24

PPH75B - NLFREN - v1.1 - 29052017

EN

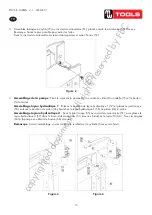

5. Move the hand winch (12) to the outside of the post, then use bolt (02), washer (06), lock washer (05), and nut (04)

which were dismantled just now to twist tight and fix to the relevant roller.

11

Figure3

Figure 4

Move the hand winch (12) to the outside of the post, then use bolt (02), washer (06),

lock washer (05), and nut (04) which were dismantled just now to twist tight and fix to

the relevant roller.

Figure 5

3.6 Commissioning the machine

Before the commissioning

Before the first use, please fix the machine to the floor by anchor bole. It must be

ensured that the standing surface of the machine site is firm and horizontal, and that

sufficient lighting is provided for.

Clean the machine thoroughly

Before first use of this product, pour a teaspoon of good quality, air tool lubricant into

the air supply inlet of the lift control valve, connect to air supply to air supply and

3.5 Commissioning the machine

Before the commissioning

Before t

he first use, please fix the machine to the floor by anchor bolt. It must be ensured that the standing surface of the

machine site is firm and horizontal, and that sufficient lighting is provided for.

1. Clean the machine thoroughly.

2.

Before first use of this product, pour a teaspoon of good quality, air tool lubricant into the air supply inlet of the lift

control valve, connect to air supply to air supply and operate for 3 seconds to evenly distribute lubricant.

3. Purge away air from the hydraulic system.

- Manual operation system: open the release valve by turning it counterclockwise. Pump several full stokes to eliminate

any air in the system.

- Air operating system: open the release valve by turning it counterclockwise. Connect the quick coupler-male into

the air supply hose quick coupler-female, then turn on the air valve with shield (61) letting the pump work for several

times to eliminate any air in the system.

4. Check all parts and conditions, if there is any part broken, stop using it and contact your supplier immediately.

4 Operation

1. Ensure

bed frame at proper position and lock the bed frame by pins (18) firmly.

2. Place the heel block (32) on bed frame (31), then insert workpiece onto the heel block.

Note

: The steel block must be used per pair, not by piece!

The steel block can be used by both sides.

3.

Close the release valve (P16) by turning it clockwise until it is firmly closed.

4.

Connect the air hose fitting (75) into the junction of air source, turn on the air valve (61) to let the pump work until

serrated saddle (49) nears workpiece, then turn off the air valve.

When air source is unavailable, pump the handle (64) until serrated saddle (49) nears workpiece.

5. Align workpiece and ram to ensure center loading.

6. Turn on air valve (or pump handle) to apply load onto workpiece (please see numeration in pressure gauge).

7. When work is done, turn off the air valve (or stop pumping handle), slowly and carefully remove load from

workpiece by turning the release valve (P16) counterclockwise in small increments.(must turn with the small angle, the

biggest is two circles)

8. Once ram has fully retracted, remove workpiece from bed frame.

9.

Disconnect the air inlet fitting from the air source.

copyrighted

document

- all

rights

reserved

by

FBC