10

M1.2.ME15W-ME20W.NLFREN 30032018

EN

MACH

1 Safety

1.1 Proper use

The bench grinder is exclusively designed for grinding and polishing metals with abrasive grinding wheels. The use of the

grinder for another purpose is forbidden and invalidates the guarantee. In addition, the manufacturer does not take any

reliability in case of damage and/or injury caused by an unconventional use of the machine.

Materials that are hazardous to health or materials that generate harmful dust may not be worked with the machine.

Any modification of the machine is forbidden and invalidates the guarantee.

It is also a part of proper use that the operator uses the machine in the range of its capacities, observes the instructions of this

manual about safety, operation and maintenance.

Contents

1 Safety ..............................................................................................................................................10

1.1 Proper use ........................................................................................................................................................10

1.2 General safety rules ...........................................................................................................................................11

1.3 Specific safety rules

..........................................................................................................................................11

2 Description of the machine ............................................................................................................... 12

2.1 General description ...........................................................................................................................................12

2.2 Technical data ..................................................................................................................................................12

3 Installation ......................................................................................................................................12

3.1 Site requirements ...............................................................................................................................................12

3.2 Assembly..........................................................................................................................................................12

4 Operation ........................................................................................................................................13

4.1 Before beginning work .......................................................................................................................................13

4.2 Operation ........................................................................................................................................................13

5 Changing the grinding wheel or brush ............................................................................................. 13

6 Spare parts ......................................................................................................................................14

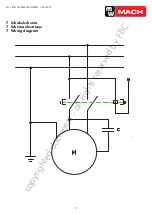

7 Wiring diagram ............................................................................................................................... 17

8 EC declaration of conformity ............................................................................................................18

copyrighted

document

- all

rights

reserved

by

FBC