torique (55) au raccord du manomètre (51), puis placez le

tuyau hydraulique 2 (57) dans le raccord du manomètre (51) et serres. Branchez le tuyau PU (A-A) . Fixez la poignée

(64) à la pompe en utilisant le boulon (66) et serrez.

Remarque

: Avant l’assemblage, ouvrez d’abord le reniflard sur le cylindre

(Tirez vers le haut).

11

Figure3

Figure 4

Move the hand winch (12) to the outside of the post, then use bolt (02), washer (06),

lock washer (05), and nut (04) which were dismantled just now to twist tight and fix to

the relevant roller.

Figure 5

3.6 Commissioning the machine

Before the commissioning

Before the first use, please fix the machine to the floor by anchor bole. It must be

ensured that the standing surface of the machine site is firm and horizontal, and that

sufficient lighting is provided for.

Clean the machine thoroughly

Before first use of this product, pour a teaspoon of good quality, air tool lubricant into

the air supply inlet of the lift control valve, connect to air supply to air supply and

copyrighted

document

- all

rights

reserved

by

FBC